An industrial automatic buckwheat shelling equipment

An industrial automation and buckwheat husk technology, which is applied in grain husking, agriculture, grain processing, etc., can solve the problems of buckwheat kernels with many impurities, failure to achieve husking, and incomplete husking, and achieve reasonable and novel design, simple structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

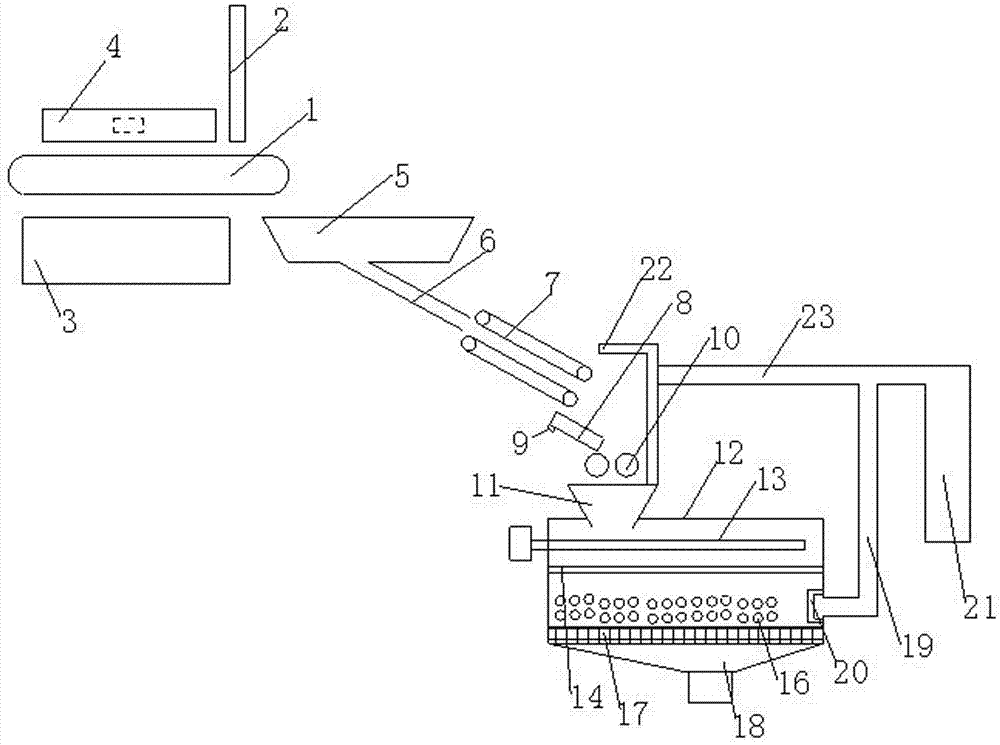

[0012] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

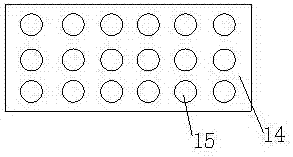

[0013] like Figure 1-2 As shown, the present invention is a kind of industrial automatic buckwheat hulling equipment, comprising a feed conveyor belt 1, a baffle plate 2 is arranged at the discharge end of the feed conveyor belt 1, and a baffle plate 2 is arranged at the lower end of the feed conveyor belt 1 An impurity tank 3 is also provided, and a pusher plate 4 driven by a cylinder is arranged on one side above the feed conveyor belt 1, and the pusher plate 4 pushes impurities into the impurity tank 3, and the baffle plate The height of 2 is only limited to the passage of buckwheat, and the impurities are blocked by the baffle plate 2 to prevent them from enteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com