Atomization smashing device of medicine particles

A crushing device and granule technology, applied in grain processing, etc., can solve problems affecting the quality of drug intermediates, poor stability of intermediates, qualitative changes of drug granules, etc., to achieve good anti-blocking treatment, convenient feeding, and uniform material powder particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

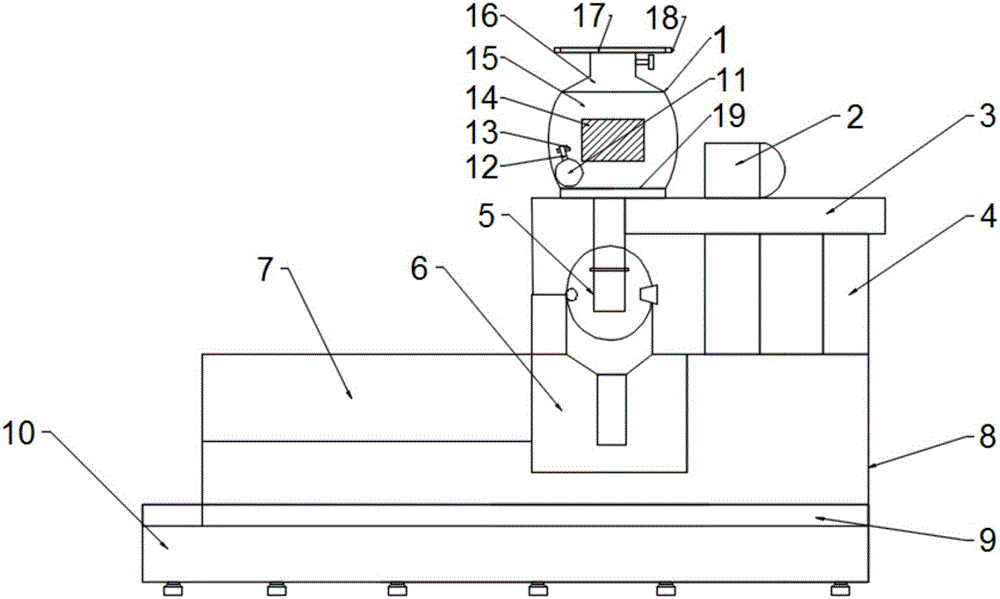

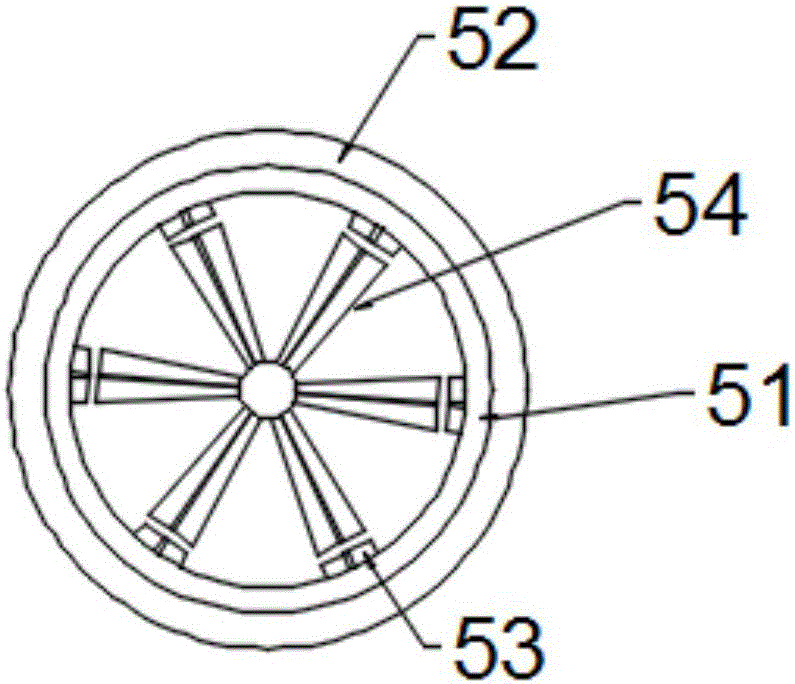

[0014] see Figure 1~2 , a mist pulverization device for medical particles, comprising an installation frame 10, and a feeder 1, a pulverizer 5, an atomizer group 4, a drying chamber 7 and a plate conveyor belt arranged on the installation frame 10; The feeder 1 communicates with the feeding end of the pulverizer 5, the pulverizer 5 includes a housing 51 and a motor connected to the pulverizer 5, and the inner wall of the housing 51 is provided with a fixed blade 53, and the center of the housing 51 There is a moving blade 54 matched with the fixed blade 53, and the moving blade 54 is connected to the motor;

[0015] The feeder includes a housing 15, a material inlet 16 and a material outlet arranged at the upper and lower ends of the housing 15, and the housing 15 is provided with an observation window 14 for observing the operation of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com