Microparticle anti-blocking type filling machine

A filling machine and micro-particle technology, which is applied in the field of micro-particle anti-blocking filling machines, can solve problems such as troublesome cleaning and control, powder flying up, and easy blocking of powder materials, etc. It is easy to observe, simple in structure, and easy to use. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

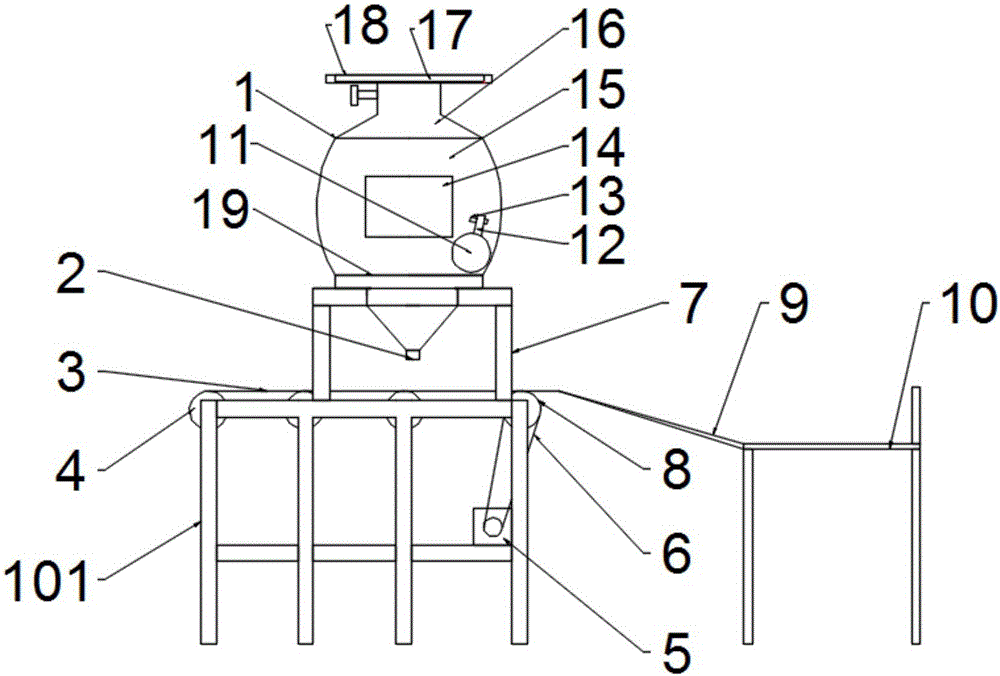

[0014] see figure 1 , a microparticle anti-blocking filling machine, including a conveying unit and a filling unit; the conveying unit includes a bracket 101, and a driving wheel 8 and three driven wheels 3 are arranged on the bracket 101; the driving wheel 8 and the slave The driving wheel 3 is provided with a conveyor belt 4, and the right side of the support 7 is provided with a discharge plate 9 and a packaging table 10; the bottom of the support 101 is provided with a motor 5; the motor 5 is connected with the driving wheel 8 through a hinge 6; The loading unit includes a workbench 7, and the workbench 7 is located on the top of the support 101; the top of the workbench 7 is provided with a feeder 1, and the lower end of the feeder 1 is connected with a discharge port 2, and a discharge port is provided at the discharge port. Electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com