S-shaped spring extrusion punching die

A technology of shaped springs and punching dies, which is applied in the field of S-shaped spring extrusion punching dies, can solve the problems of unfavorable enterprise competitive advantage, poor applicability, and increased shearing steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

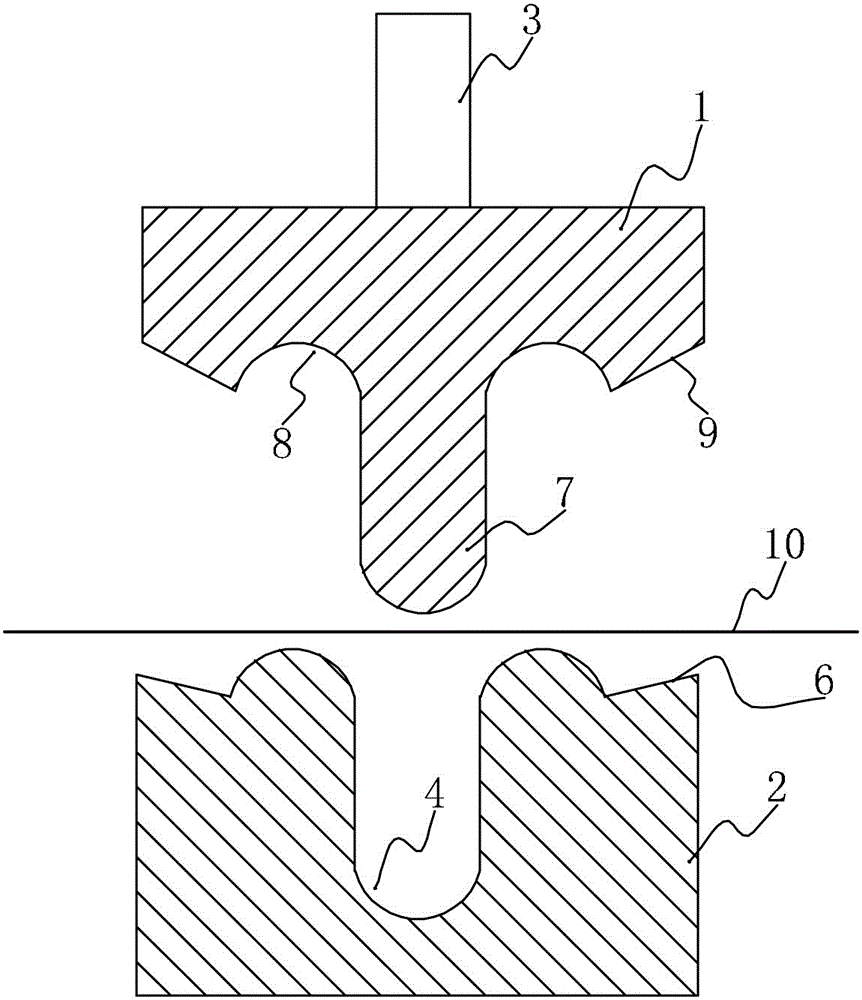

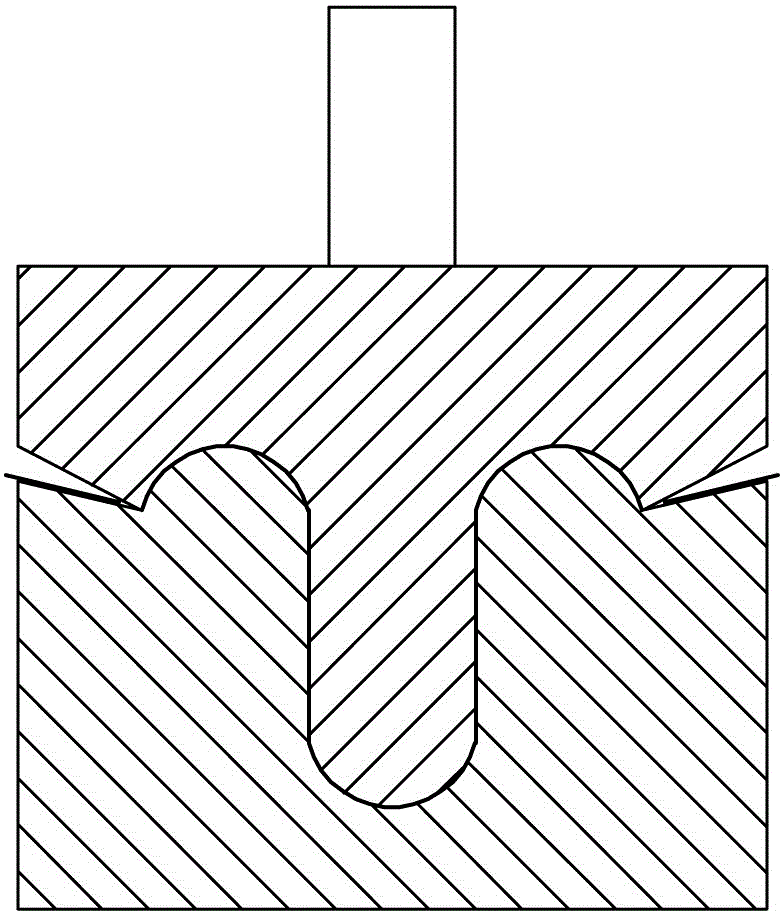

[0016] Such as figure 1 As shown, the S-shaped spring extrusion punching die of the present invention includes an upper die 1 and a lower die 2 used in conjunction. The upper mold 1 is a movable mold that can be driven to move up and down by the upper mold handle 3. Lower mold 2 is fixed mold, is fixed on the base and cannot move. A bending cavity is opened in the lower die 2, a U-shaped deep groove 4 is formed in the bending cavity, and the bottom of the deep groove 4 is arc-shaped. Two arc-shaped protrusions 5 are symmetrically arranged on both sides of the deep groove 4 in the bending cavity, and a lower shear portion is formed on the outer side of the protrusion 5, and the lower shear portion has an inclined lower shear edge 6, The intersection of the lower shearing edge 6 and the protrusion 5 forms a shearing opening. A downward bending portion is formed on the upper mold 1 , and a U-shaped protrusion 7 is formed in the bending portion, and the protrusion 7 can be inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com