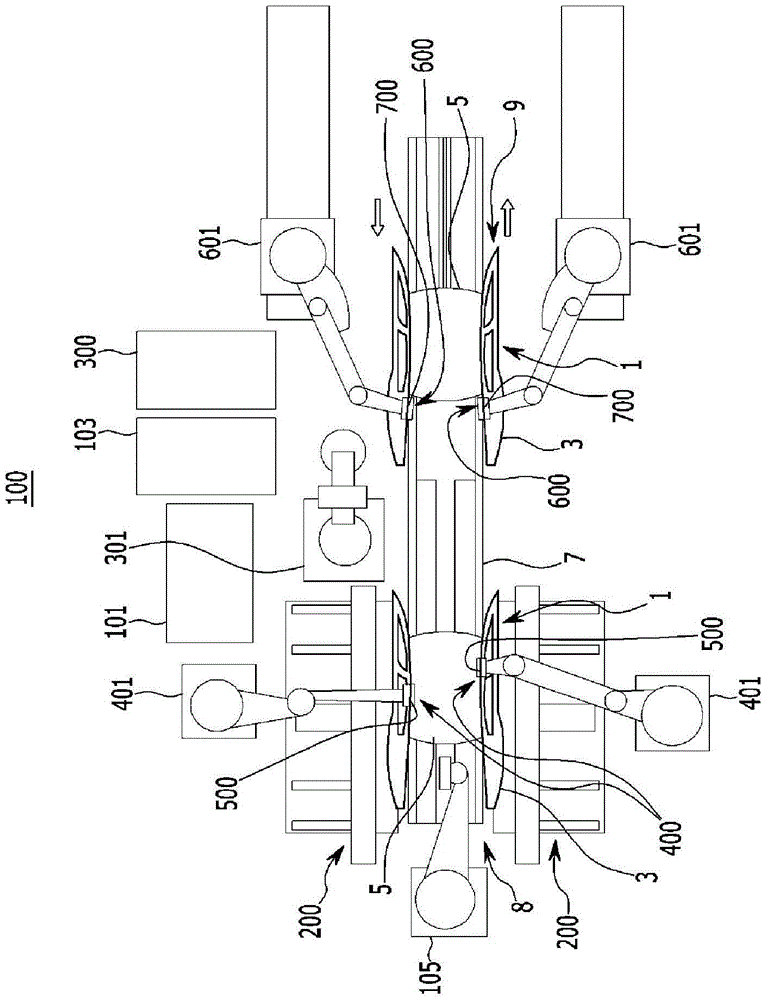

Brazing assembly for roof laser-brazing system

A brazing and assembly technology, applied in vehicle parts, welding equipment, auxiliary welding equipment, etc., can solve the problems of increased material cost and personnel cost, unpleasant and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

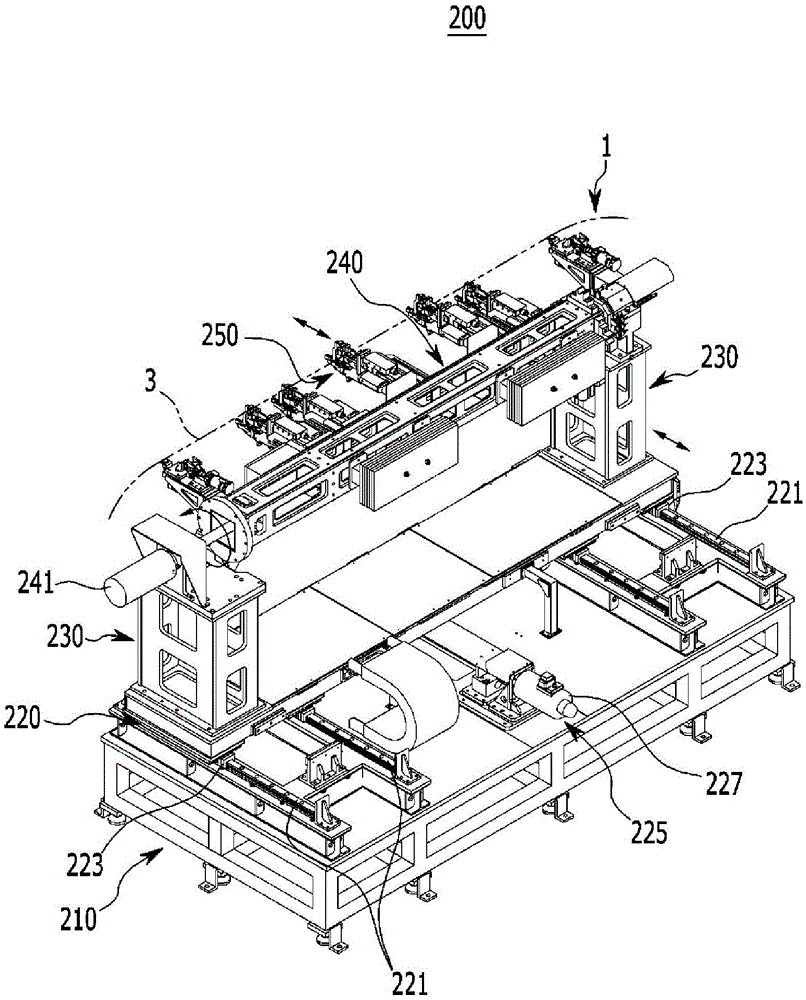

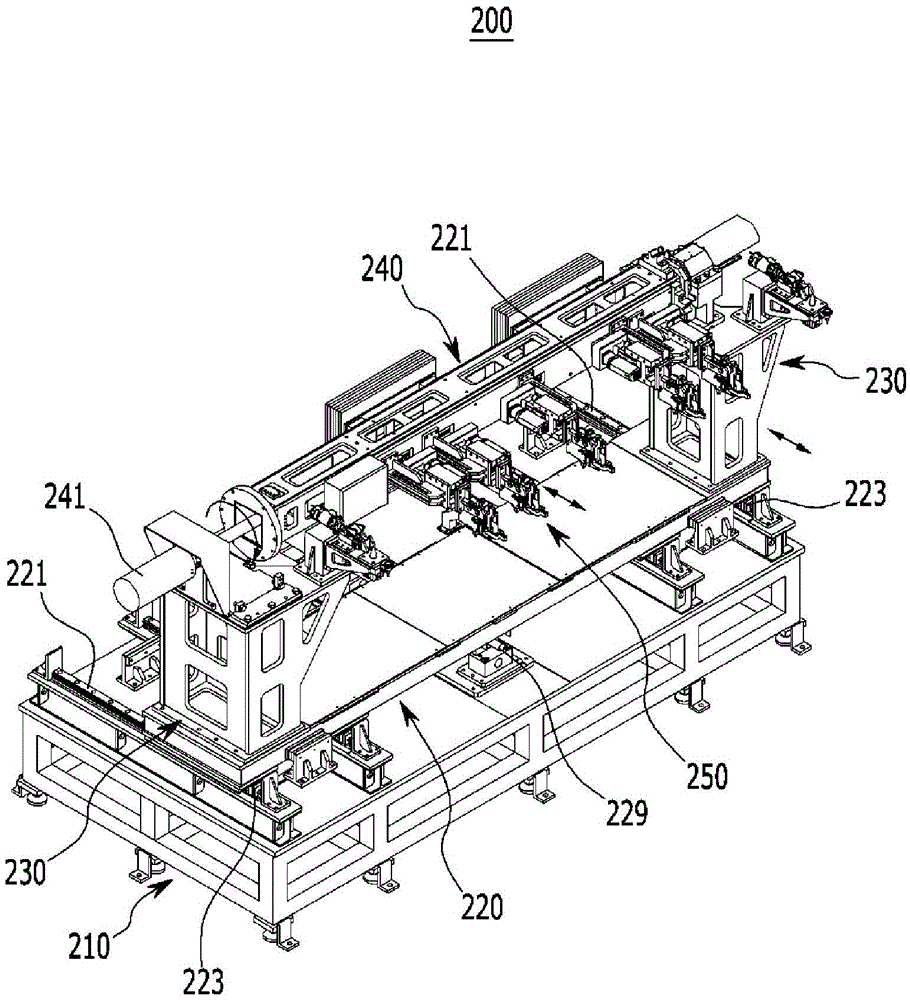

[0090] Hereinafter, the present disclosure will be described more fully with reference to the accompanying drawings, in which exemplary forms of the disclosure are shown. As those skilled in the art would realize, the described forms may be modified in various different ways, all without departing from the spirit or scope of the present disclosure.

[0091] In order to clearly describe the present disclosure, parts irrelevant to the description will be omitted. Throughout this specification, the same reference numerals refer to the same elements.

[0092] Since sizes and thicknesses of respective components are arbitrarily shown in the drawings for convenience of explanation, the present disclosure is not limited to what is shown in the drawings. Also, the thickness may be exaggerated in order to clearly present various parts and regions.

[0093] In the following detailed description, the same components are classified as "first", "second", etc. to distinguish the names of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com