Grinding machine used for machining automobile die

A technology for automobile molds and grinding machines, which is applied in the direction of grinding machines, manufacturing tools, and grinding beds, etc., which can solve the problems of poor operating environment, low processing accuracy, and easy damage, and achieve long service life, high processing accuracy, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

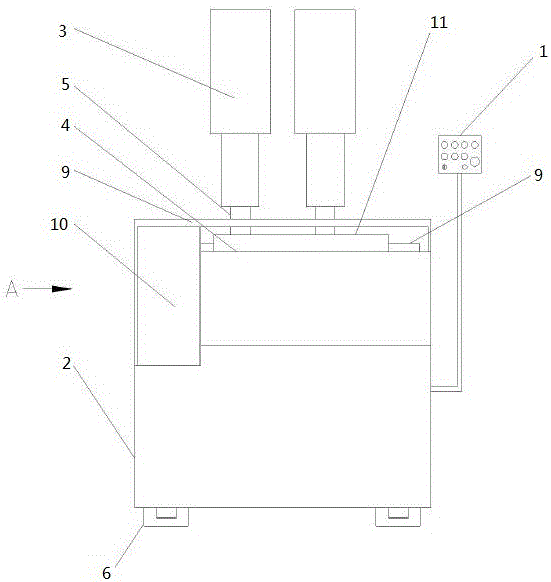

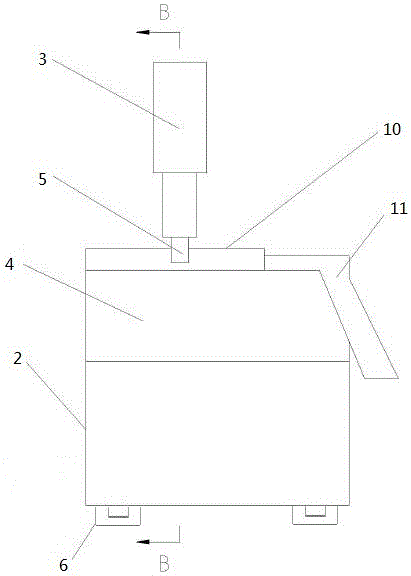

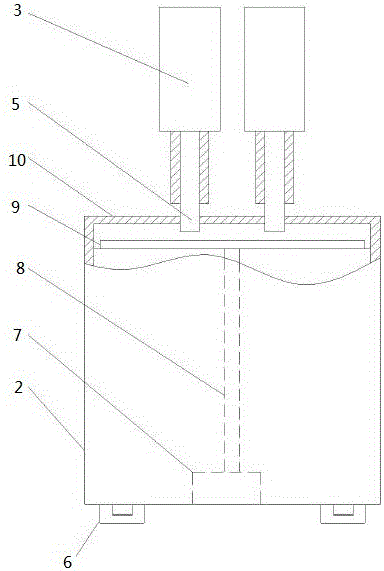

[0018] Such as figure 1 , figure 2 , image 3 As shown, a grinding machine for processing automobile molds includes a grinding machine base 2 connected with an electric control box 1, a grinding motor 3 and a workbench 4 are fixedly arranged on the grinding machine base 2, and the bottom of the grinding machine base 2 is provided with An anti-vibration mechanism 6; the grinding motor 3 is connected with a grinding head 5, and the grinding head 5 is arranged above the workbench 4; a speed-regulating motor 7 is also arranged in the grinding machine base 2, and the speed-regulating motor 7 passes through a transmission The shaft 8 is connected with an electromagnetic chuck 9; the electromagnetic chuck 9 is arranged on the workbench 4, and the electromagnetic chuck 9 is disc-shaped; as Figure 4 As shown, the electromagnetic chuck 9 includes a chuck body 91, and the chuck body 91 is equally divided into a fan-shaped part 93 by a groove 92; the coils distributed in the fan-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com