Automatic packing control system based on assembly line

A technology of automatic packing and control system, applied in the direction of automatic packaging control, packaging, packaging protection, etc., to achieve the effect of reducing hidden dangers, preventing product damage, and ingenious mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

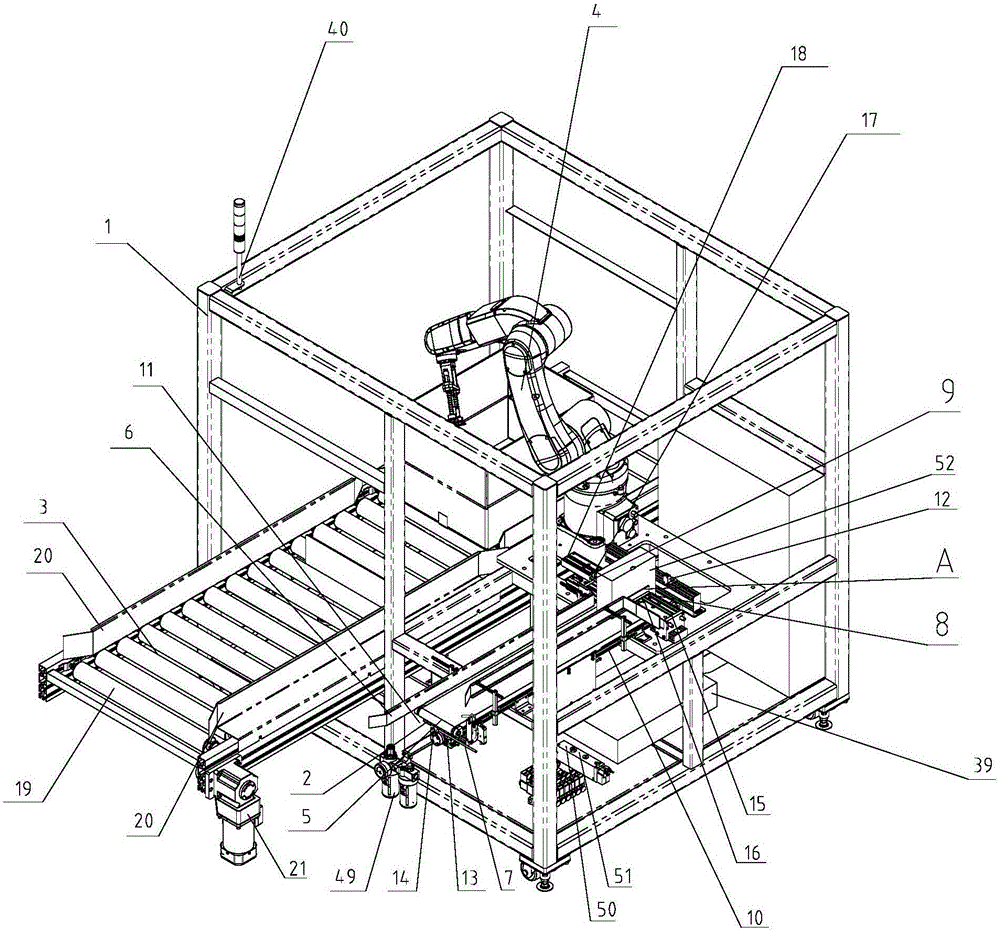

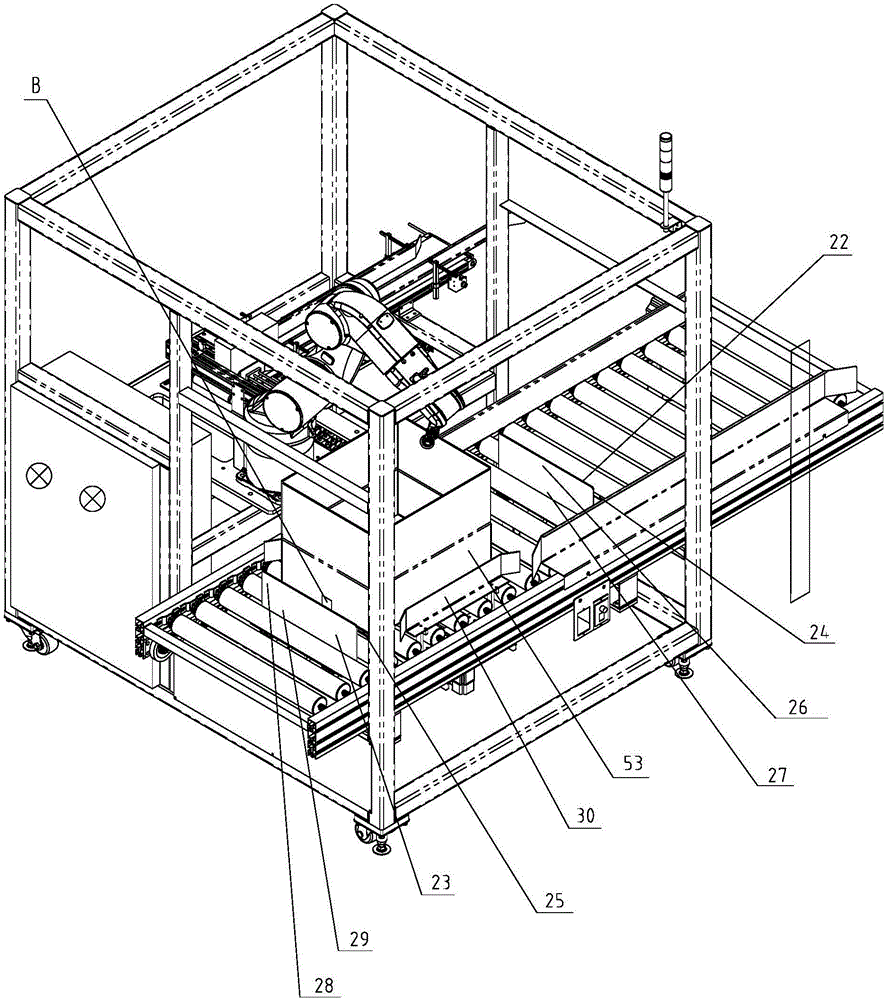

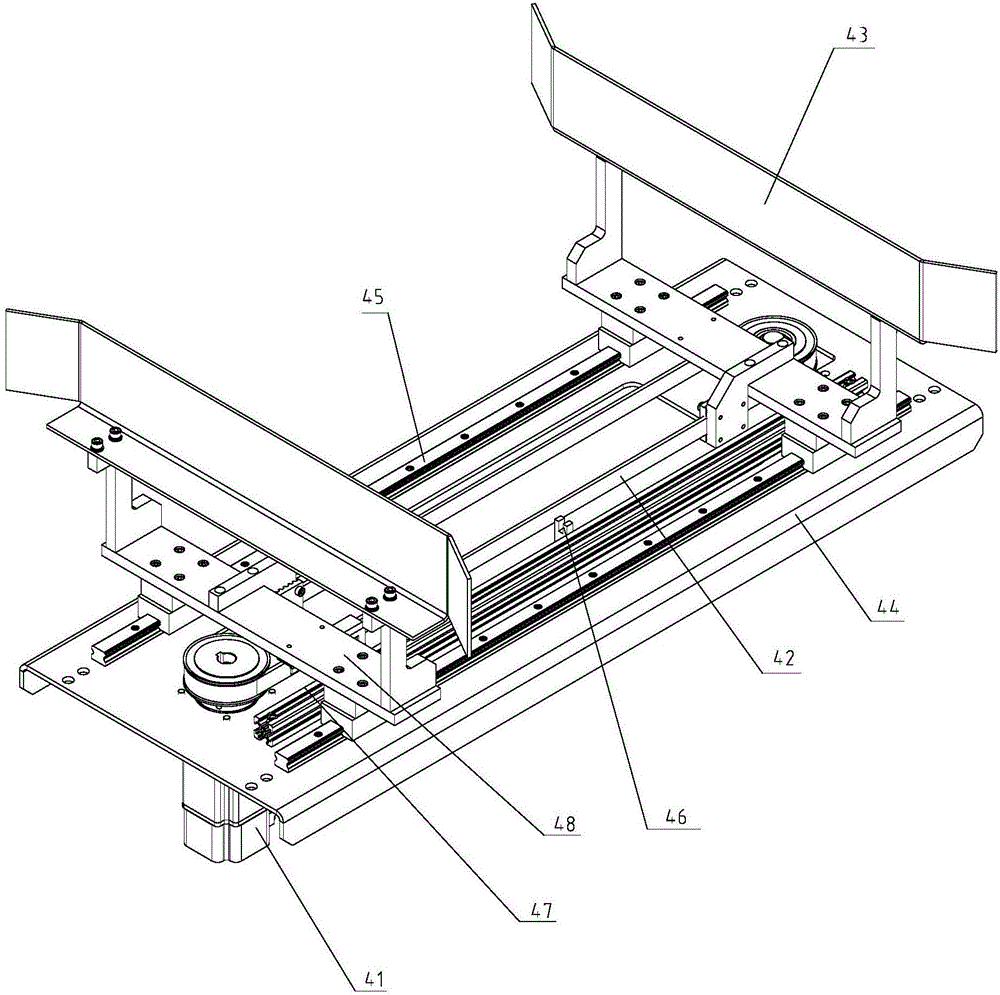

[0027] Such as Figure 1 ~ Figure 4As shown, an automatic packing control system based on an assembly line, including a frame body 1, a carton transmission positioning mechanism 2, a carton transmission positioning mechanism 3, a robot body 4, a PLC controller, a robot controller 39, and a touch screen; The carton transmission positioning mechanism 2 includes a conveying belt 5, a carton guide plate 6, a push rod 7, a carton positioning assembly 8 and a follower assembly 9, the conveying belt 5 is arranged on the frame body 1, and the conveying At least one side of the belt 5 is provided with a carton guide plate 6, a first conveying motor 10 for driving the conveying belt 5 is arranged below the conveying belt 5, a first sensor 11 is provided at the head end of the conveying belt 5, and the conveying belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com