A kind of production method of sterilized condom

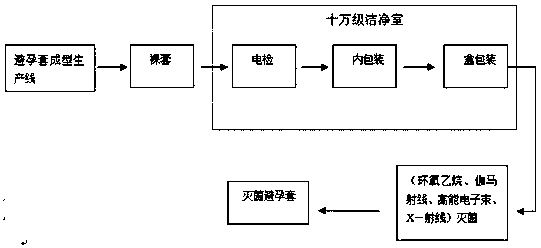

A production method and condom technology, applied to the production of ethylene oxide gaseous fungicide or radiation for sterilization, in the field of sterilized condoms, which can solve the problems of exacerbation of the disease, the failure of the condom to reach its function, and easy breeding. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The composite film of PE and PVC is selected as the inner packaging material of the condom, among which: the PE layer is in direct contact with the condom; PVC is the outer printing layer, and the production batch number and expiration date can also be hot stamped as required. Because the PE film is relatively soft and has good extensibility, when it is used as a condom package, a PE film with a thickness of 0.08mm is used for separation and protection; in addition, a hard PVC film with a thickness of 0.15mm is used to support and protect the entire package. Decorative effect. The inner packaging of the condom must comply with the principle of easy access during use. Therefore, when packaging the condom, press the hand-tear line (or laser-cut hand-tear line) on the seal of the package, and cooperate with the sawtooth on the traditional packaging. Easy to tear apart and use.

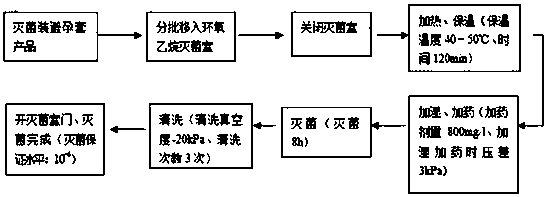

[0027] Since ethylene oxide has different penetrating power to various superimposed materials,...

Embodiment 2

[0036] The composite film of PE and PVC is selected as the inner packaging material of the condom, among which: the PE layer is in direct contact with the condom; PVC is the outer printing layer, and the production batch number and expiration date can also be hot stamped as required. Because the PE film is relatively soft and has good extensibility, when it is used as a condom package, a PE film with a thickness of 0.08mm is used for separation and protection; in addition, a hard PVC film with a thickness of 0.15mm is used to support and protect the entire package. Decorative effect. The inner packaging of the condom must comply with the principle of easy access during use. Therefore, when packaging the condom, press the hand-tear line (or laser-cut hand-tear line) on the seal of the package, and cooperate with the sawtooth on the traditional packaging. Easy to tear apart and use.

[0037] Since ethylene oxide has different penetrating power to various superimposed materials,...

Embodiment 3

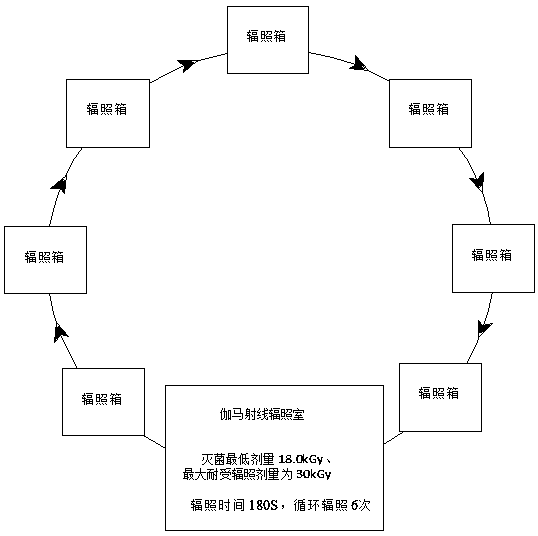

[0046] Sterilization by gamma ray: First, the number of initial contamination bacteria of the condom is detected, and the minimum sterilization dose is determined and verified. According to the requirements of the irradiation box for the condom packaging size, the packaging outer box size of this method is 705*305*440mm, and the minimum sterilization dose is finally determined to be 18.0kGy, and the maximum tolerated radiation dose is 30.0kGy. The condoms that need to be sterilized are sent into the irradiation box together with the packaging, the irradiation time is set to 180S, and the irradiation process is 6 times to complete the sterilization of the condom product, and the sterilization guarantee level is 10 -6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com