Special spiral grid decontaminating equipment for large material treatment

A grille decontamination and spiral technology, which is used in filtration treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult cleaning and high failure rate, and achieve the effect of increasing the failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

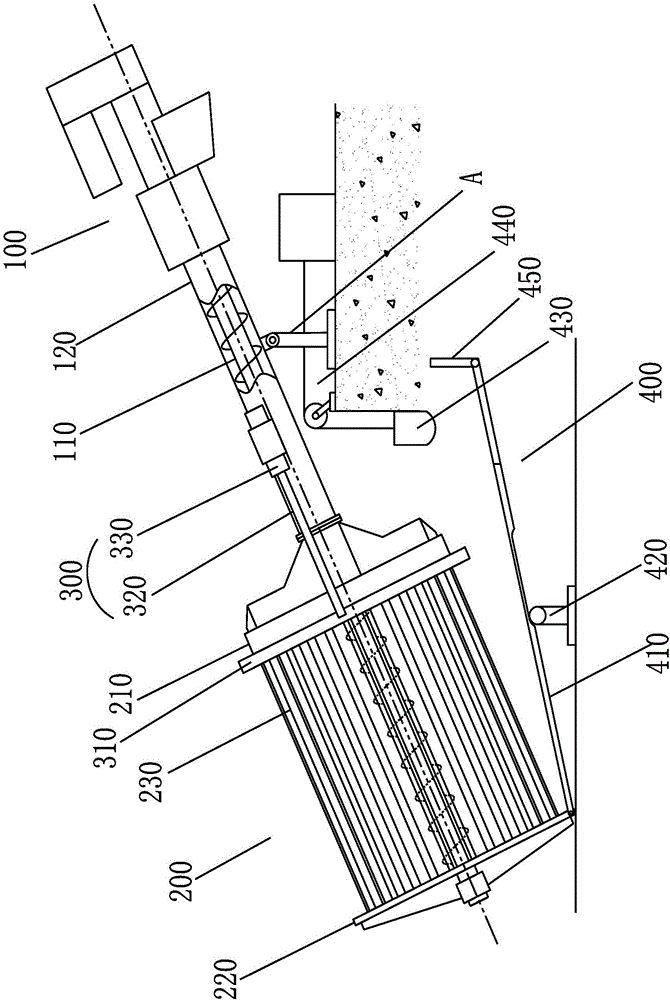

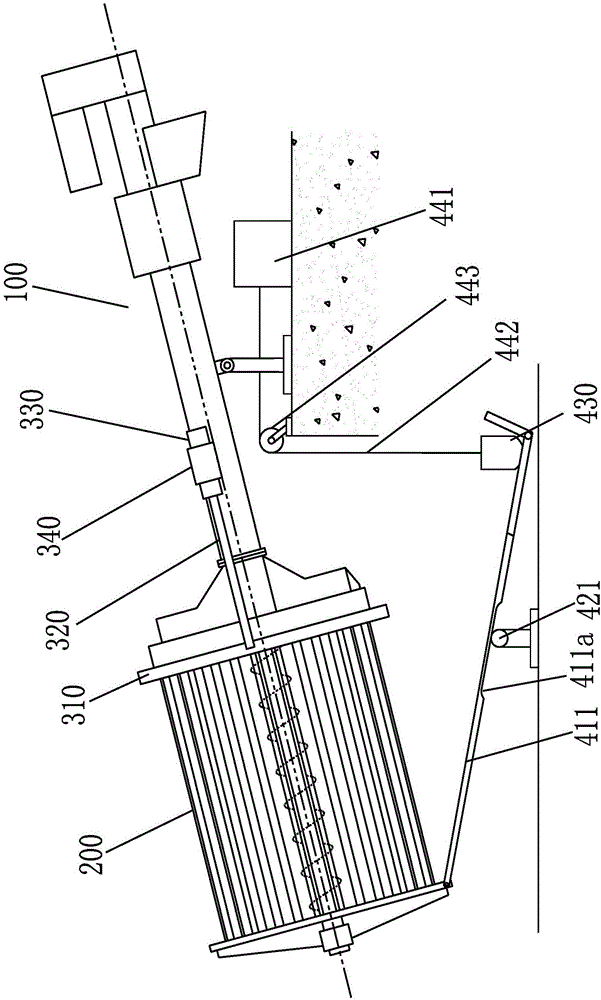

[0020] refer to Figure 1-2 shown and combined with Figure 3-4 , the present invention proposes a spiral grid decontamination equipment dedicated to the treatment of coarse objects, including a screw conveyor assembly 100 and a grid filter assembly 200, the screw conveyor assembly 100 includes a screw conveyor 110 driven by a deceleration motor, and at the same time It further includes a scraper assembly 300 arranged on the grid filter assembly 200 and a jacking assembly 400 connected to the grid filter assembly 200;

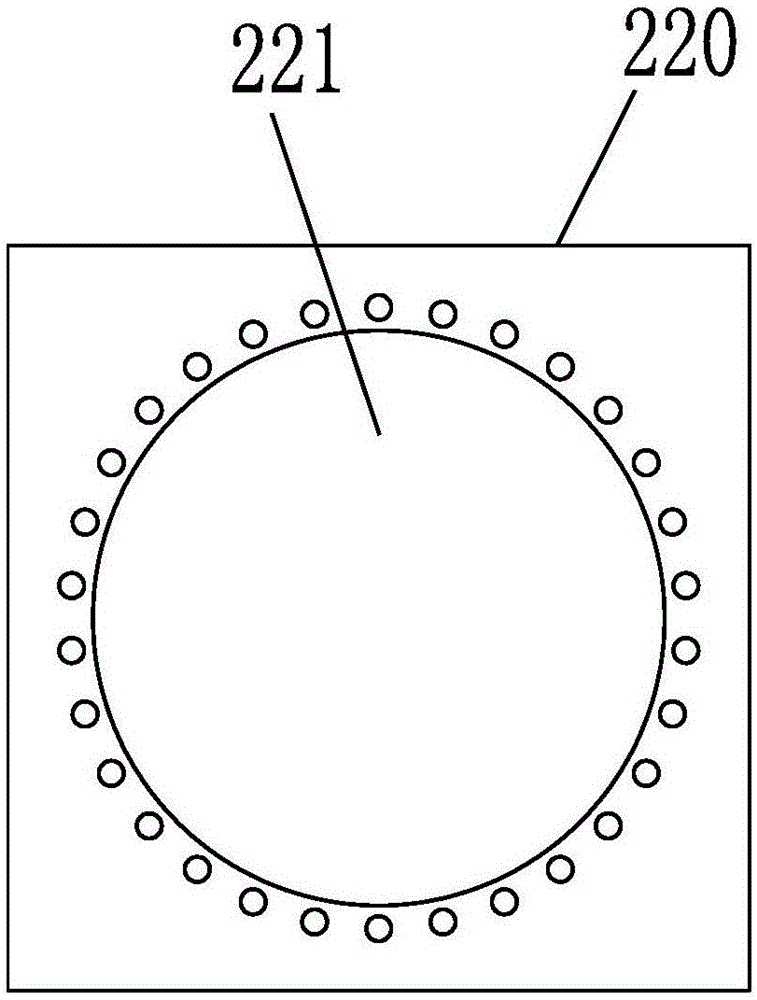

[0021] Wherein, the grid filter assembly 200 includes an upper end plate 210, a lower end plate 220 and a plurality of grid bars 230, and the plurality of grid bars 230 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com