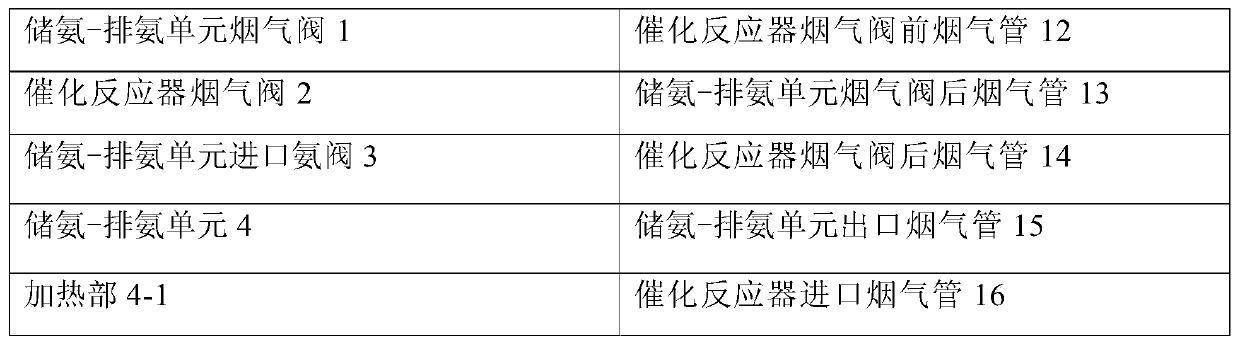

Patents

Literature

36results about How to "Improve failure rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

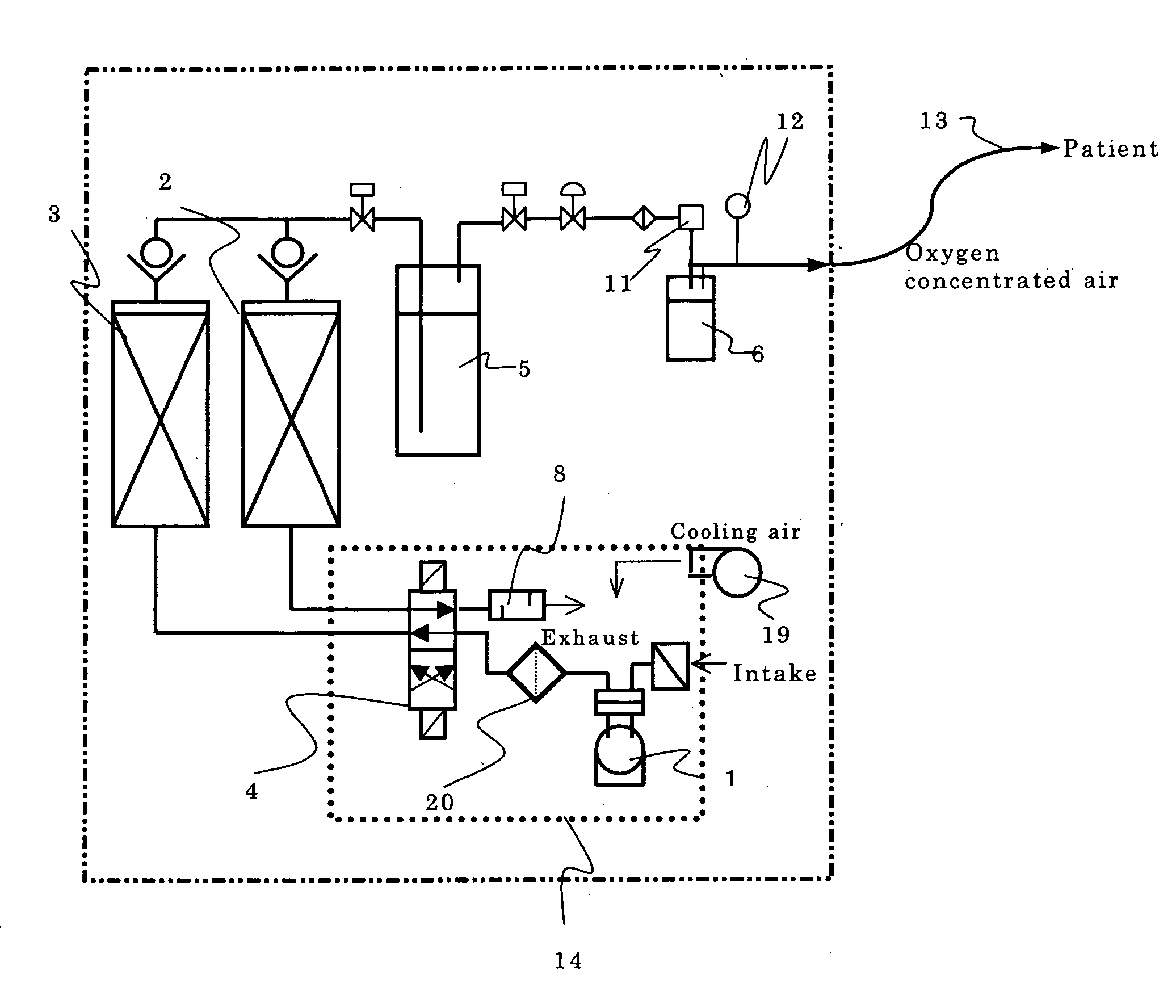

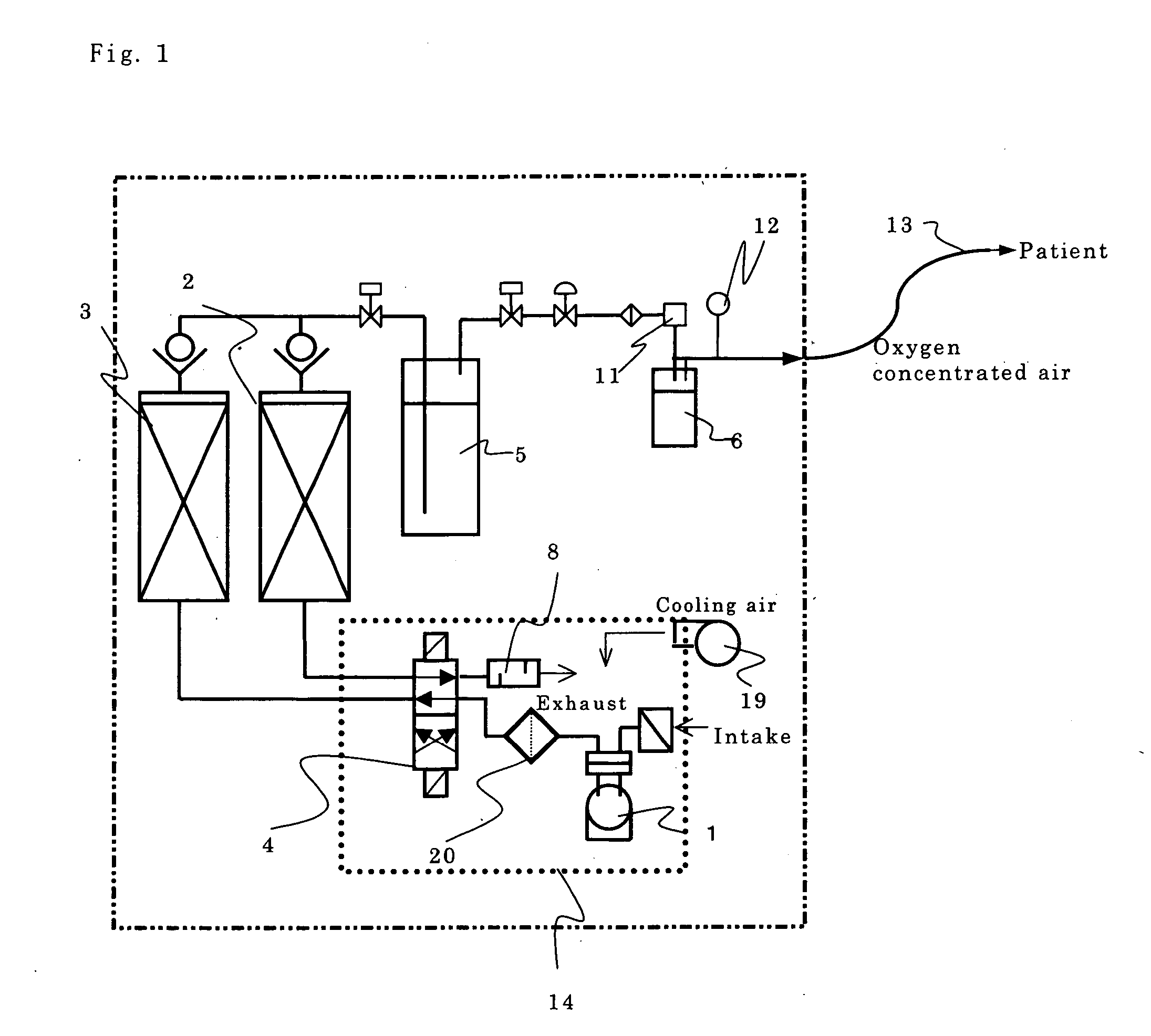

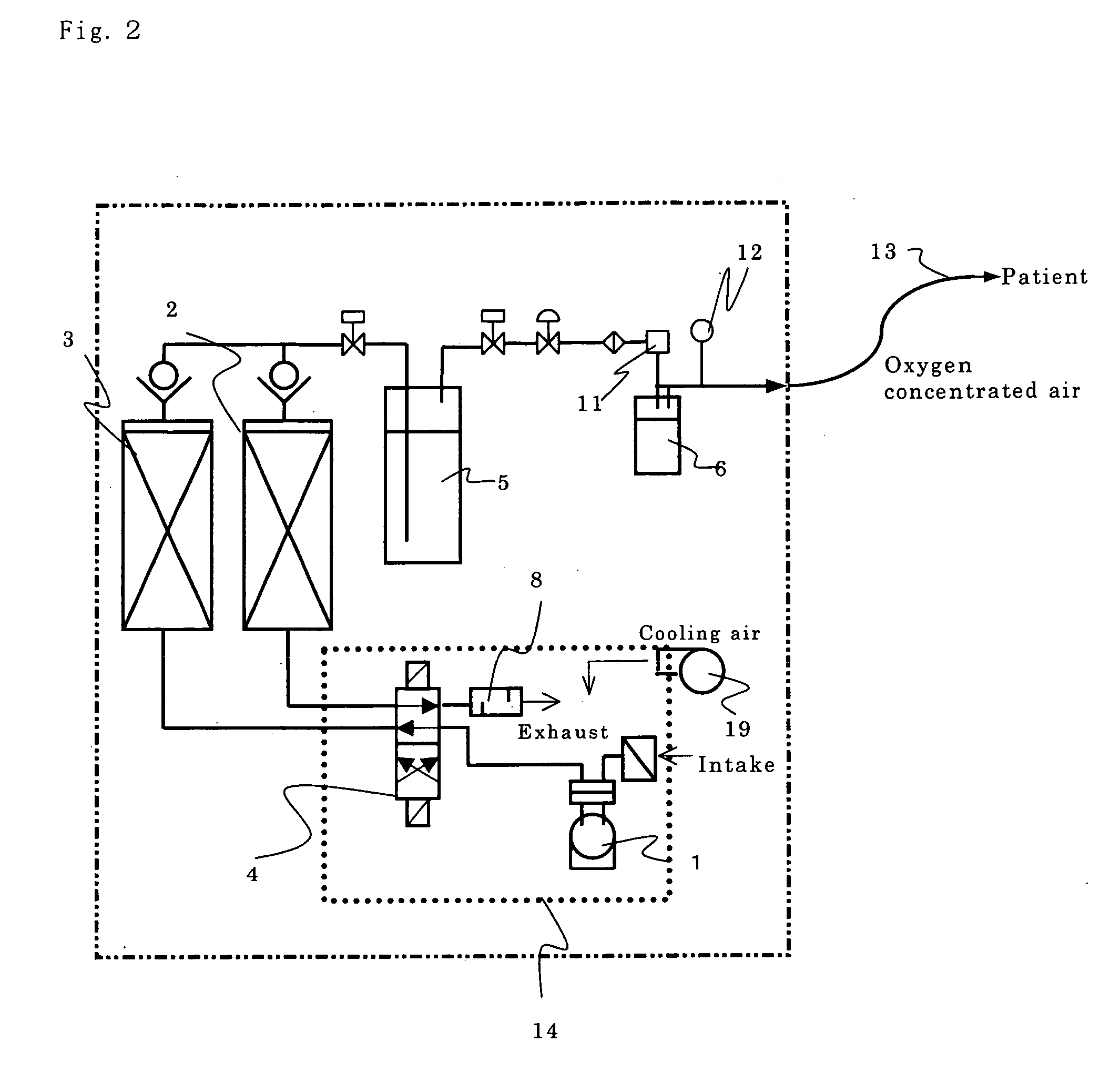

Oxygen concentrator for medical treatment

InactiveUS20060137522A1Avoid vibrationLow rate of occurrenceRespiratorsGas treatmentWear particleNitrogen

The present invention provides, as a pressure swing adsorption type oxygen concentrator aiming to be used for the home oxygen therapy, and having the device reliability ensuring a low failure occurrence rate, and the adsorption performance stability, ensuring the stable oxygen concentration performance even over a long period, a pressure swing type oxygen concentrator having at least one adsorption column charged with an adsorbent capable of preferentially adsorbing nitrogen rather than oxygen, and an air compressor for pressure supplying and / or vacuum exhausting air to and / or from the adsorption column, characterized by including a nonwoven fabric filter for collecting sealing material wear particles in an air channel between the adsorption column and the air compressor.

Owner:TEIJIN PHARMA CO LTD

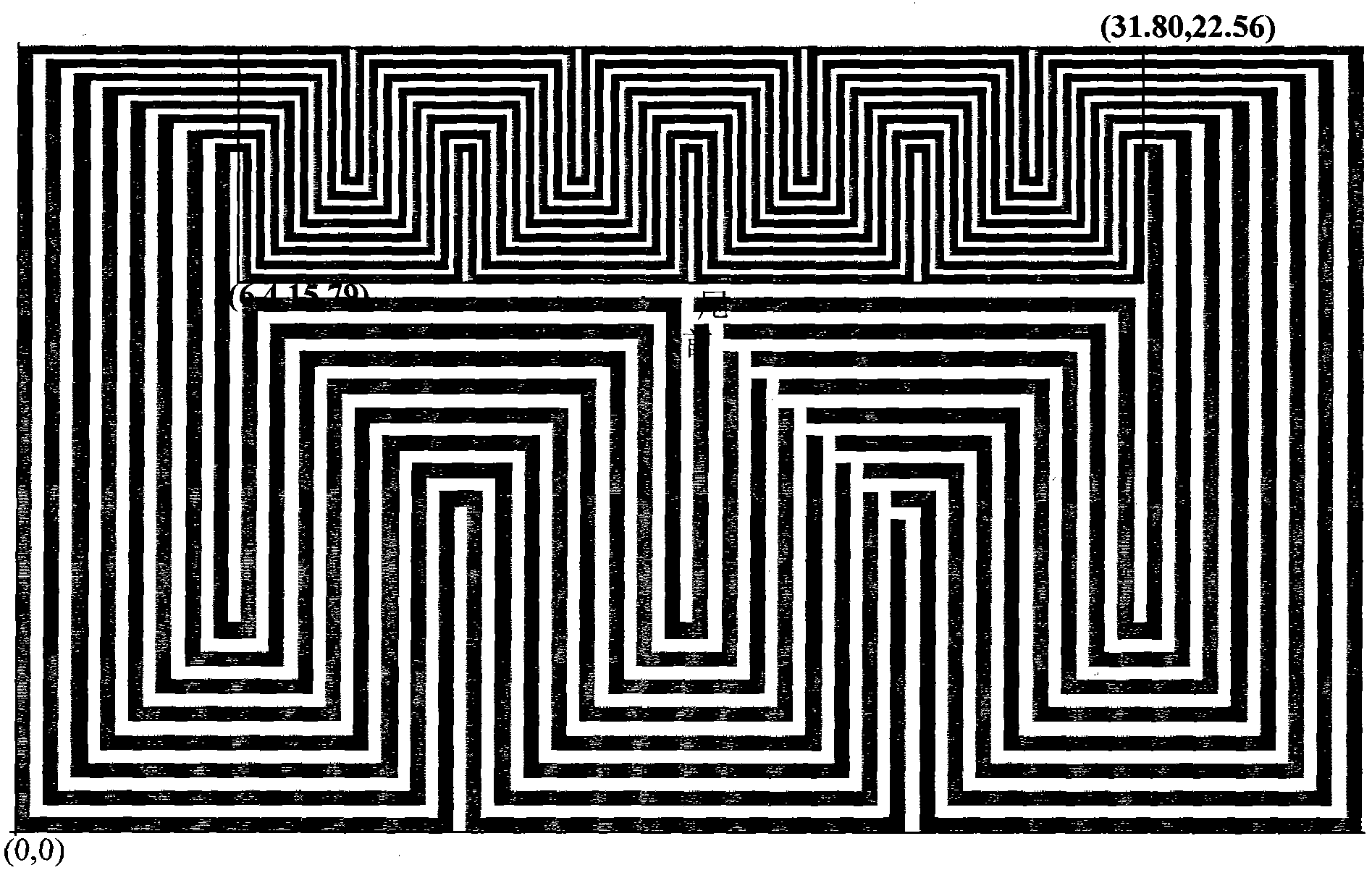

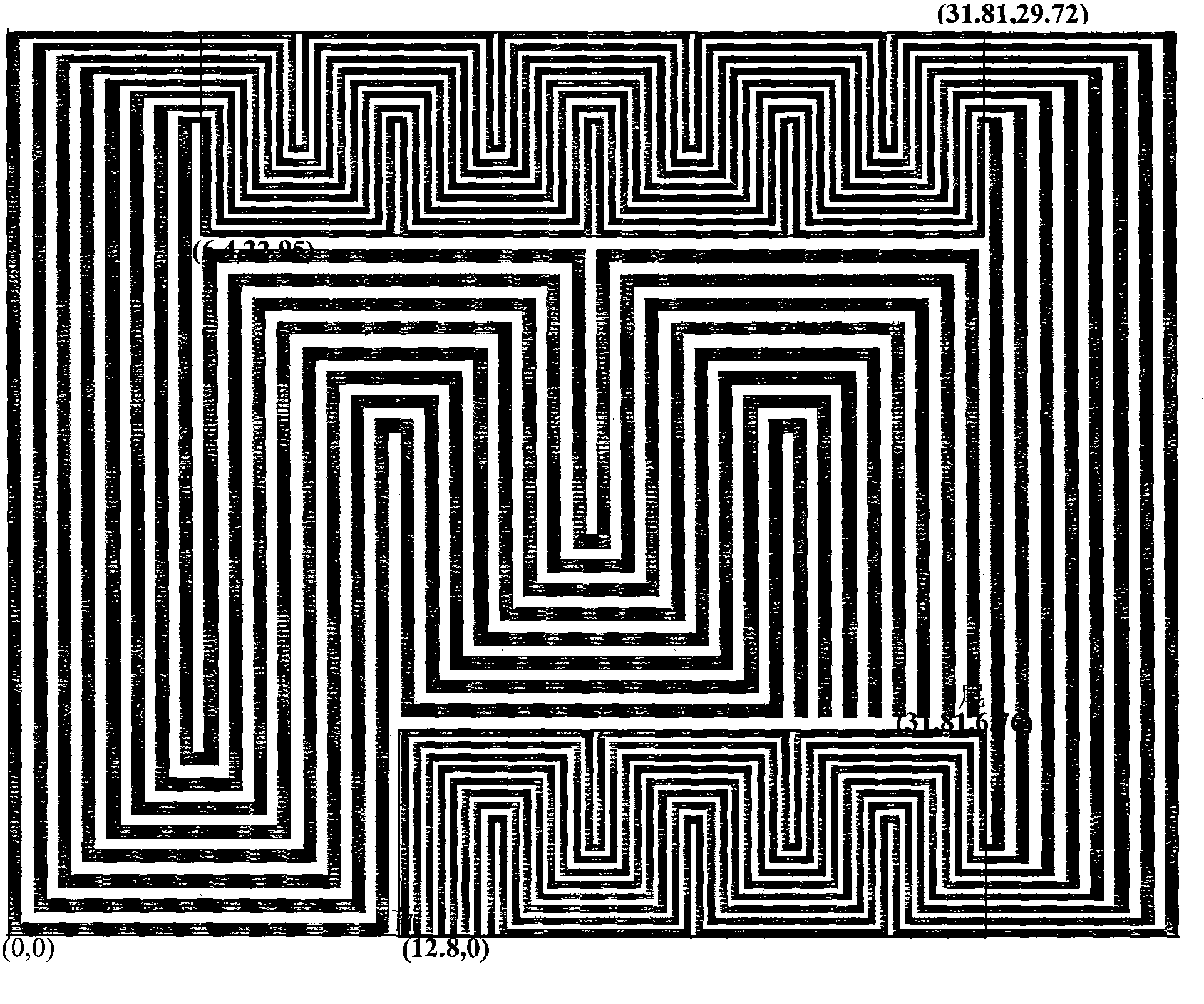

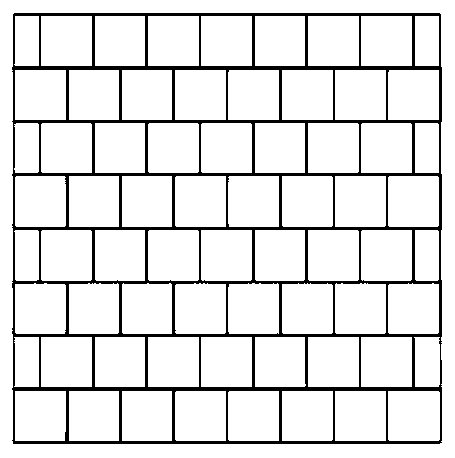

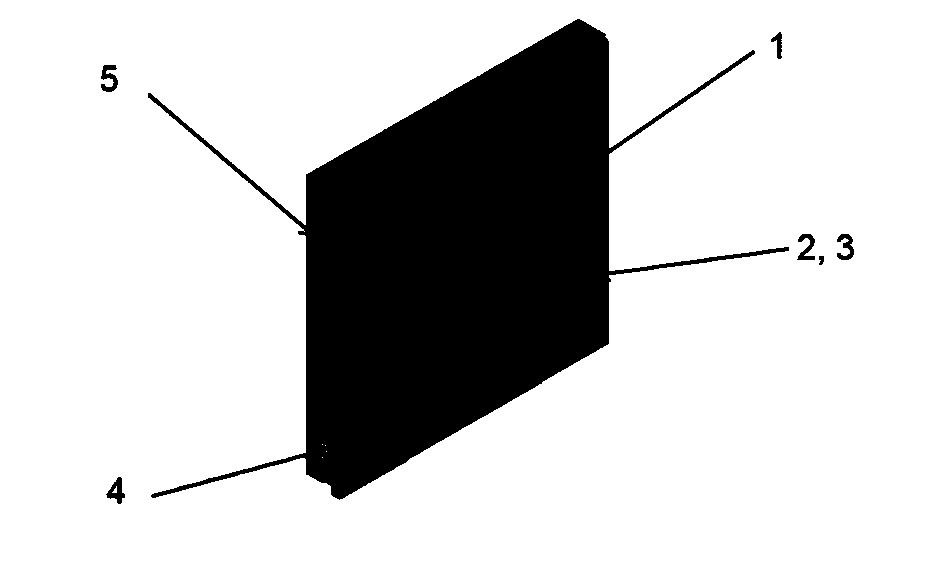

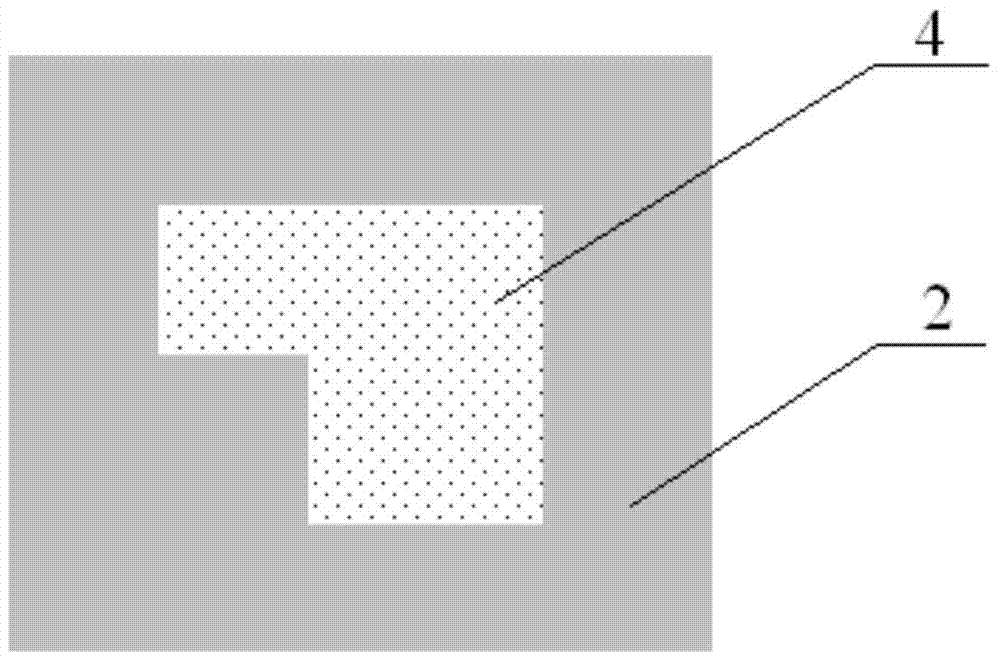

Method for designing high-safety chip active shielding physical protection structure

InactiveCN103646137AImprove failure rateReduce failure rateSpecial data processing applicationsEngineeringFailure causes

The invention provides a method for designing a high-safety chip active shielding physical protection structure. The chip active physical protection structure has the function that a high-safety chip is prevented from being attacked in an intrusive mode, for example the high-safety chip is tampered or detected in a physical mode. Single-layer metal wires are active shielding wires and the active shielding wires are fully distributed on the surface of the chip. In order to protect a lower-layer physical pattern against attack, the smallest design rule is usually adopted by the metal wires. If patterns designed according to the smallest rule are fully distributed on the chip, the possibility that the chip circuit functional performance failure caused by particle contamination is increased. In order to reduce the volume production chip circuit failure, the width and / or the spacing of the active shielding wires are / is usually widened. If the size of each active shielding wire is widened, the safety of the chip can be reduced. In order to solve the problem of the contradiction between the safety of the chip and the yield of the volume production products, the pitch-variable active shielding physical production structure is further provided, so that dual-improvement in the safety and the yield of the chip products is achieved.

Owner:BEIJING CEC HUADA ELECTRONIC DESIGN CO LTD

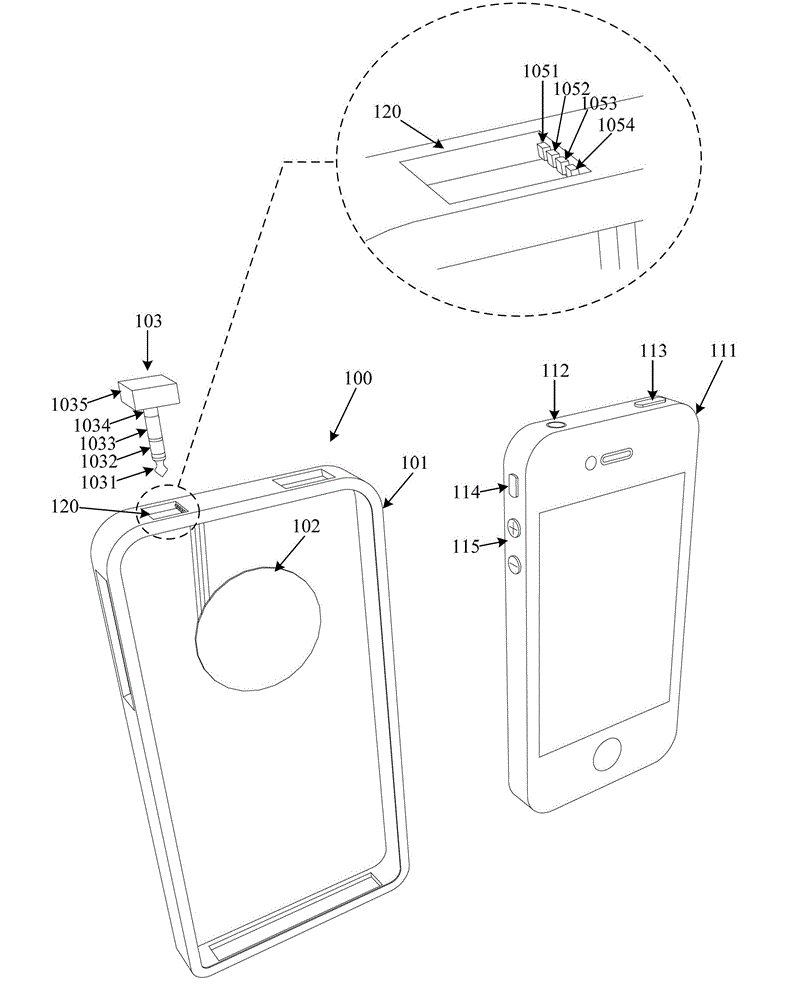

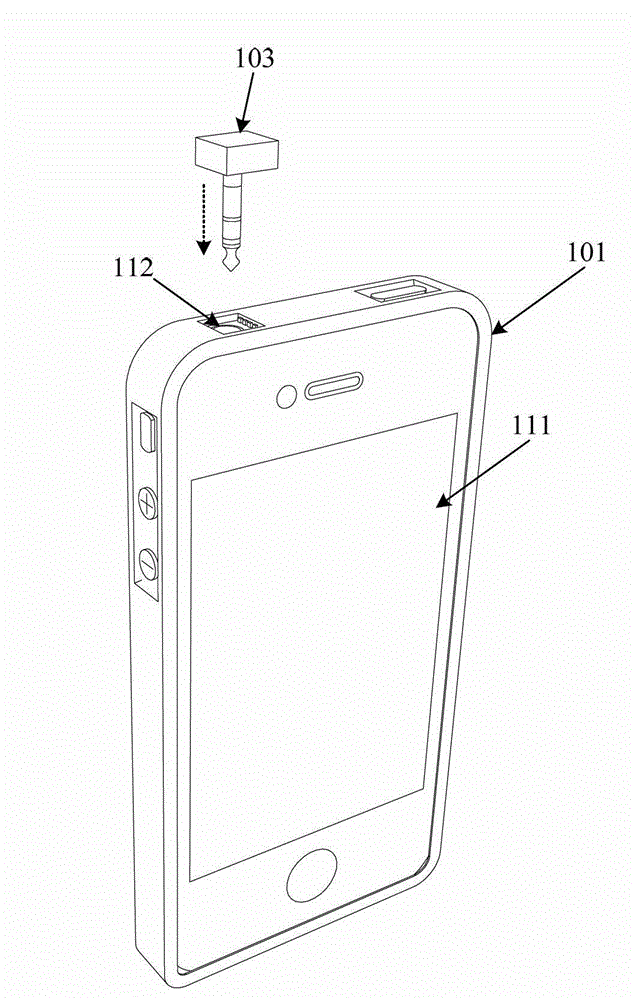

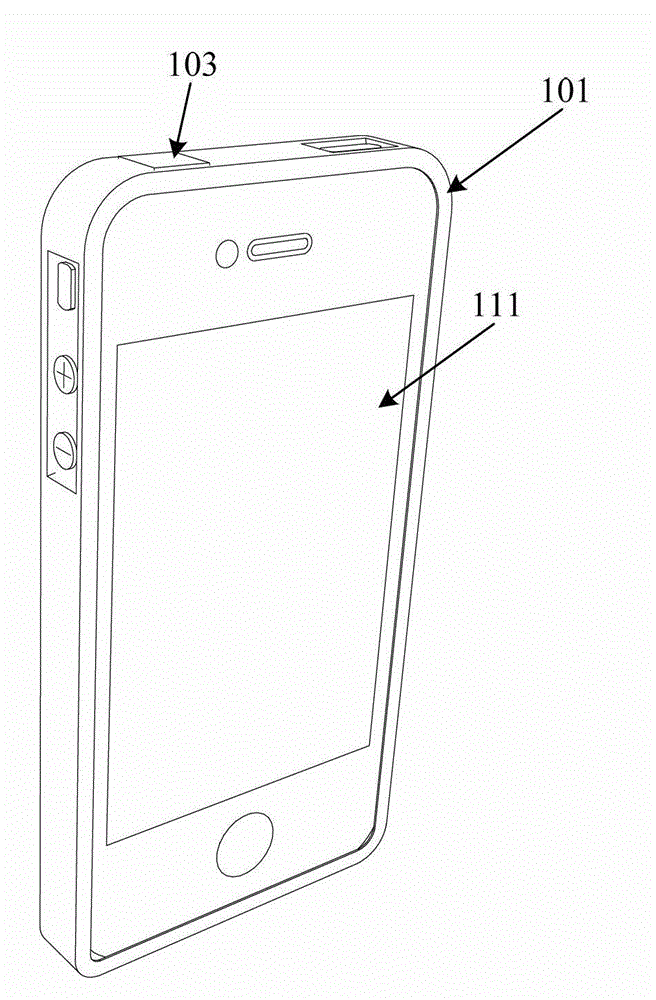

Jacket device of portable data processing equipment

InactiveCN103142010AReduce the difficulty of operationEasy to operateOther accessoriesTelephone set constructionsData acquisitionInformation device

The application discloses a jacket device of portable data processing equipment. The jacket device comprises a jacket shell, an information device and a signal plug, wherein the structure of the jacket shell is matched with the shell of the portable data processing equipment and the jacket shell can be sheathed at the external part of the portable data processing equipment; the information device is integrated on the jacket shell and is used for acquiring and / or outputting information; the signal plug and the jacket shell are of an integral structure or split structure, the signal plug is correspondingly matched with a first signal jack in the portable data processing equipment and can be inserted into the first signal jack; if the signal plug and the jacket shell are of the integral structure, the electrode of the signal plug is connected with the signal line of the information device on the jacket shell; and if the signal plug and the jacket shell are of the split structure, when the signal plug is inserted into the first signal jack, the electrode of the signal plug is in contact with the signal line of the information device. By using the jacket device, the complexity of data acquisition of the portable data processing equipment can be reduced.

Owner:理康互联科技(北京)有限公司

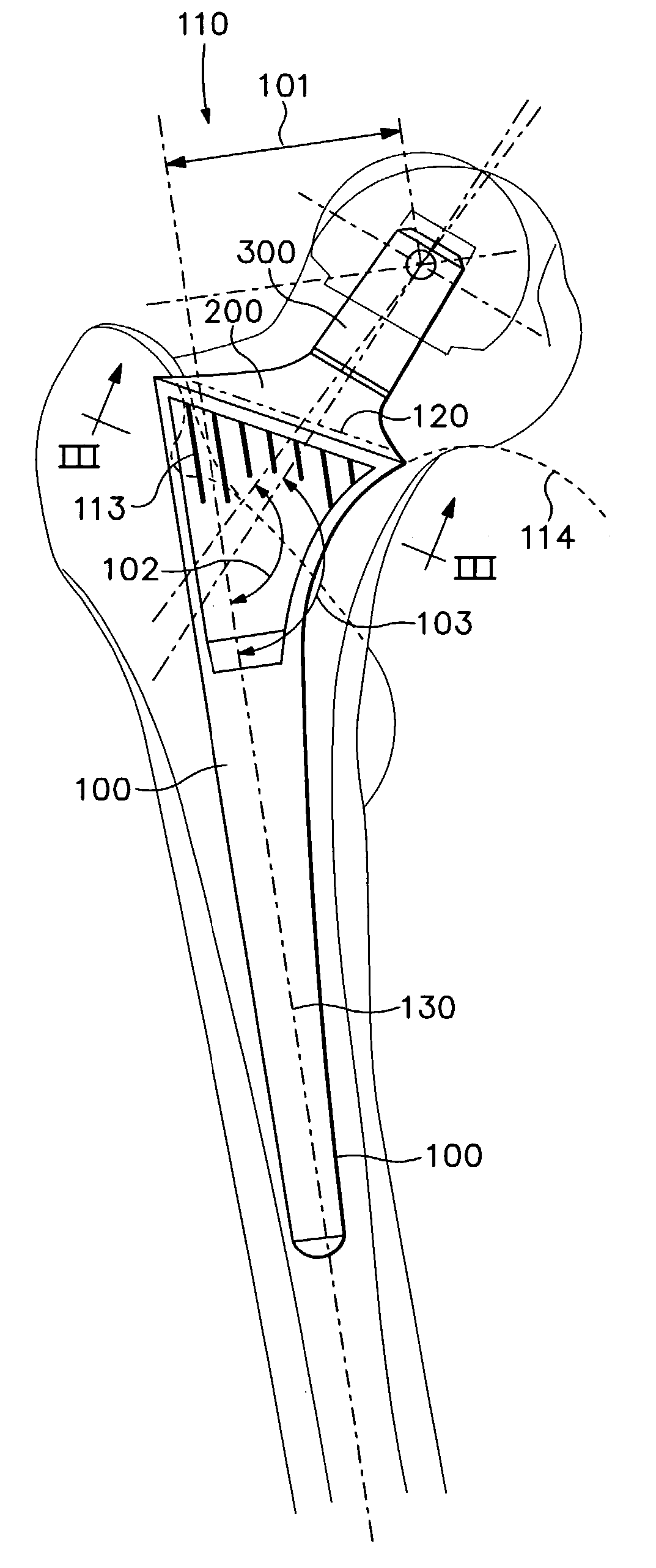

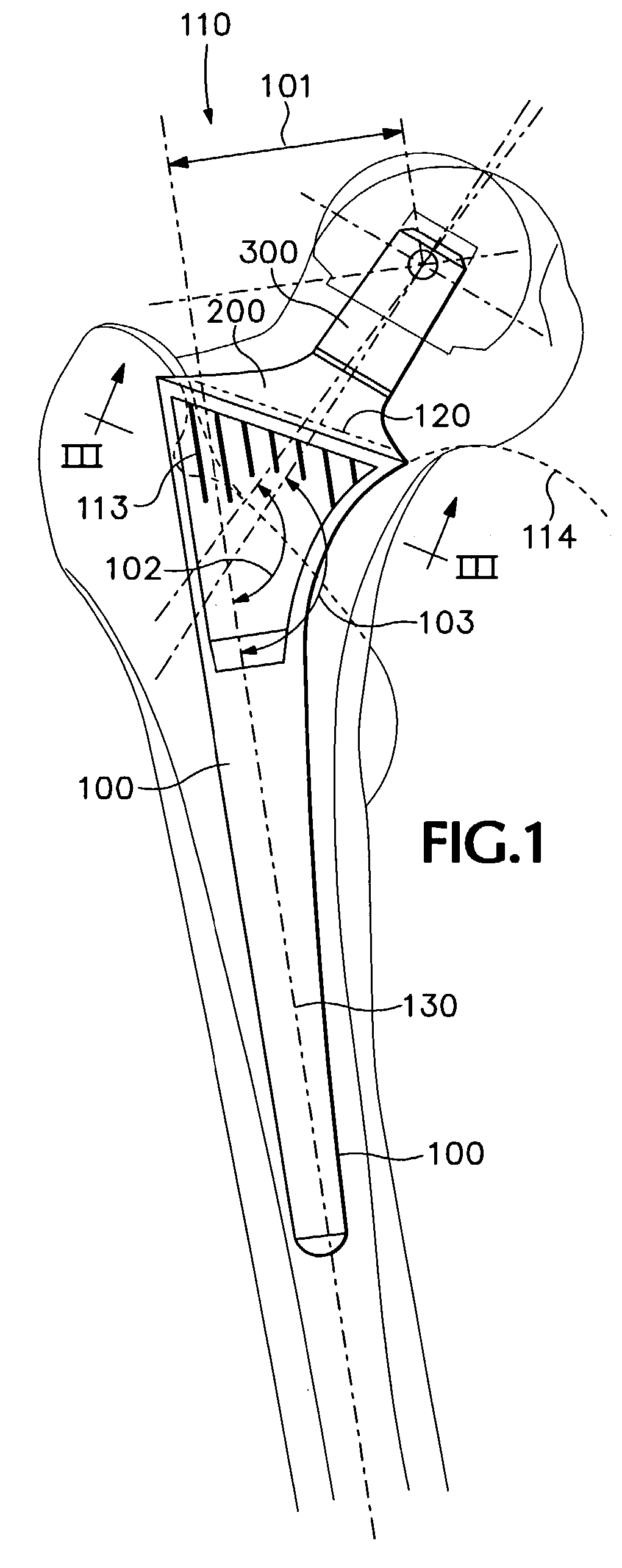

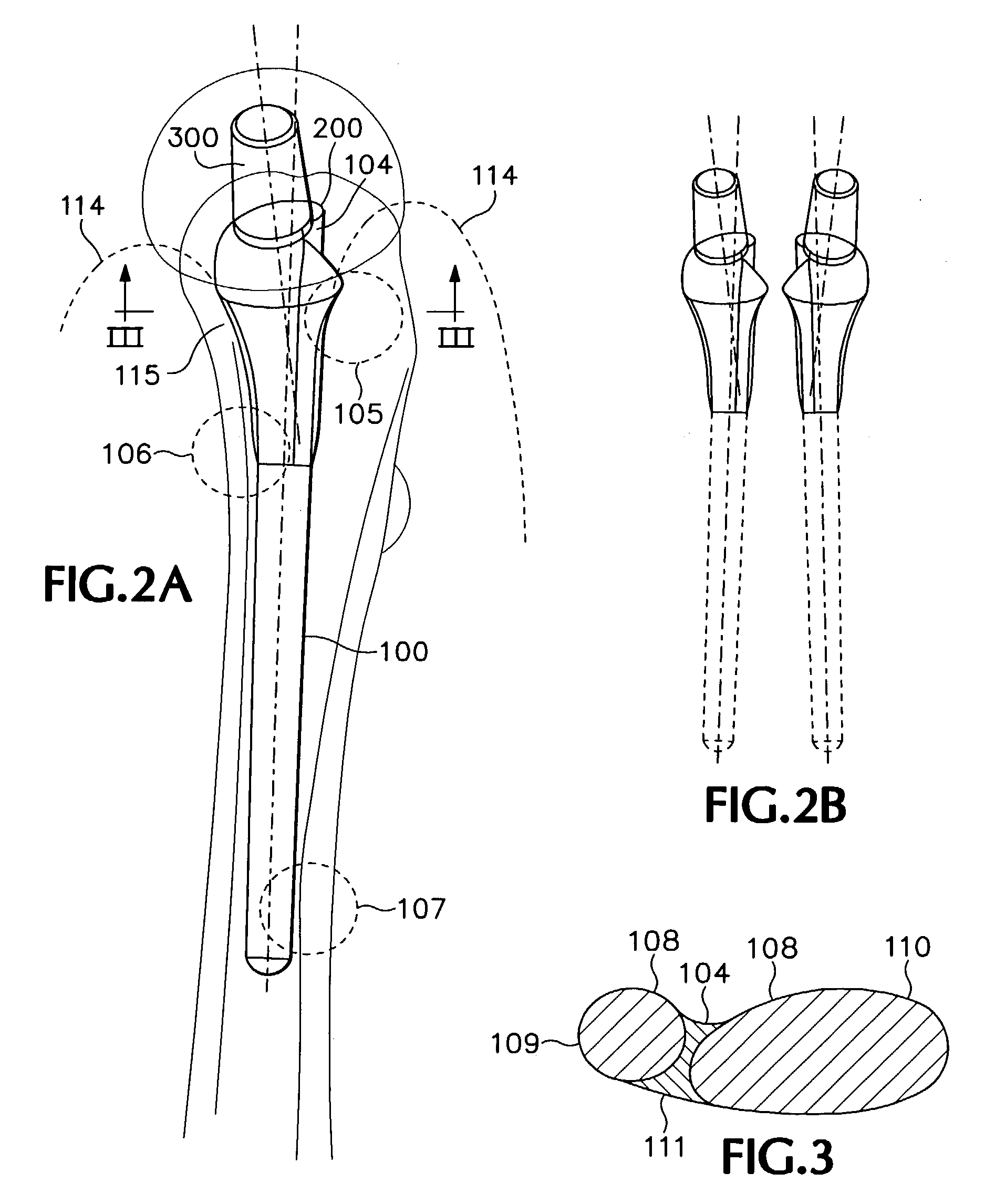

Neck-preserving-stem NPS

InactiveUS20030171821A1Improve failure rateJoint implantsFemoral headsCoxal jointCemented component fixation

The present invention essentially relates to a hip joint endoprosthesis stem for cement-free or cemented anchoring in bones that is anchored in the femural neck and in the proximal metaphysis and preserves the internal spongiosa and compact structures that reinforce the femur, that gives the design element axial access to the medullary canal, and possesses parabolically curved outer surfaces to optimize the transfer of force to the bone.

Owner:THURGAUER KANTONALBANK A CHARTERED IN & EXISTING UNDER THE LAWS OF SWITZERLAND THAT MAINTAINS ITS PRINCIPAL OFFICES AT +1

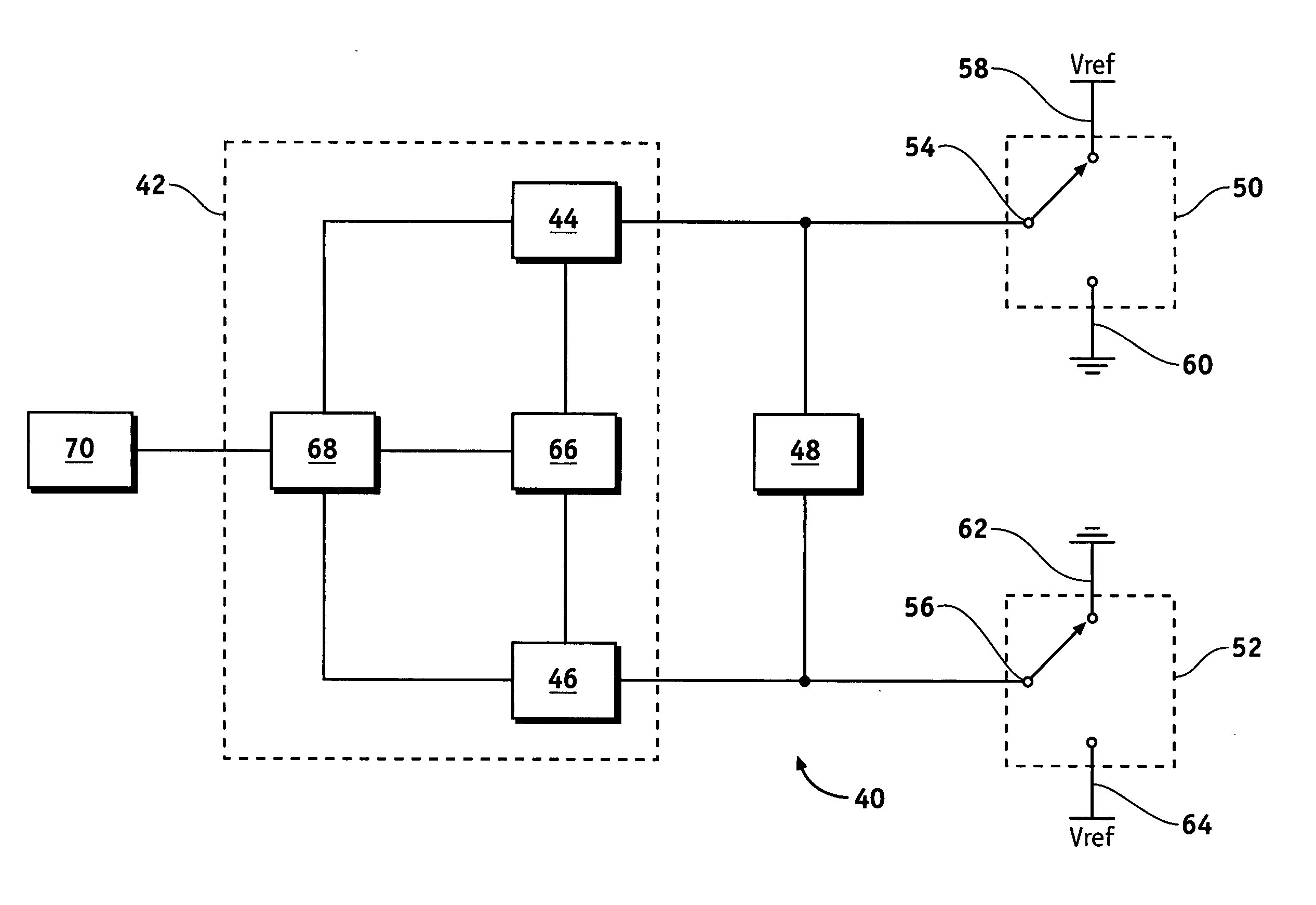

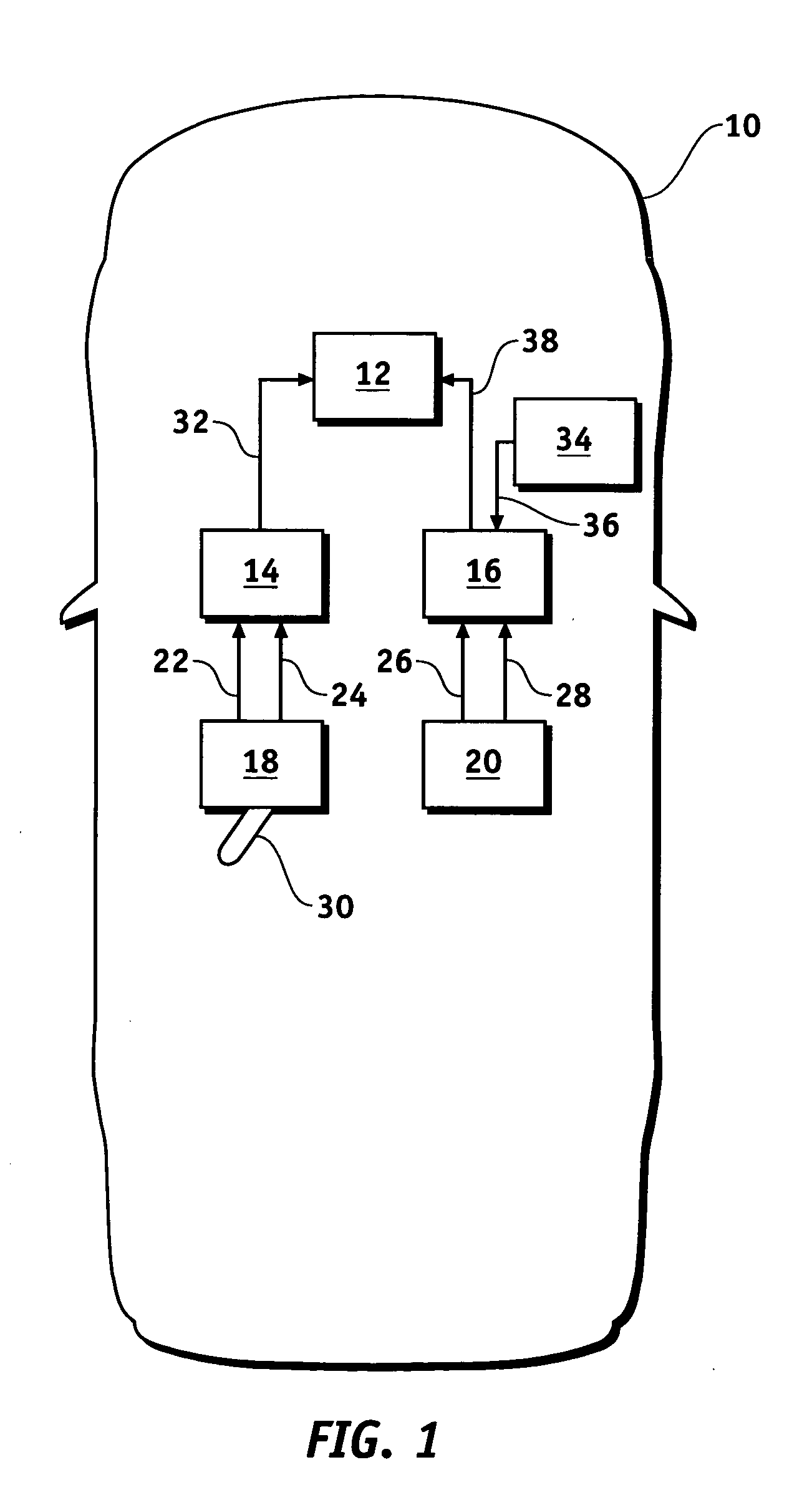

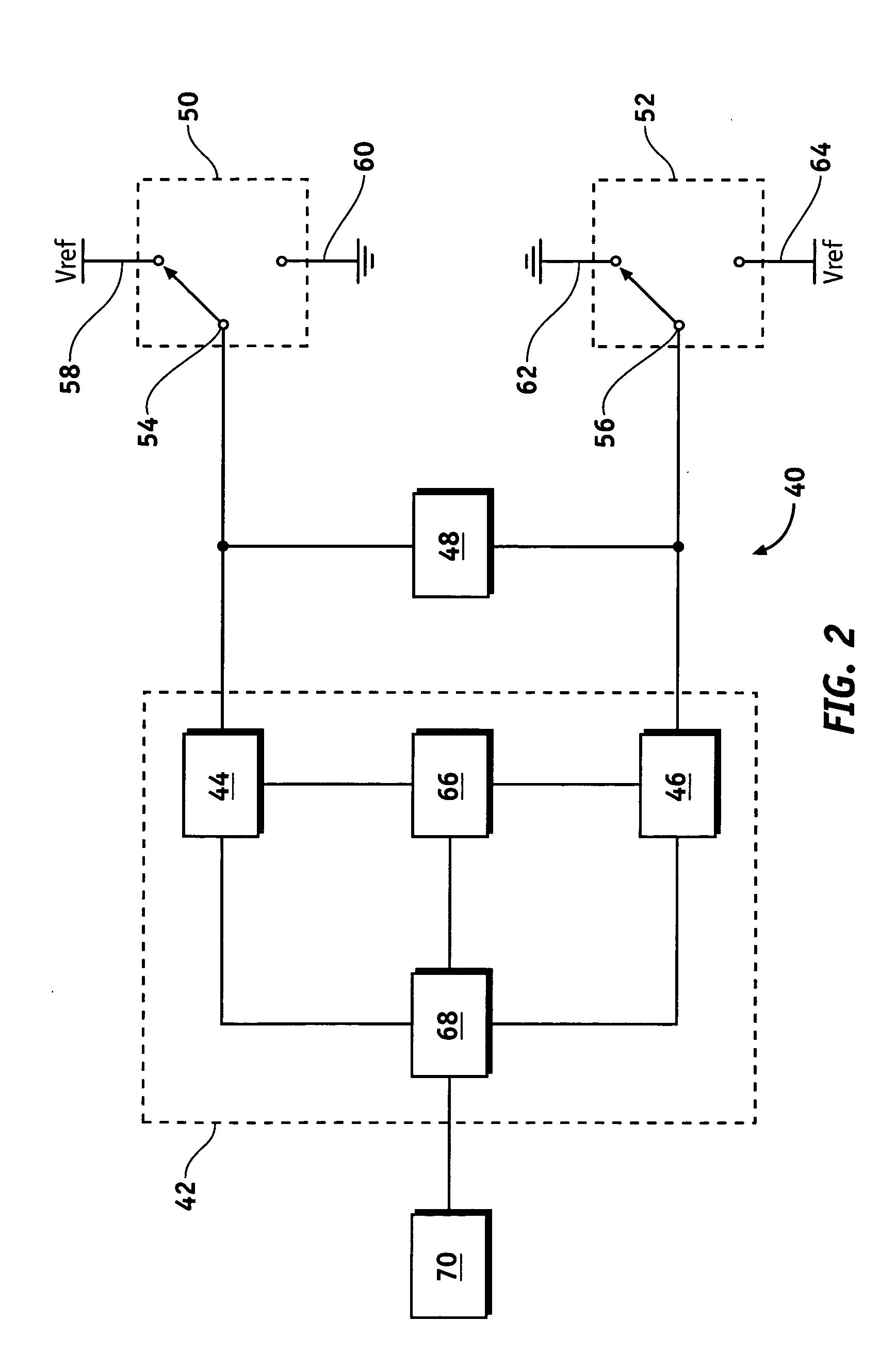

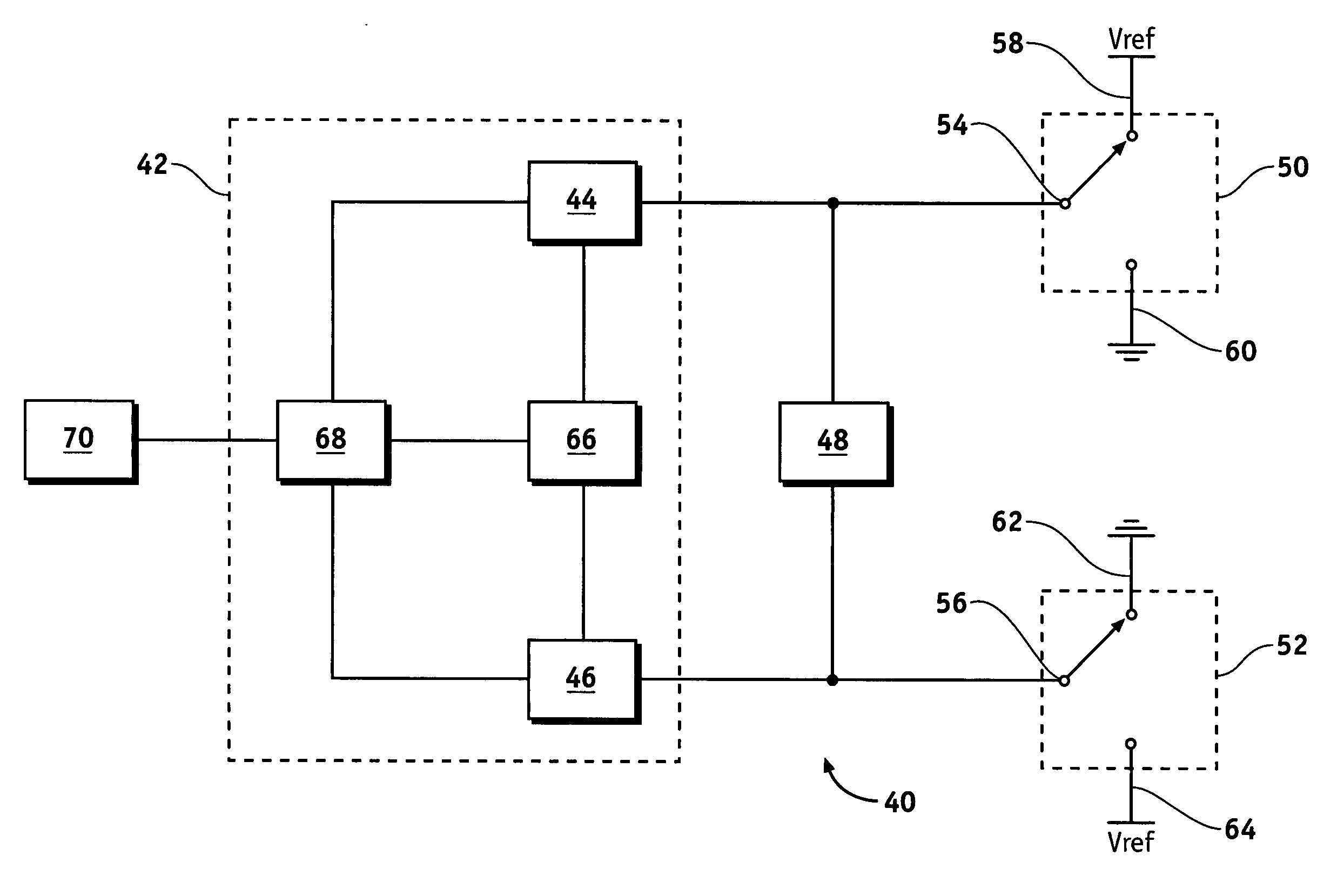

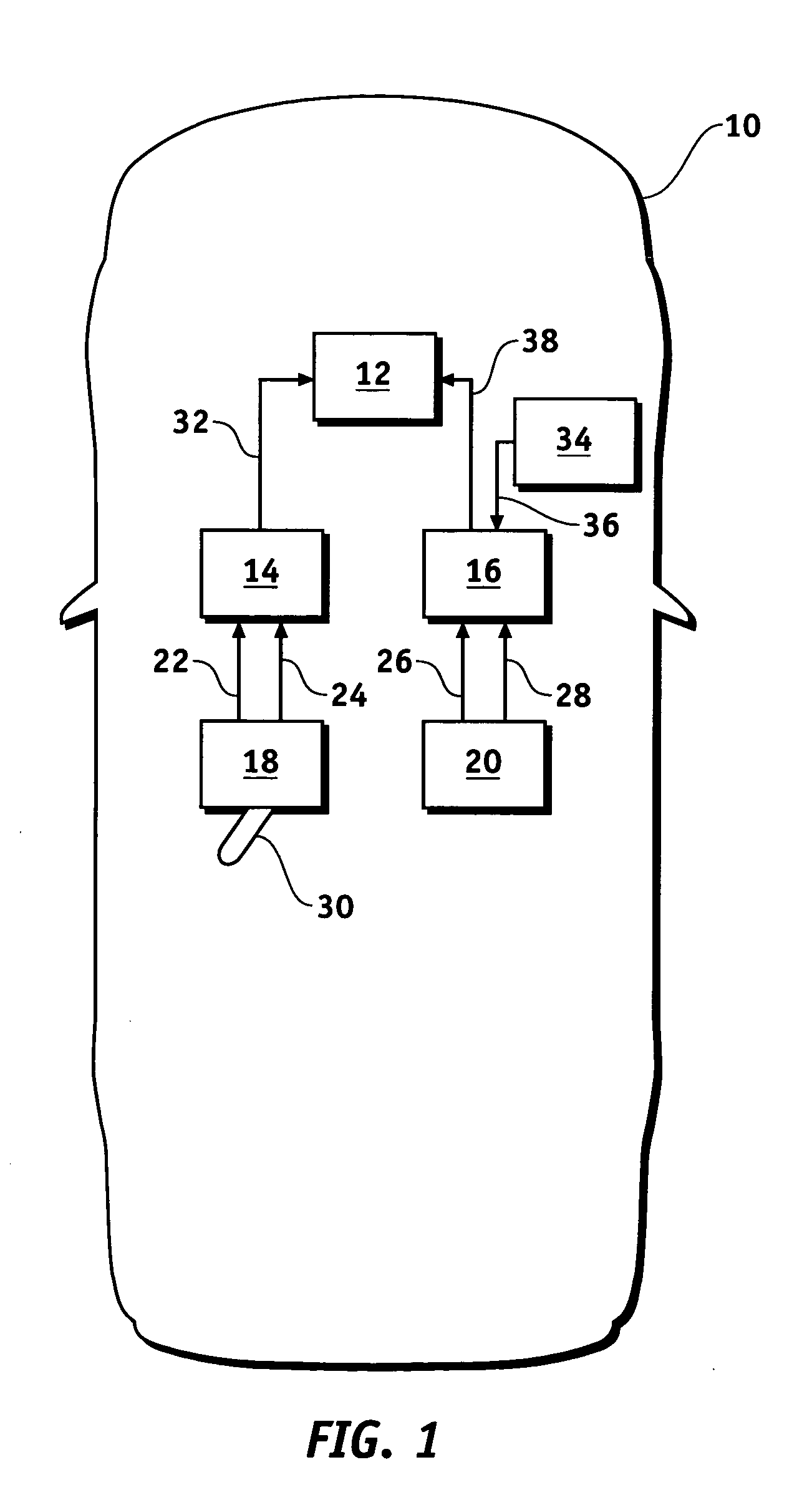

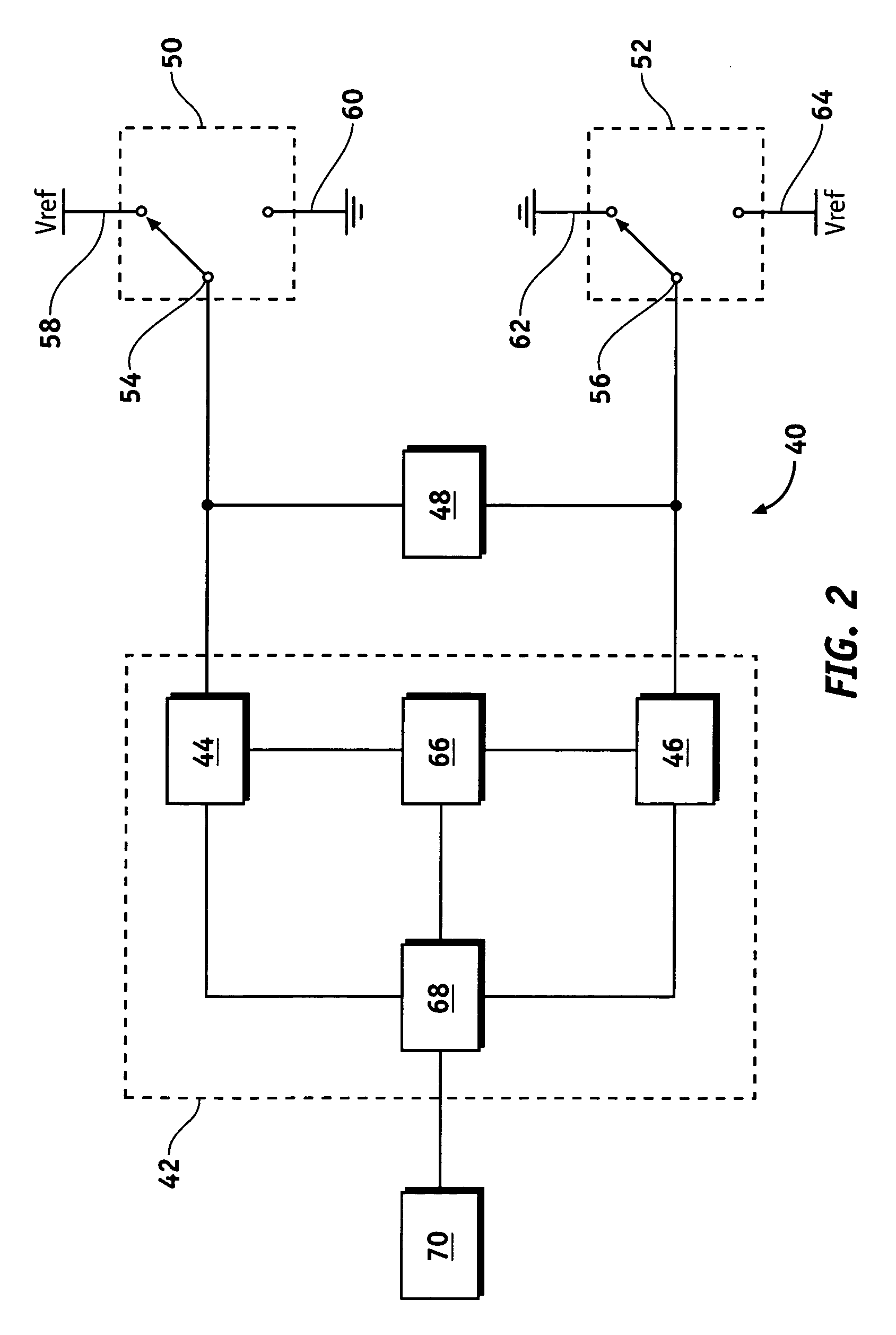

Robust power take-off and cruise enable

ActiveUS20050280311A1Improve failure rateSpeed controllerElectric devicesVoltage referencePower take-off

Apparatus are provided for robust power take off (PTO) and / or cruise enable. The apparatus includes a control module for PTO enable having a first input connected to one of a first reference voltage and a second reference voltage, and a second input connected to one of the first reference voltage and the second reference voltage. An inverse reference voltage operator is connected to both of the inputs and configured such that the second input is connected to the second reference voltage when the first input is connected to the first reference voltage and the second input is connected to the first reference voltage when the first input is connected to the second reference voltage. Based on the received voltage at the first and second inputs, the control module enables / disables PTO and / or cruise.

Owner:GM GLOBAL TECH OPERATIONS LLC

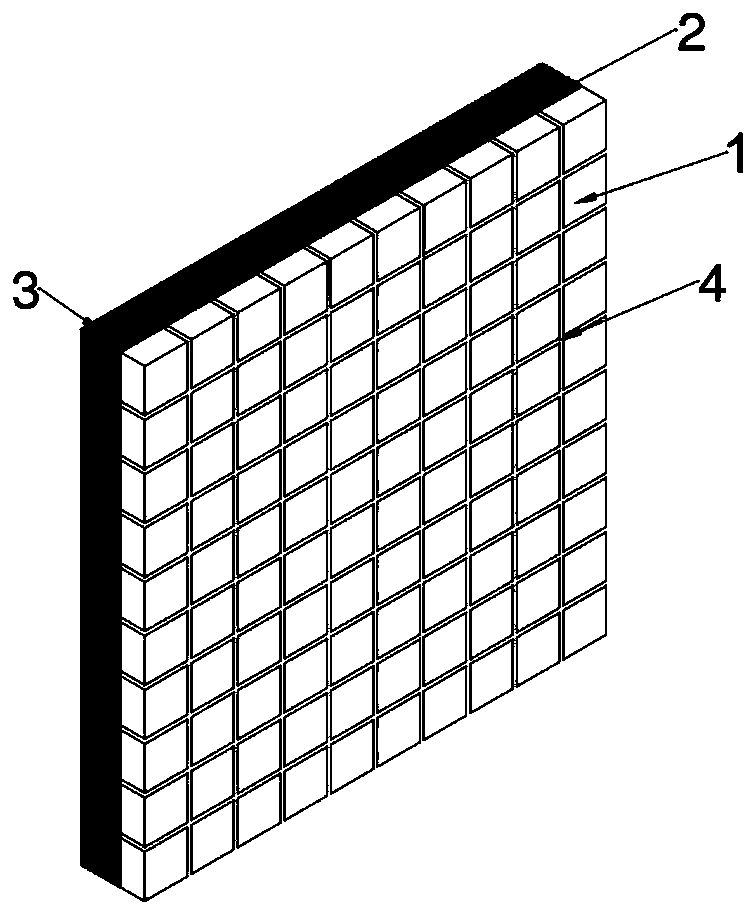

Ultra-light armor and preparation method thereof

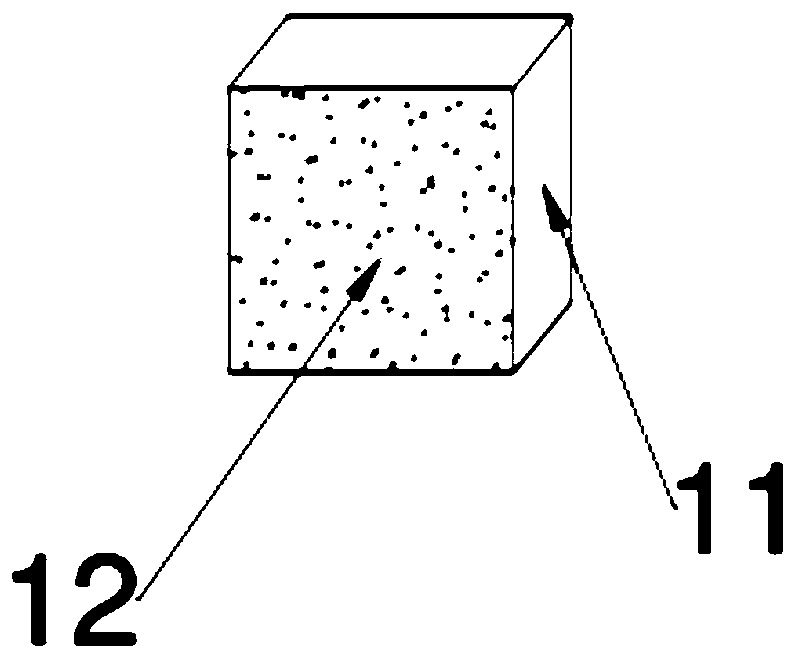

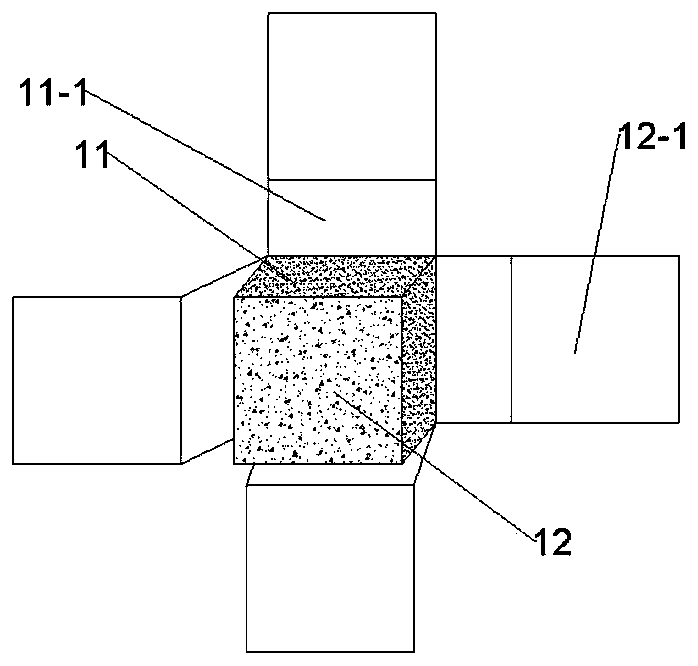

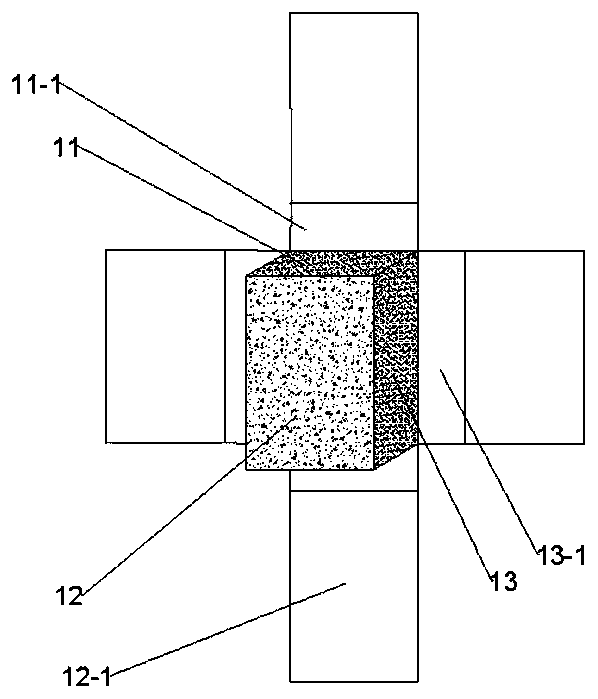

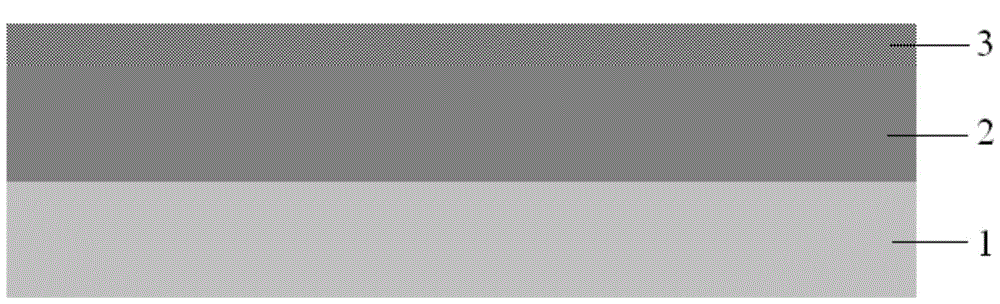

ActiveCN110631421AImproved resistance to shock loadsIncrease stiffnessProtective equipmentSynthetic resin layered productsFiberHigh energy

The invention provides an ultra-light armor which comprises a ceramic layer component, a packaging layer, a foam titanium component and a back plate; the ceramic layer component is packaged by the packaging layer; the foam titanium component is arranged on the surface of the packaging layer; the back plate is arranged on the surface of the foam titanium component; the ceramic layer component is formed by splicing ceramic small blocks; and the packaging layer is made of fiber cloth. For the ultra-light armor provided by the invention, by using foam titanium as a novel material, the problems that too large damage area and too severe deformation of the back plate caused by the fact that an armor resists high-energy impact are solved, the overall areal density of an armor plate is greatly lowered, and the multi-bullet resistance is improved. The invention further provides a preparation method for the ultra-light armor.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

Ultralight armored product and preparation method thereof

PendingCN110749235AGuaranteed protective effectIncrease incidenceProtective equipmentLaminationFiberMaterials science

The invention provides an ultralight armored product. The ultralight armored product comprises a fiber layer press plate, a metal plate bonded onto the surface of the fiber layer press plate, a fibercloth bonded onto the surface of the metal plate, a plurality of packaged small ceramic blocks bonded onto the surface of the fiber cloth, and a fiber cloth bonded onto the surfaces of the plurality of packaged small ceramic blocks, wherein the interiors of the packaged small ceramic blocks are small ceramic blocks, and the exteriors of the packaged small ceramic blocks are packaged by the fiber cloth. The ultralight armored product prevents multiple attacks; through three-dimensional wrapping packaging, the independent small ceramic blocks re-compose an integer, and the integer is high in structural strength, great in mechanical property such as bending property, anti-seismic, and resistant to collision damage; the bullet-proof capability is improved; and the ultralight armored product can be secondarily repaired and used, so that the use efficiency for a ceramic plate is increased. The invention further provides a preparation method for the ultralight armored product.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

Coil assembly structure and magnetoelectric crankshaft speed sensor

PendingCN108666068AImprove reliabilityImprove manufacturing yieldTransformers/inductances coils/windings/connectionsDevices using electric/magnetic meansMagnetizationConductor Coil

The invention discloses a coil assembly structure and a magnetoelectric crankshaft speed sensor. The coil assembly structure comprises a coil frame and a coil, wherein the coil frame has a winding groove, and the coil is wound within the winding groove of the coil frame. A sidewall of the winding groove is provided with a lead groove recessed to the outside. The lead groove extends from the insideof the winding groove outwards to a surface of the coil frame. The recess of the lead groove is filled with an incoming line of the coil, which enters the winding groove along the lead groove, so that a spacing distance created by the incoming line of the coil filling the recess is at least formed between the incoming line of the coil and an outer layer winding line of the coil. The invention canimprove voltage withstand reliability between the incoming line and coil winding line without changing the magnetization and number of windings of the coil assembly structure.

Owner:SHENZHEN SENSOR TECH CO LTD

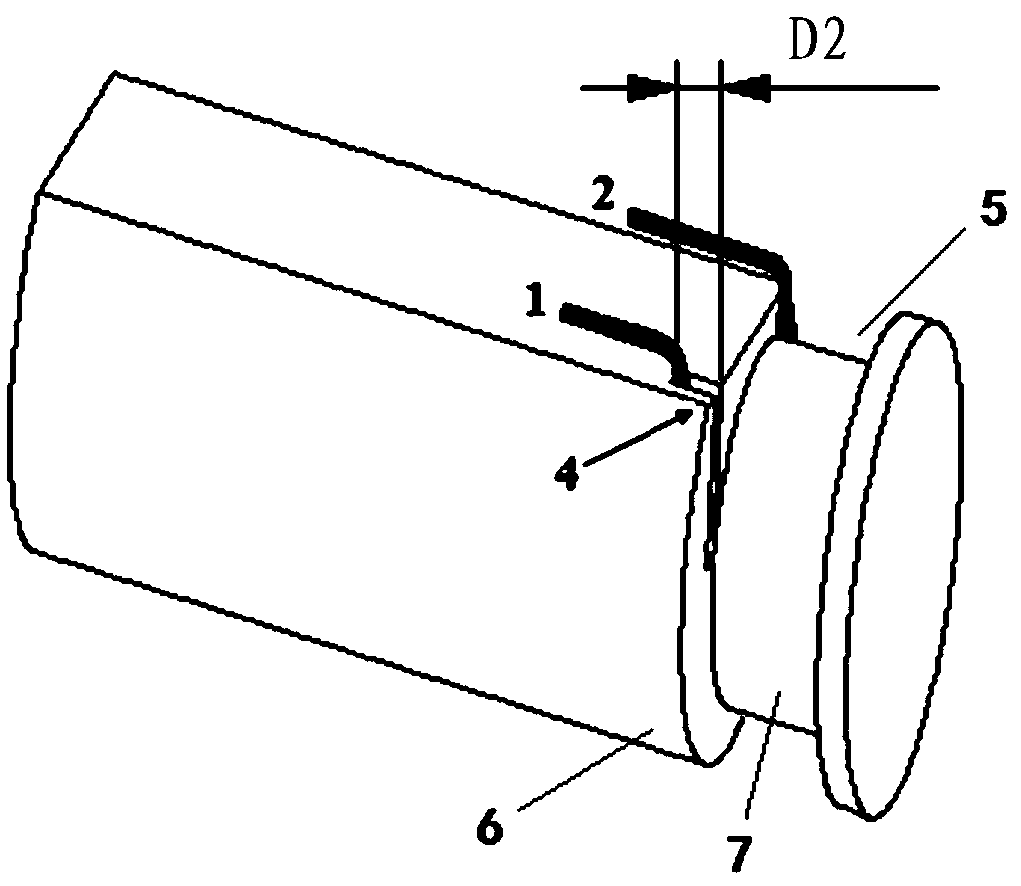

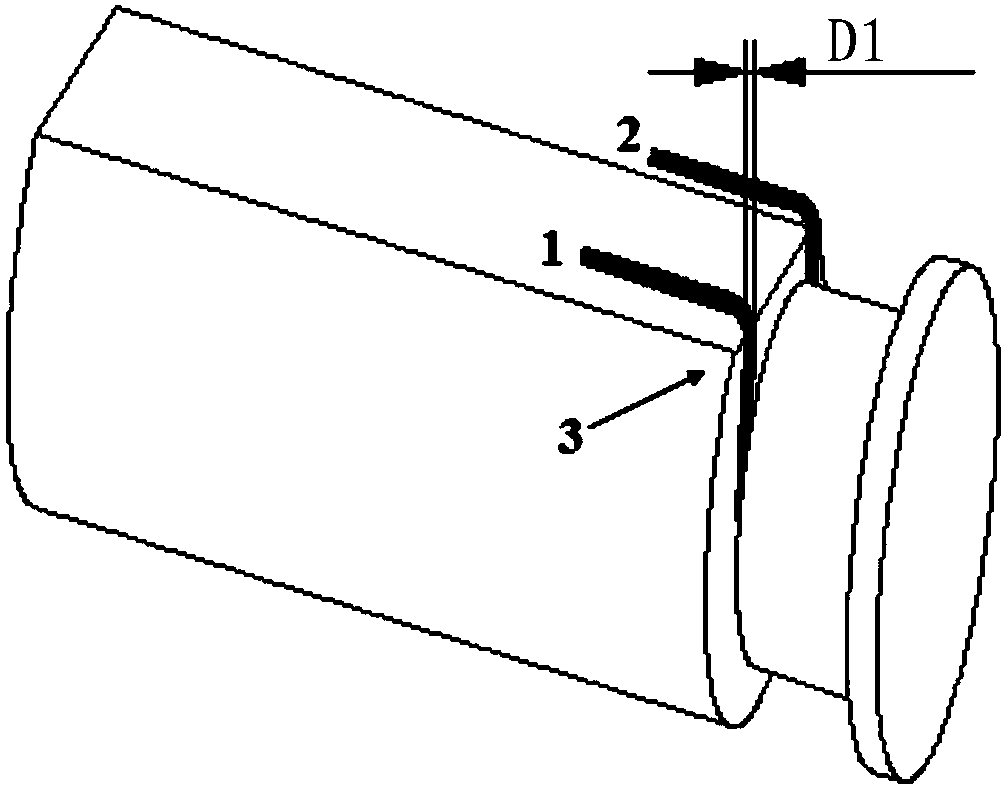

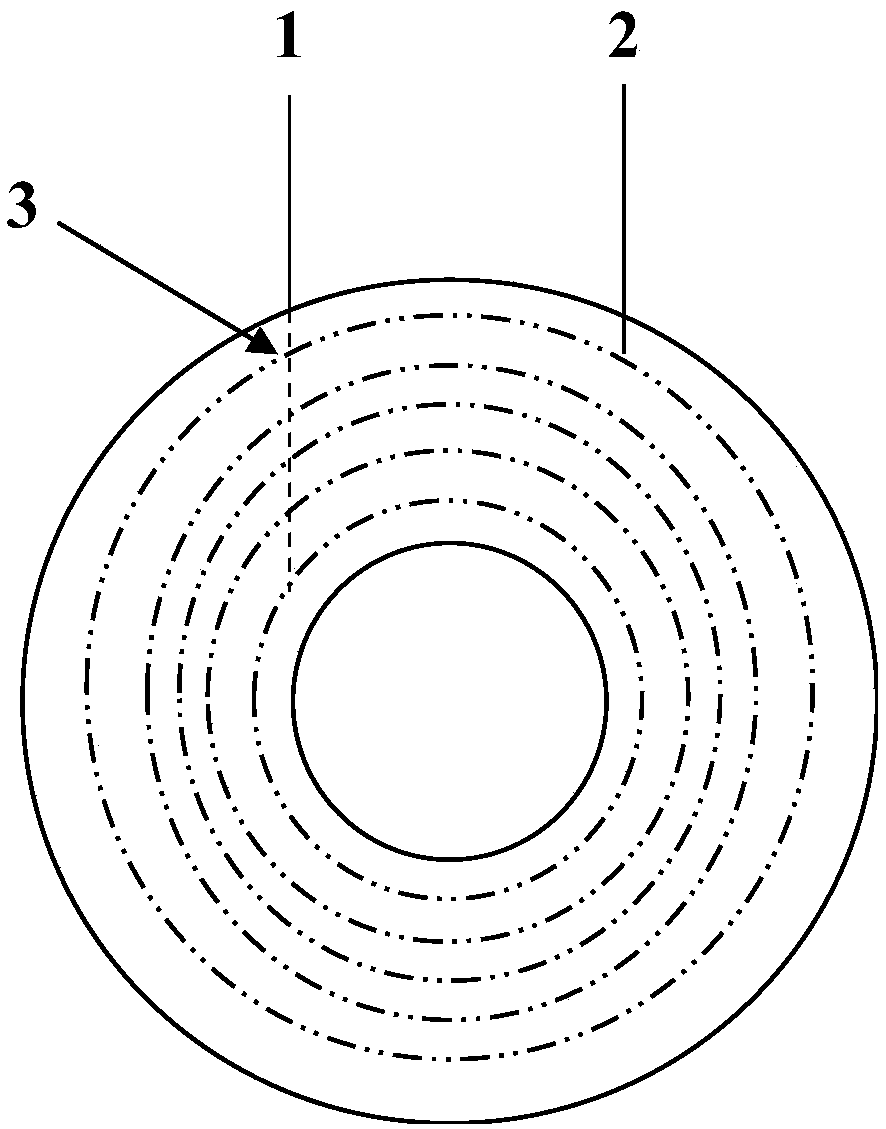

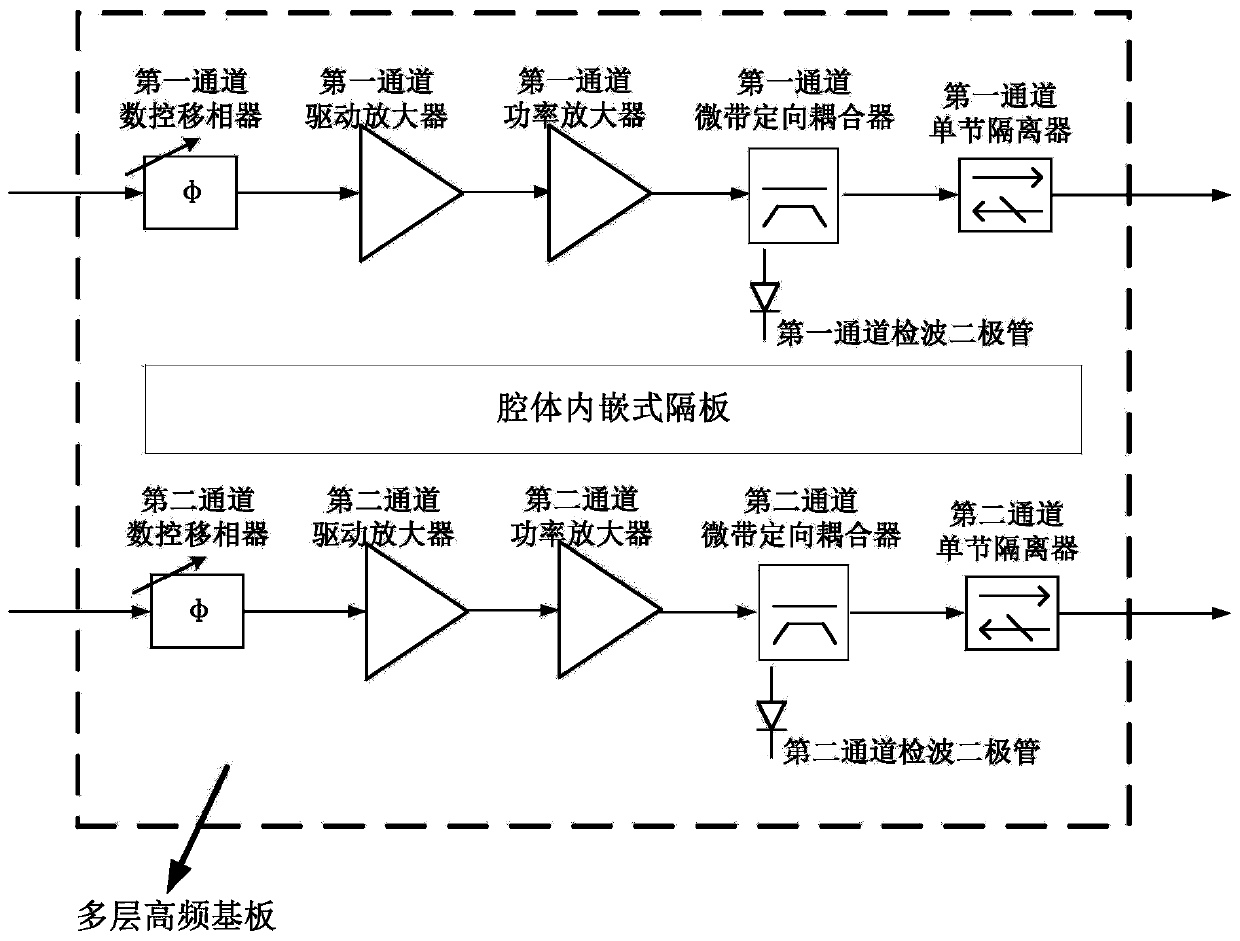

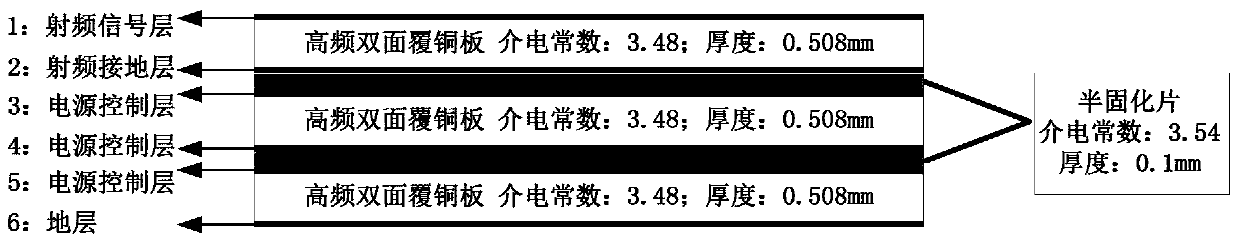

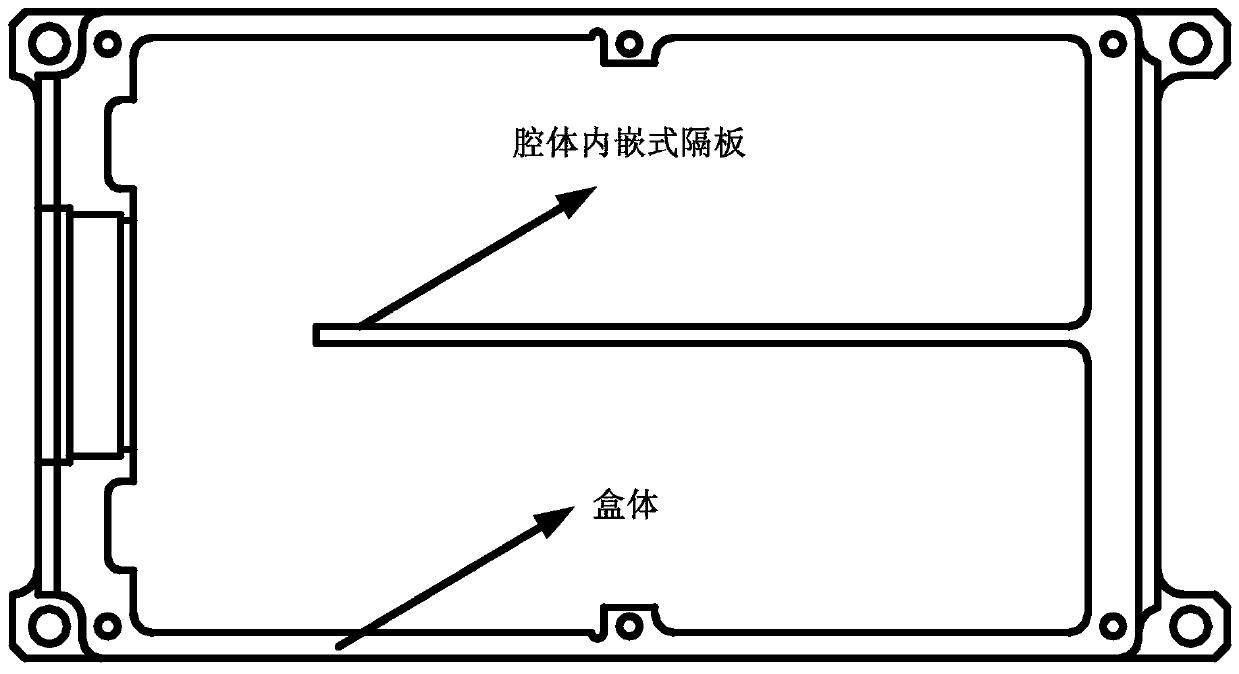

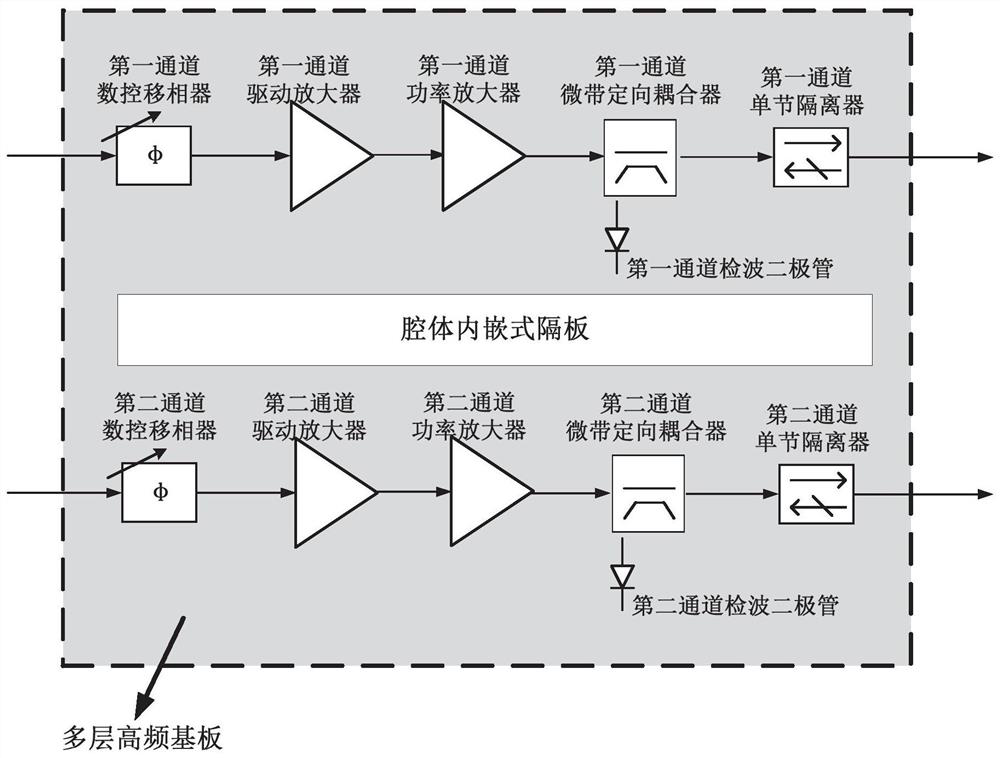

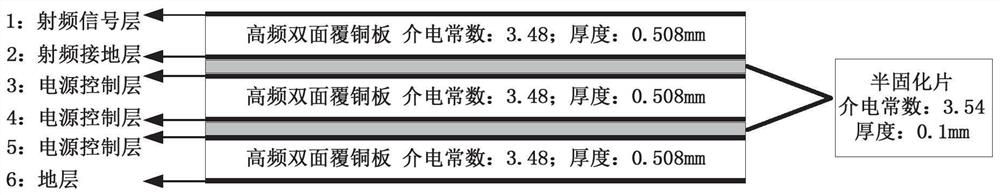

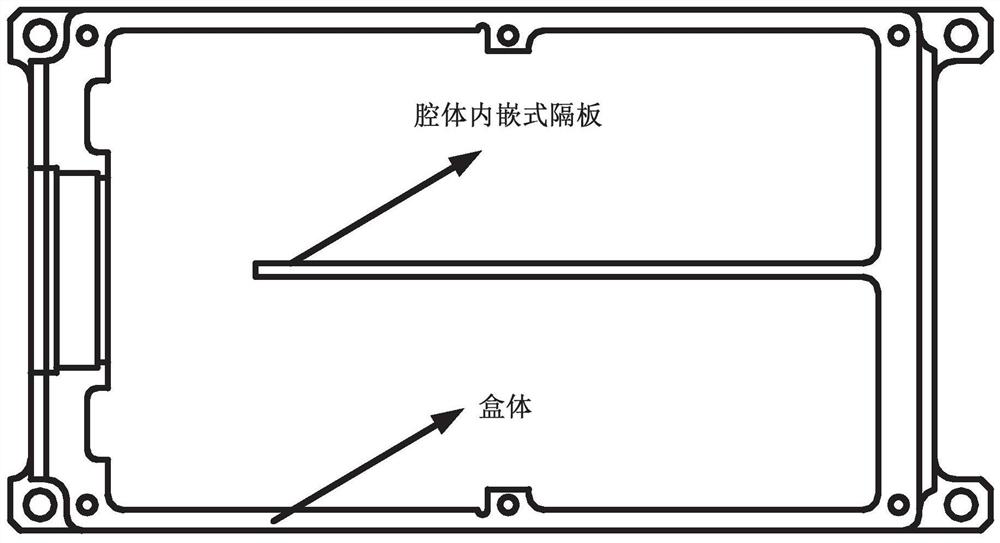

Dual-channel launching assembly for phased-array antenna of carrier rocket relay user terminal

ActiveCN110808745ACompact structureReduce front areaRadio transmissionChannel powerAerospace engineering

The invention discloses a dual-channel transmitting assembly for a phased-array antenna of a carrier rocket relay user terminal. The dual-channel transmitting assembly comprises a first channel radiofrequency circuit and a second channel radio frequency circuit, wherein the first channel radio frequency circuit comprises a first channel numerical control phase shifter, a first channel driving amplifier, a first channel power amplifier, a first channel microstrip directional coupler, a first channel single-section isolator and a first channel detection diode connected with the first channel microstrip directional coupler, which are connected in sequence; and the second channel radio frequency circuit comprises a second channel numerical control phase shifter, a second channel driving amplifier, a second channel power amplifier, a second channel microstrip directional coupler, a second channel single-section isolator and a second channel detection diode connected with the second channelmicrostrip directional coupler which are connected in sequence. Compared with a single-channel phase-shifting transmitting assembly, the phased-array antenna transmitting assembly is compact in structure, the array area of a phased-array antenna can be reduced, and the weight of the whole phased-array antenna is reduced.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

Robust power take-off and cruise enable

ActiveUS7277265B2Improve failure rateSpeed controllerCircuit-breaking switches for excess currentsComputer moduleVoltage reference

Apparatus are provided for robust power take off (PTO) and / or cruise enable. The apparatus includes a control module for PTO enable having a first input connected to one of a first reference voltage and a second reference voltage, and a second input connected to one of the first reference voltage and the second reference voltage. An inverse reference voltage operator is connected to both of the inputs and configured such that the second input is connected to the second reference voltage when the first input is connected to the first reference voltage and the second input is connected to the first reference voltage when the first input is connected to the second reference voltage. Based on the received voltage at the first and second inputs, the control module enables / disables PTO and / or cruise.

Owner:GM GLOBAL TECH OPERATIONS LLC

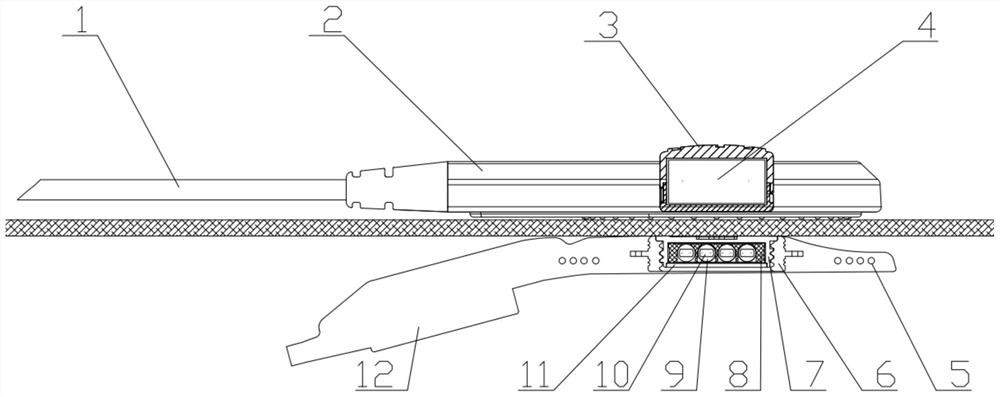

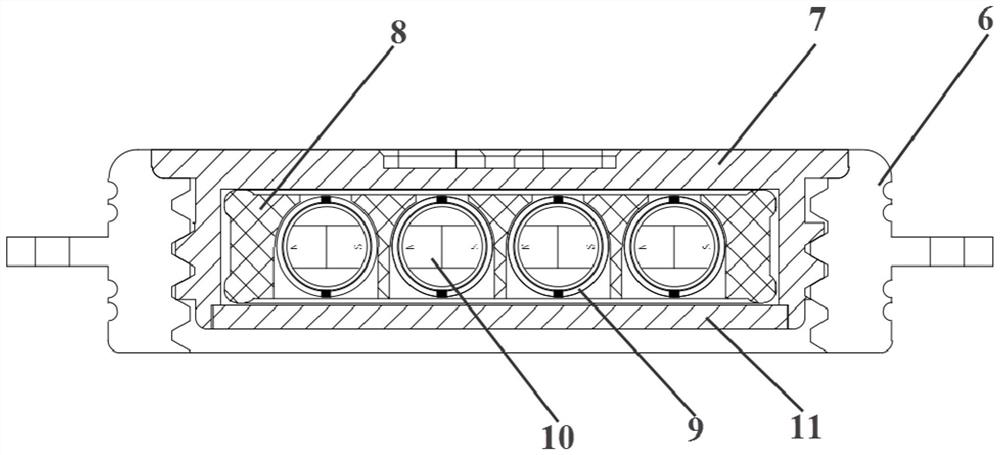

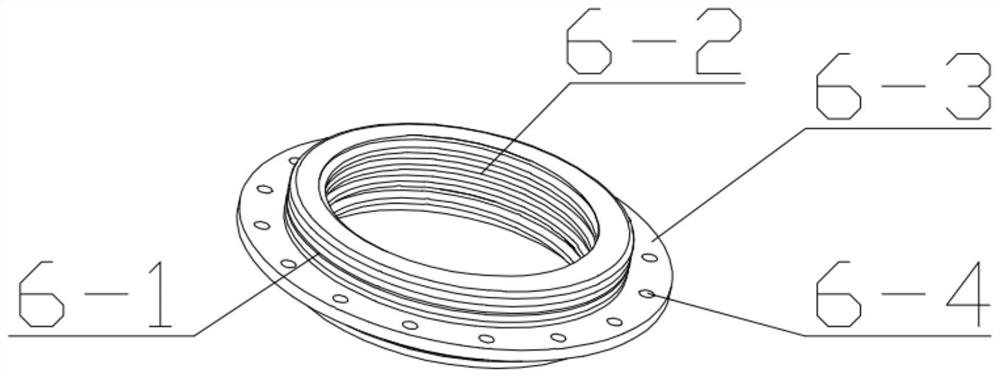

MRI-compatible artificial cochlear magnet and device

PendingCN112354079AImprove failure rateAvoid the risk of prolapseHead electrodesExternal electrodesCircular discCochlear implant magnet

The invention discloses an MRI compatible artificial cochlea magnet. The magnet comprises a base, an upper shell, a holding mechanism, a plurality of magnets and a lower shell, wherein the upper shelland the lower shell form a closed space, the holding mechanism and the magnets are contained in the closed space, the base is in a circular ring shape with threads, the bottom face of the upper shellis in a circular bowl shape, and the periphery of the upper shell is provided with threads; the lower shell is in a disc shape and covers the bowl-shaped opening of the upper shell, and the upper shell and the lower shell are assembled in the base. The magnet is arranged in the holding mechanism, consists of an N pole and an S pole which are axisymmetric, and can rotate at any angle by taking a central shaft as a center in the holding mechanism; the outer portion of the maintaining mechanism is in a cake shape, and the maintaining mechanism can rotate at any angle with the cake-shaped circlecenter as the axis in a closed space formed by the upper shell and the lower shell. The magnet can rotate at any angle in the maintaining mechanism according to the change of the direction of an external magnetic field, and the whole disc shape of the maintaining mechanism can also rotate at any angle with the circle center as the center.

Owner:ZHEJIANG NUROTRON BIOTECH

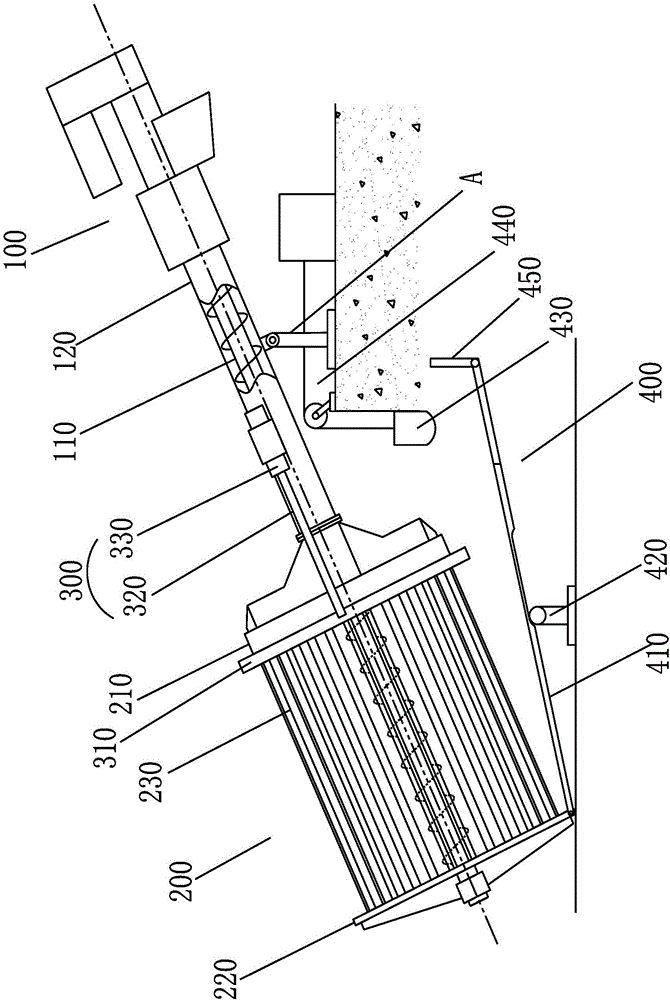

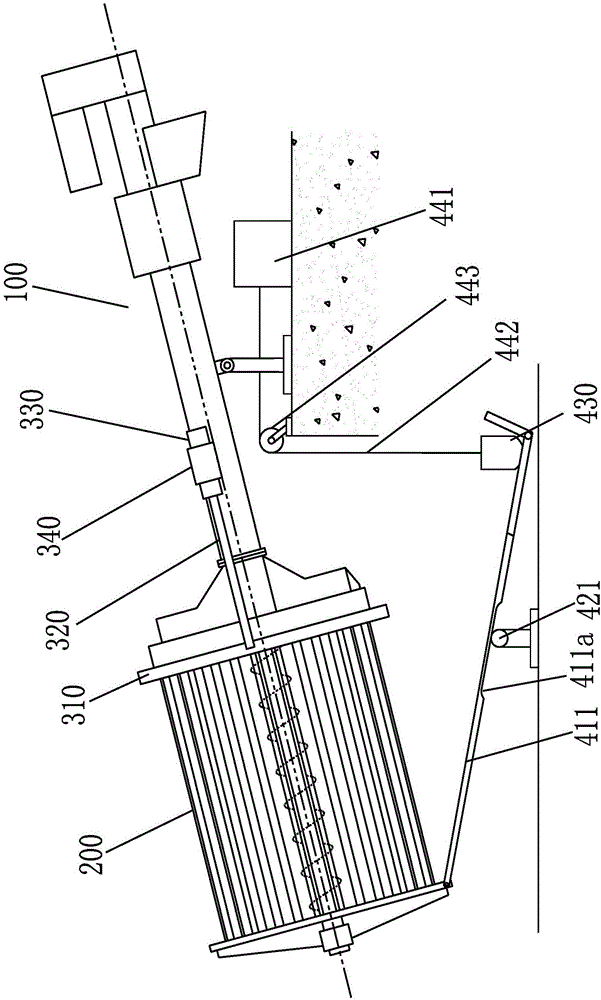

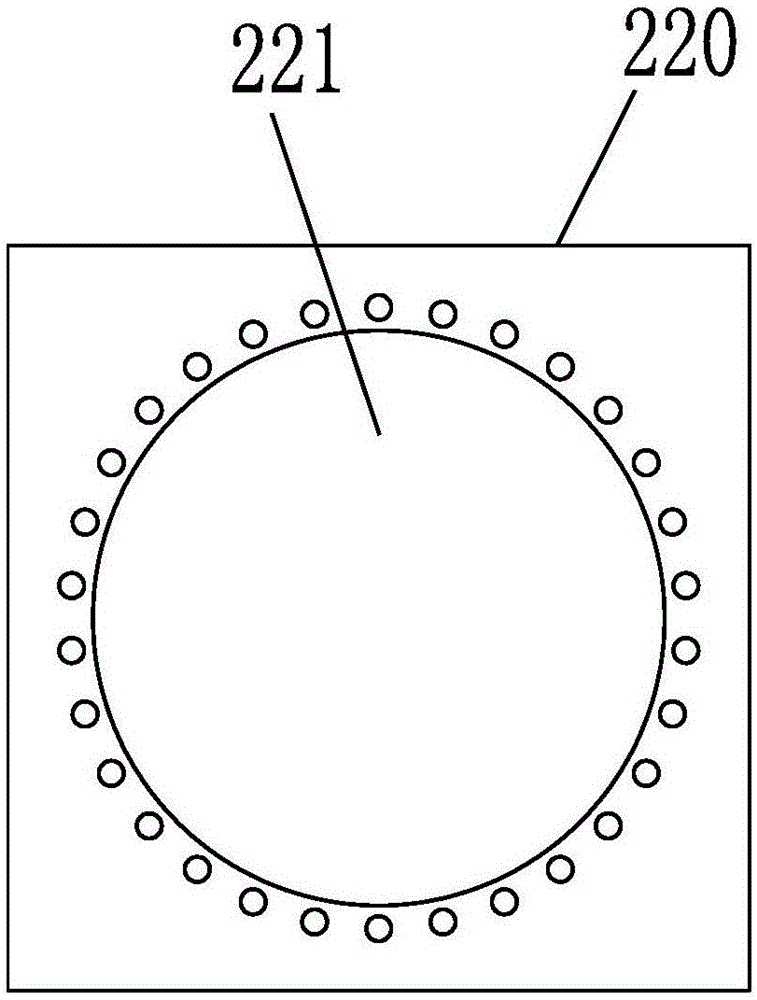

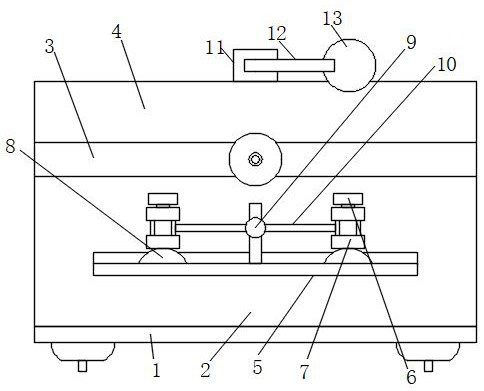

Special spiral grid decontaminating equipment for large material treatment

PendingCN106395945ANot easy to attachAffect operationTreatment involving filtrationWeight liftingFault rate

The invention provides special spiral grid decontaminating equipment for large material treatment. The special spiral grid decontaminating equipment comprises a spiral conveying component, a grid filtering component, a dreg shaving component and a lifting component, wherein the spiral conveying component comprises a spiral conveyor driven by a gear motor, the dreg shaving component is arranged on the grid filtering component, and the lifting component is connected with the grid filtering component. The grid filtering component mainly comprises an upper end plate, a lower end plate and a cylindrical filtering unit formed by surrounding of a plurality of grid bars. The dreg shaving component mainly comprises a circular dreg shaving plate, a pair of pull rods and a pair of telescopic air cylinders. The lifting component mainly comprises a U-shaped press rod, a pair of press rod supports, a balancing weight and a balancing weight lifting device. A rear-end shell of the spiral conveyor is movably connected through a ground support. The special spiral grid decontaminating equipment for large material treatment has the advantages that by novelly arranging the grid filtering component and arranging the dreg shaving component and the lifting component to cooperate with the grid filtering component, technical problems of high fault rate and uneasiness in cleaning of existing equipment are solved.

Owner:CHONGQING VOLIK ENVIRONMENTAL PROTECTION EQUIP CO LTD

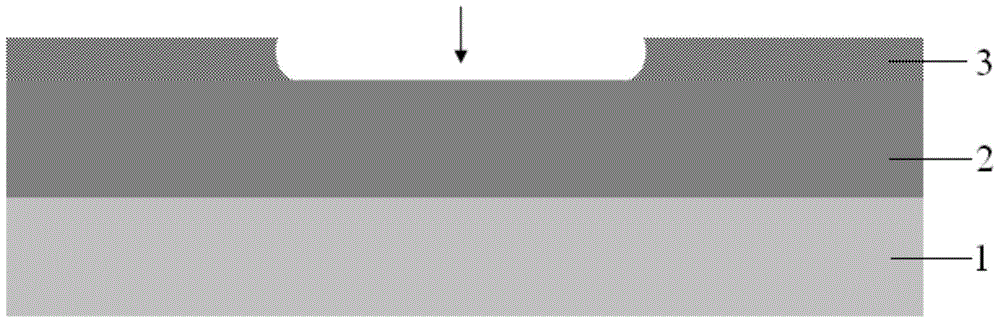

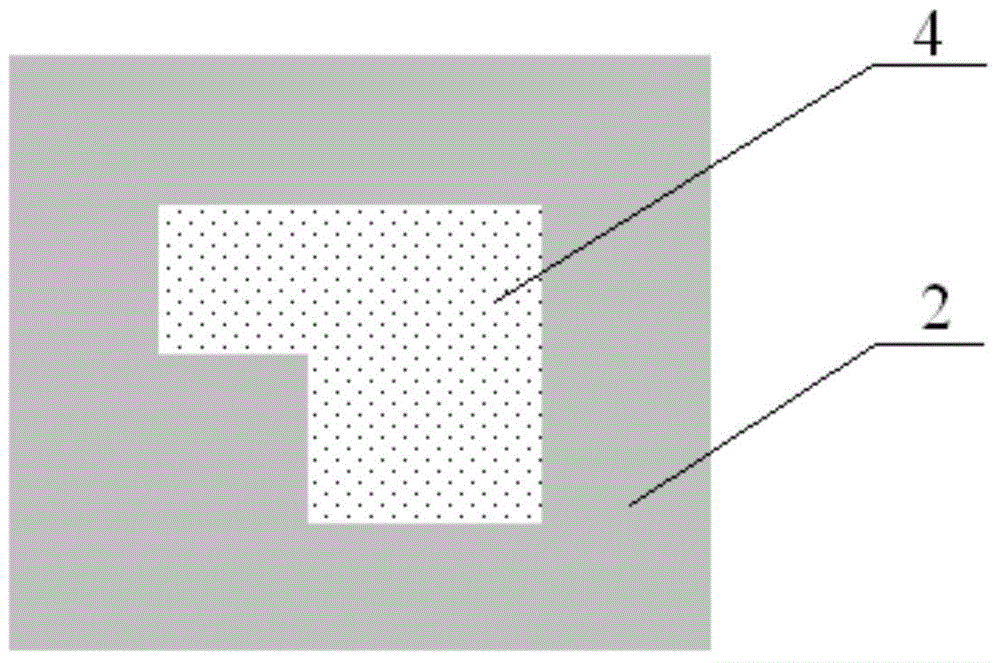

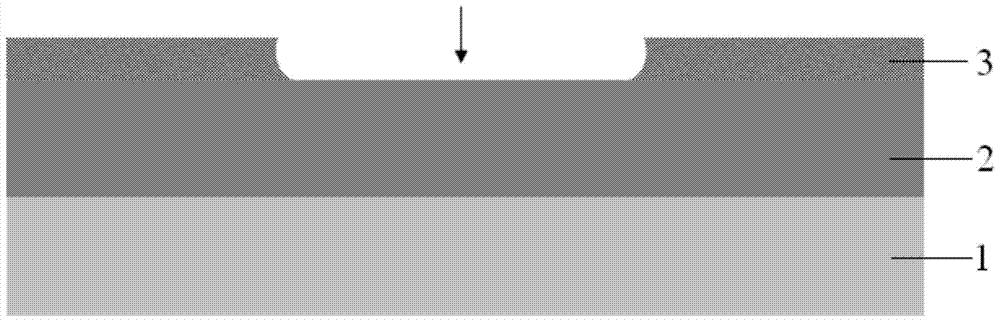

Method for improving breakdown voltage of gate oxide layer of groove-type VDMOS device

ActiveCN104681444AImprove breakdown voltageImprove failure rateSemiconductor/solid-state device manufacturingSemiconductor devicesGrid patternGate oxide

The invention provides a method for improving a breakdown voltage of a gate oxide layer of a groove-type VDMOS device. The method comprises the following steps of providing a silicon substrate with an epitaxial layer; forming an initial oxide layer on the epitaxial layer of the silicon substrate; photoetching and etching so as to form an active region pattern on the initial oxide layer; injecting ions, and forming an active region in the epitaxial layer below the active region pattern; photoetching, sequentially performing wet etching and dry etching, and forming a loop region pattern and a grid pattern on the initial oxide layer, wherein the initial oxide layer is reserved above the loop region pattern and the grid pattern; injecting ions, and forming a loop region in the epitaxial layer below the loop region pattern; forming a gate above the grid pattern. The method is capable of effectively protecting the surface of the epitaxial layer below the gate oxide layer from being damaged by processes such as etching and injection, thus obviously improving the breakdown voltage of the gate oxide layer and effectively improving an IGSS failure ratio.

Owner:FOUNDER MICROELECTRONICS INT

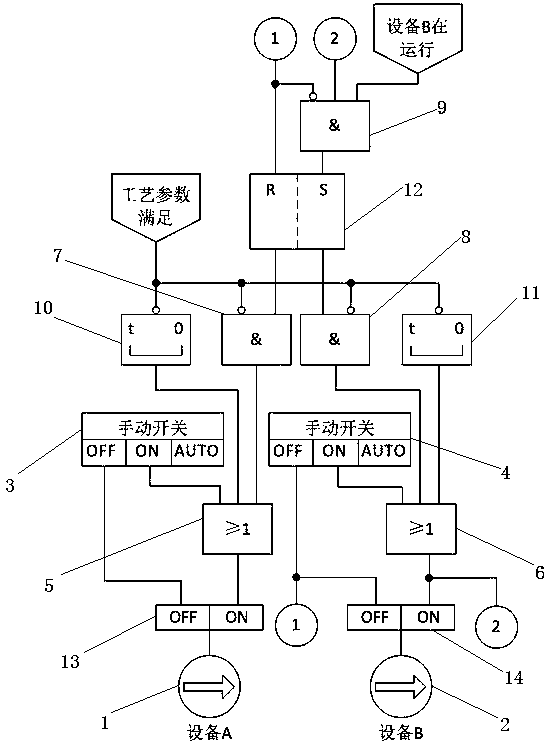

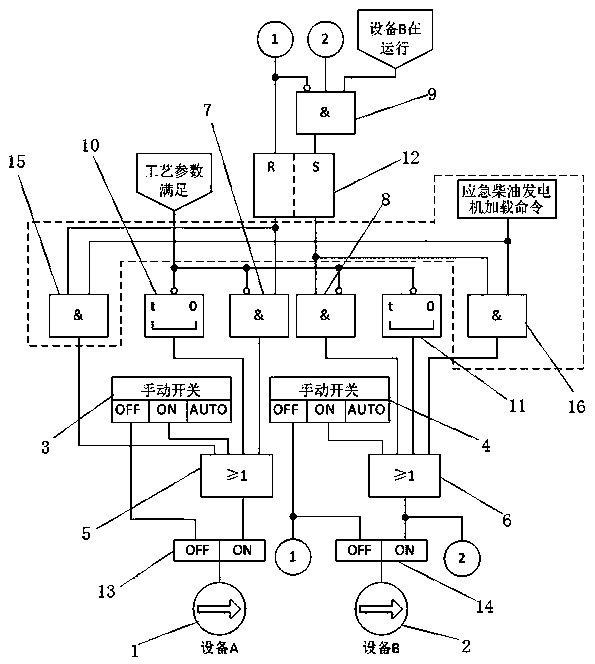

Device priority control system

ActiveCN108880513AImprove Inherent ReliabilityImprove failure rateElectronic switchingControl systemTest requirements

The invention discloses a device priority control system. The system comprises a device A and a device B, which have the same function, wherein the device A and the device B are connected in parallel;and the system further comprises a first switch module, a second switch module, a first OR gate circuit, a second OR gate circuit, a first AND gate circuit, a second AND gate circuit, a third AND gate circuit, a first time relay, a second time relay, and an RS flip-flop. The system of the invention realizes the priority control of two columns of devices that are connected in parallel and have thesame function in a nuclear power plant system through the relays, the components and parts are simple, and the inherent reliability is high; the device priority control of the system requires no controller, so that the implementation cost is low; a standby device can be automatically put into operation when the running device is faulty or when the system process parameters are not met; and the system logic design is smart, the implementation of the device priority does not affect the test requirements of the devices, and the devices having the same function do not interfere with each other during the test.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Method for increasing breakdown voltage of gate oxide layer of groove-type VDMOS (Vertical Double-diffused Metal Oxide Semiconductor) device

ActiveCN104779162AImprove breakdown voltageImprove failure rateSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingGate oxide

The invention provides a method for increasing breakdown voltage of a gate oxide layer of a groove-type VDMOS (Vertical Double-diffused Metal Oxide Semiconductor) device. The method comprises the following steps of providing a silicon substrate with an epitaxial layer, forming an initial oxide layer on the epitaxial layer of the silicon substrate, performing photoetching and etching, forming an active region graph on the initial oxide layer, performing ion injection, forming an active region in the epitaxial layer below the active region graph, performing the photoetching, forming a photoresist layer with a loop region graph and a gate graph, sequentially performing wet method etching and dry method etching, forming the loop region graph and the gate graph on the initial oxide layer, performing the ion injection, forming a loop region in the epitaxial layer below the loop region graph, removing the photoresist layer, forming a hard mask on the epitaxial layer and the initial oxide layer, performing the etching, forming a groove in the active region, removing the hard mask, and forming a gate above the gate graph. The method can effectively remove a damaged part on the surface of the epitaxial layer of the silicon substrate caused by operation such as the etching, so that the quality of the gate oxide layer of the device can be ensured.

Owner:FOUNDER MICROELECTRONICS INT

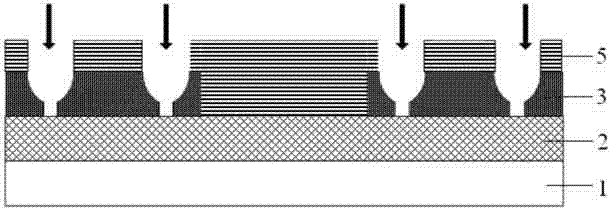

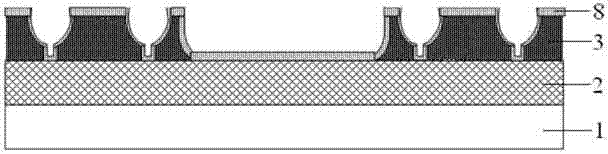

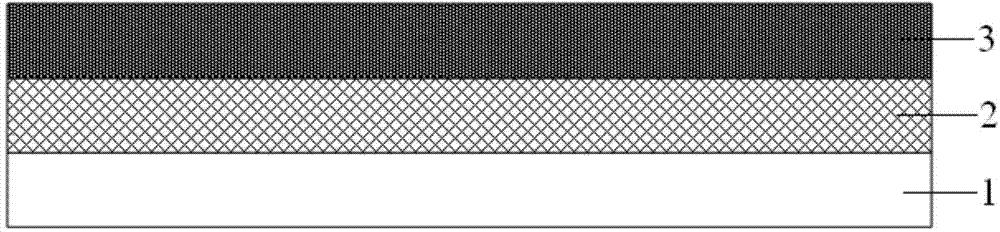

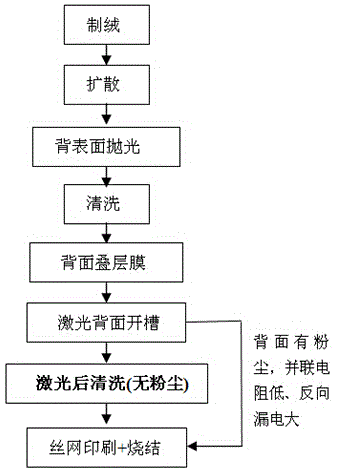

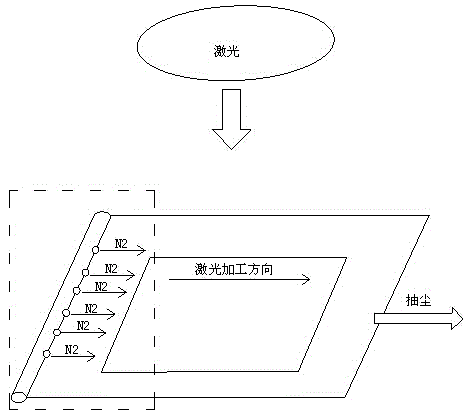

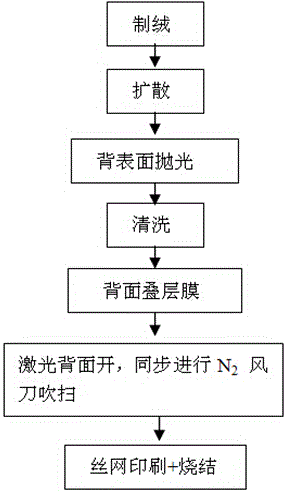

Backside laser membrane opening method and system of back passivation solar cell

InactiveCN105322052AParallel Resistor RecoveryImprove failure rateFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell

The invention discloses a backside laser membrane opening method of a back passivation solar cell. The backside laser membrane opening method comprises a laser grooving process and a dust removal process and is characterized in that the dust removal process is a pressurized gas blowing process synchronously carried out with the laser grooving process. Meanwhile, the invention also discloses a backside laser membrane opening system applying the above method of the back passivation solar cell. The backside laser membrane opening system comprises a laser grooving device and a dust removal device and is characterized in that the dust removal device is a pressurized gas blowing air knife, wherein the pressurized gas blowing air knife is arranged at a starting point position of laser grooving. By the method and the system, the problem of dust attachment during back surface laser grooving of the back passivation solar cell in the prior art is solved. With the method and the system, the back passivation process is simplified, the parallel resistance of a cell piece is improved, the reverse electric leakage is reduced, and the power loss of a module is reduced.

Owner:TRINA SOLAR CO LTD

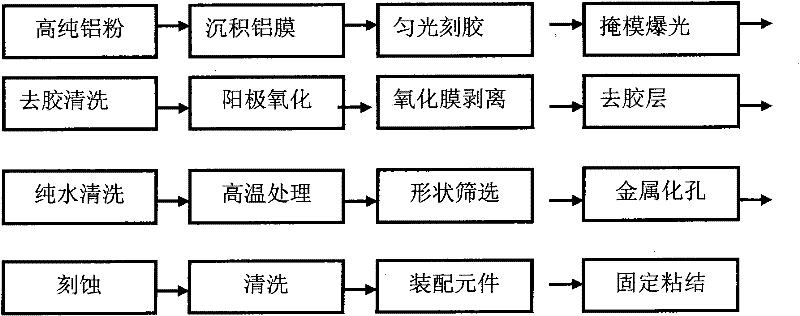

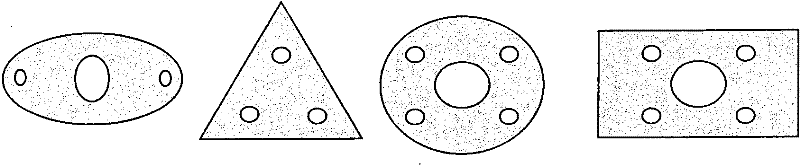

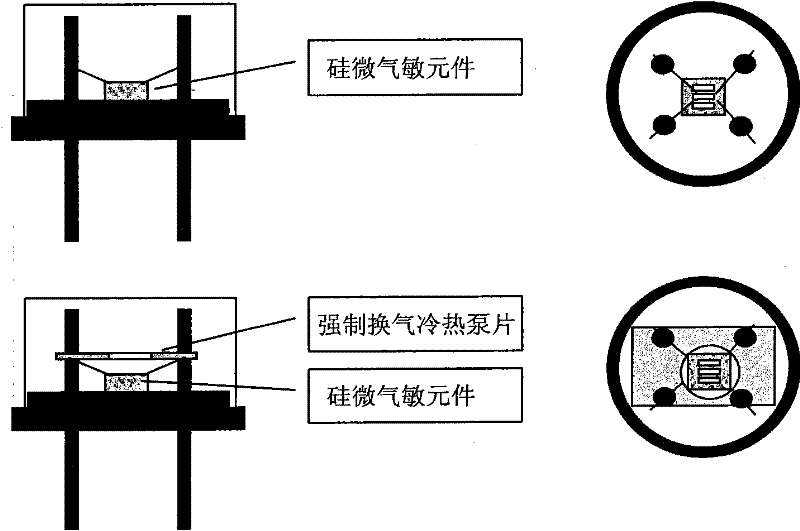

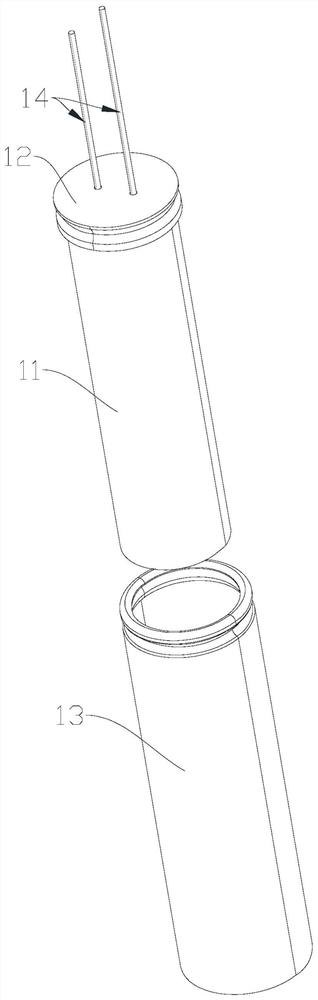

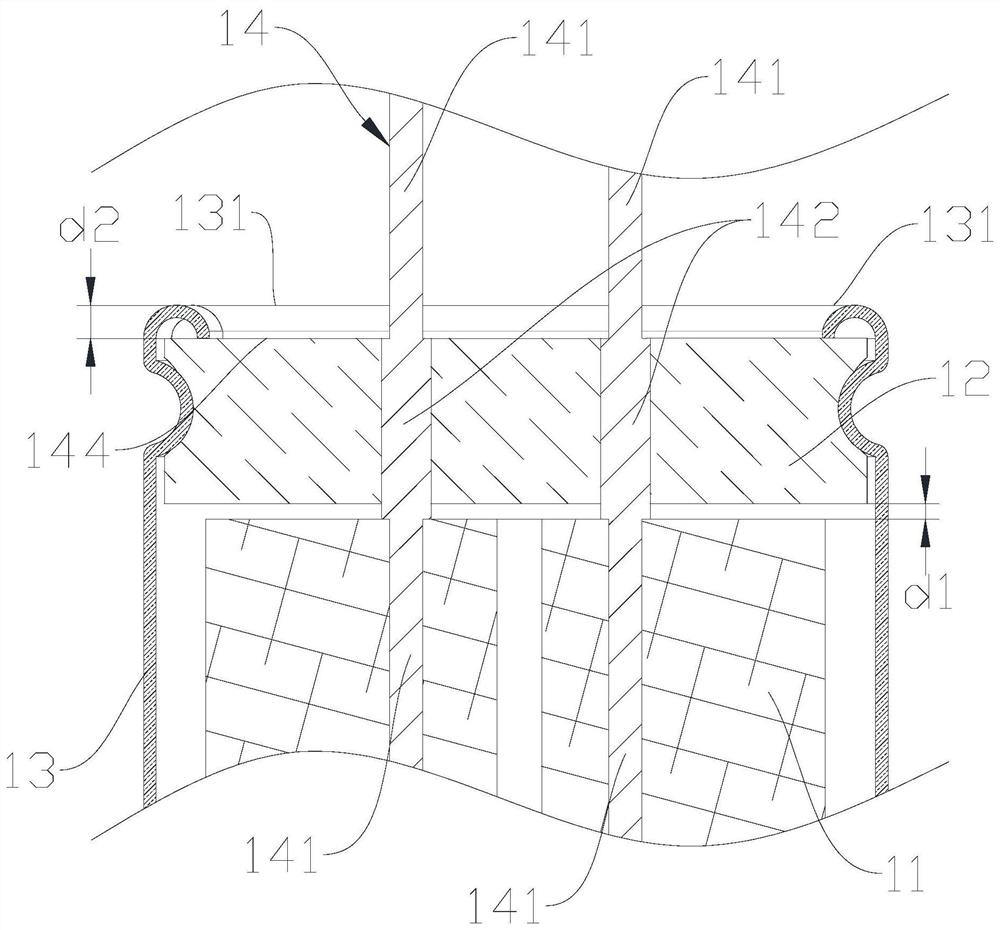

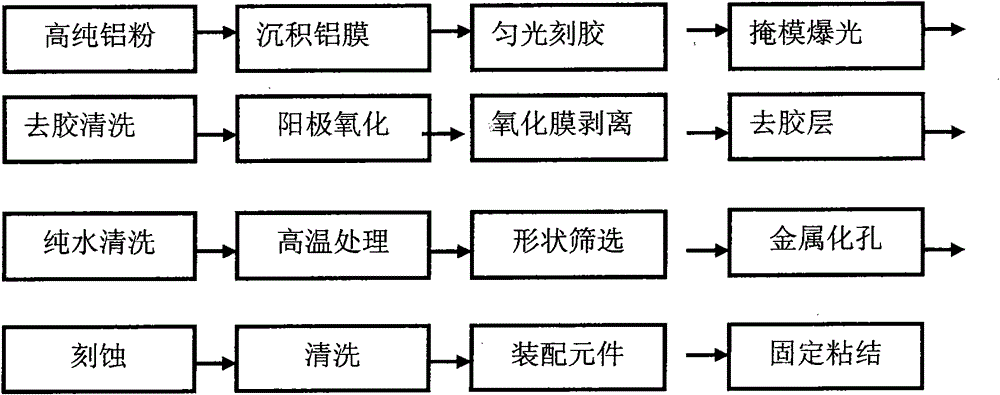

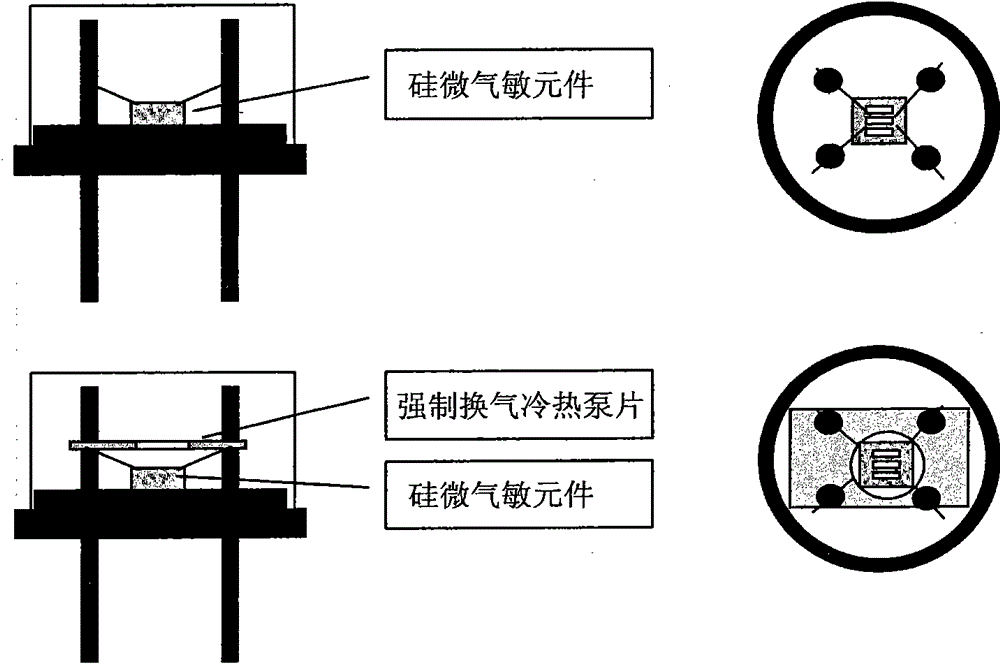

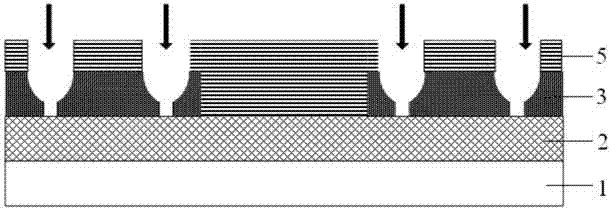

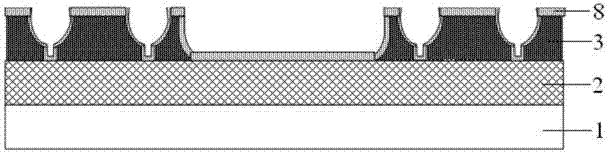

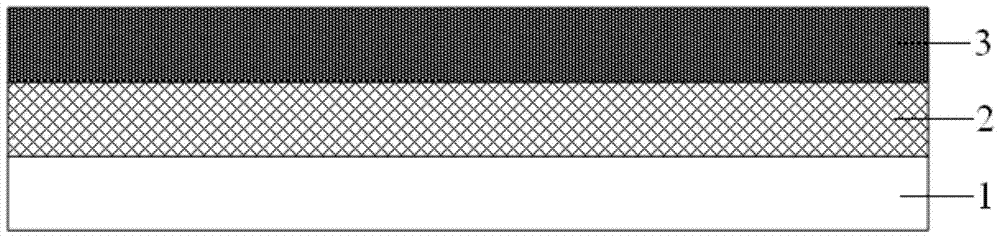

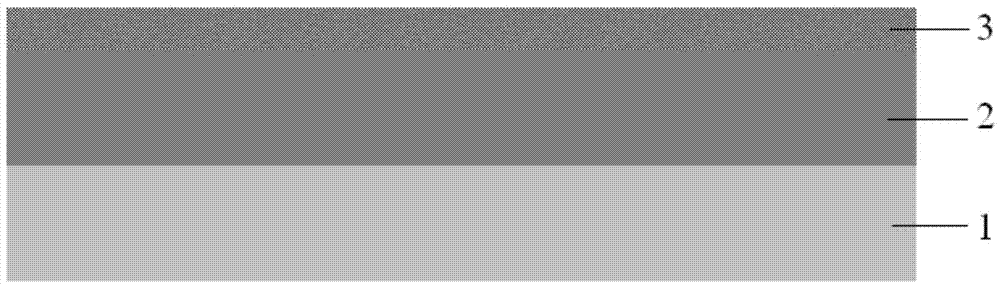

Micromachining method of gas-sensitive element with gas-exchanging forcing cold-heat pump

InactiveCN102234099AReduce linearityImprove failure rateDecorative surface effectsMaterial analysis by electric/magnetic meansProduct gasEngineering

The invention relates to the manufacture method of gas-sensitive elements, and provides a micromachining method of a gas-sensitive element with a gas-exchanging forcing cold-heat pump. With the method provided by the invention, a problem of exhausted areas easily appeared around sensitive elements is solved, linearity and performance of the gas-sensitive element is improved, and a calibration period of the gas-sensitive element is prolonged. The method comprises the following steps: deposing to obtain an aluminum film, replicating a cold-heat pump figure, manufacturing an aluminum oxide (Al2O3) film, heat treating, metallizing, and fixing by bonding. With the gas-sensitive element manufactured with the method, gas exchanging is forced between exhaust gas discharged from an element internal detection process and extraneous new gas requiring detection. A gas exchanging circulation is formed in a gas chamber of the gas-sensitive element, and validity and reliability is ensured in gas-sensitive element detection. Meanwhile, failures of the sensitive element due to coking are reduced. The invention assists in the selection and application of detecting monitors.

Owner:HARBIN JIAQI TECH DEV

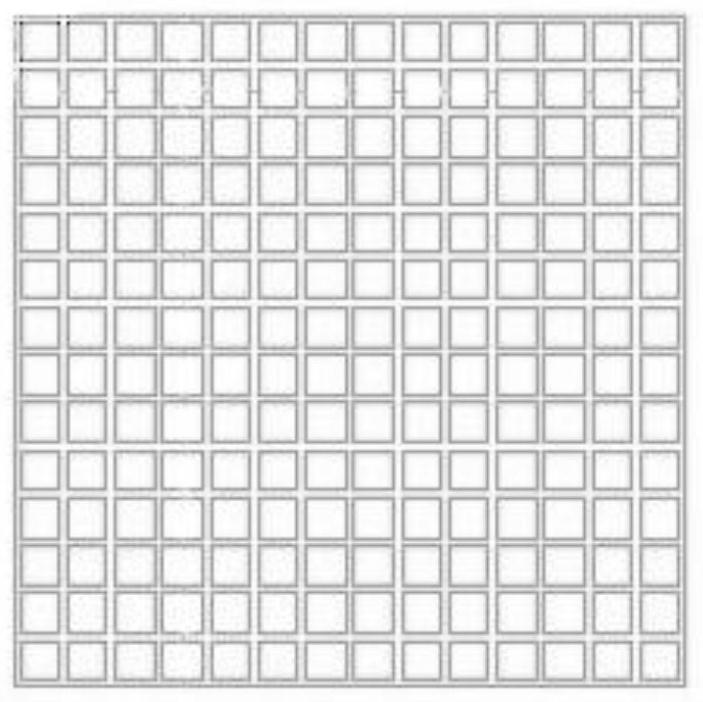

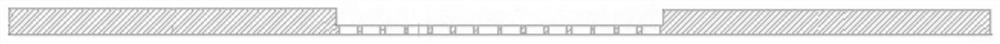

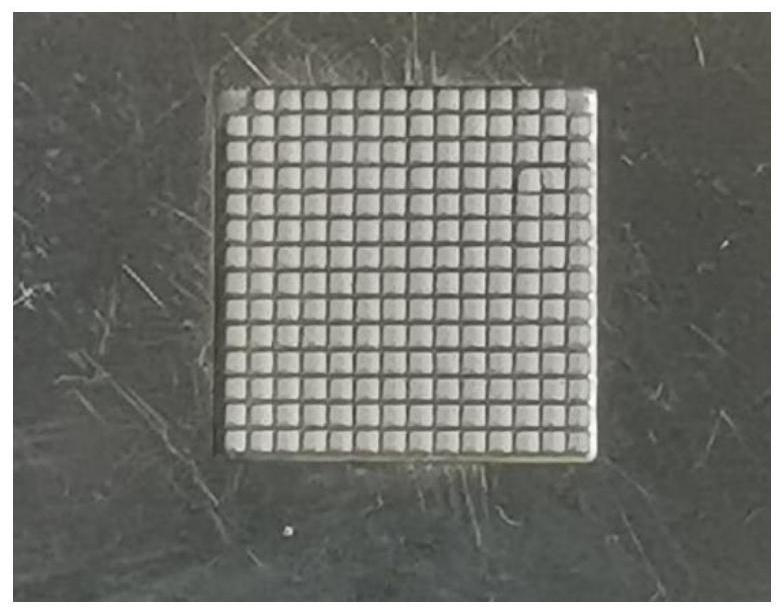

Manufacturing method of miniature thermoelectric device

ActiveCN112420912AImprove failure rateGuaranteed contact accuracyThermoelectric device manufacture/treatmentSolid-state devicesPhysicsEngineering

The invention discloses a manufacturing method of a miniature thermoelectric device. The manufacturing method comprises the following specific steps: 1) designing a steel mold according to the size and pattern of an electrode substrate of the miniature thermoelectric device; (2) placing a dispensed electrode substrate 1 in a groove of the steel mold obtained in the step (2), and enabling a glue point of the electrode substrate 1 to correspond to a through hole of a limiting plate of the steel mold; 3) putting cut thermoelectric particles into the through hole of the limiting plate of the steelmold; 4) welding the whole steel mold together with the electrode substrate 1 and the thermoelectric particles to obtain a semi-finished product of the micro thermoelectric device; and 5) after demolding the semi-finished product of the micro thermoelectric device, welding the electrode substrate 2 on the other side to obtain the micro thermoelectric device. According to the method, precise arrangement of the micro particles is achieved, meanwhile, in the welding process, the positions of the particles are fixed, the welding precision of the micro thermoelectric device substrate and the particles is guaranteed, finally, the high-precision micro thermoelectric device is manufactured, the whole process is rapid and efficient, and large-scale production and use are facilitated.

Owner:WUHAN UNIV OF TECH

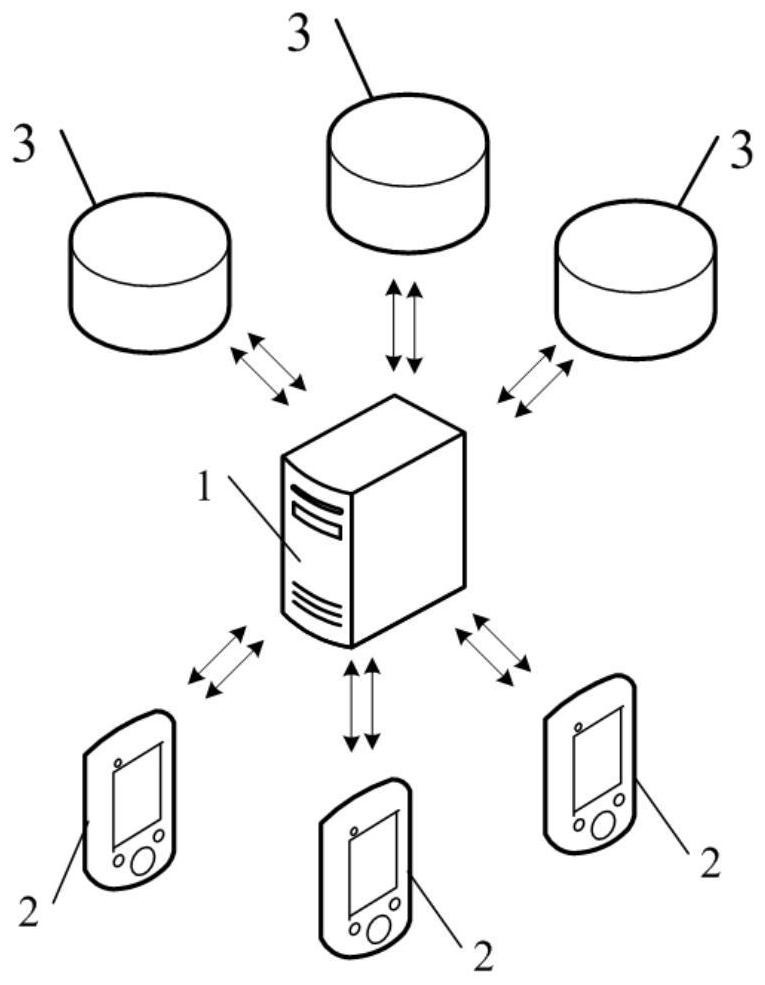

Power equipment controlling and guiding system

ActiveCN113258675AReduce difficulty of useHumanization and simplification of the use processPower network operation systems integrationCircuit arrangementsElectric power systemControl engineering

The invention provides a power equipment controlling and system. According to the invention, a guiding and controlling terminal obtains identification information of power equipment and sends the identification information to an electric power data service monitoring end; the electric power data service monitoring terminal sends electric power equipment controlling and guiding information corresponding to the identification information to the guiding and controlling terminal according to the identification information; and the guiding and controlling terminal displays the power equipment controlling and guiding information. The system enables the control of the power equipment to be more humanized and simplified, and improves the experience of operators; the power equipment gives controlling and guiding information to help an operator to learn and use the power equipment as soon as possible; and interaction is performed in a voice or video mode for guidance, so the use difficulty of the power equipment is effectively reduced, and user experience is improved. The user operation is guided through the power equipment, improper use behaviors of the user are reduced, and the stability of the power system is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

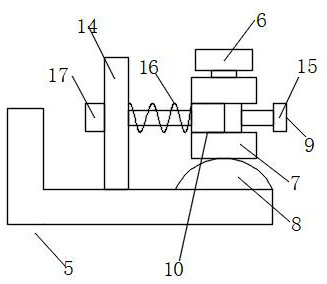

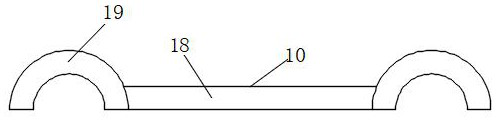

Compression atomizer

InactiveCN112121263AThe connection is not stable enoughAvoid enteringMedical atomisersStructural engineeringMechanical engineering

The invention discloses a compression atomizer. The compression atomizer comprises a bottom cover, a main body, a side belt and an upper cover, wherein a fixing plate is arranged on the surface of themain body, the fixing plate comprises a vertical part and a horizontal part, fixing rods are symmetrically arranged on the surface of the horizontal part of the fixing plate, and a rotary drum is arranged on the outer side of each fixing rod in a sleeving manner; a pressing mechanism is arranged on the surface, located between the two fixing rods, of the horizontal part of the fixing plate, the pressing mechanism comprises a stabilizing rod, a pressing rod, a first spring and a connecting block, the stabilizing rod is in a vertical state, a limiting mechanism is arranged on the outer side ofthe pressing rod, and the limiting mechanism comprises a connecting plate and two limiting half rings; and the pressing rod sequentially penetrates through the connecting plate, the first spring and the stabilizing rod and is connected with the connecting block. An overlong air supply pipe is wound in annular grooves in the rotary drums for several circles, the air supply pipe is pressed by the limiting semi-rings, and the situation that connection is not stable enough due to the fact that the overlong air supply pipe is pulled is avoided.

Owner:珠海凌特医学仪器有限公司

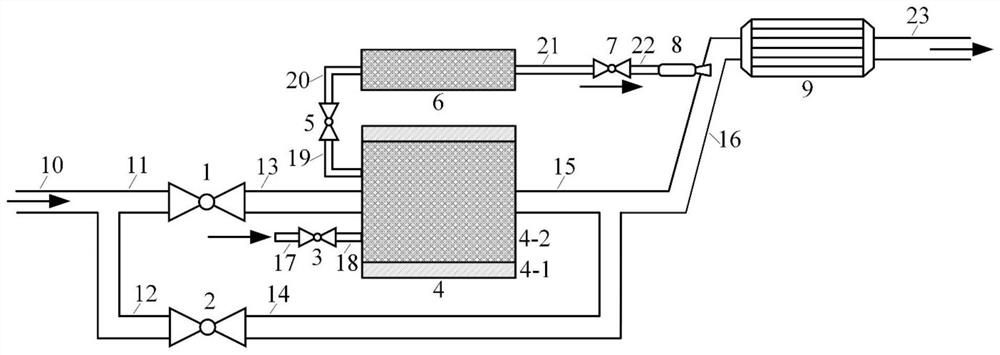

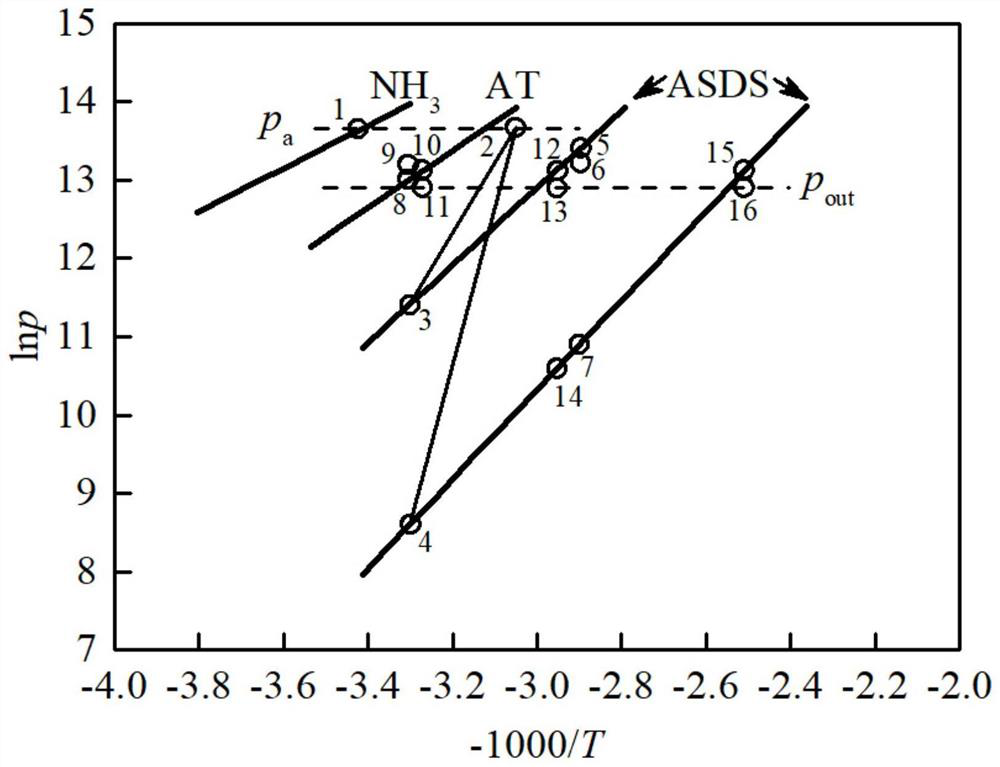

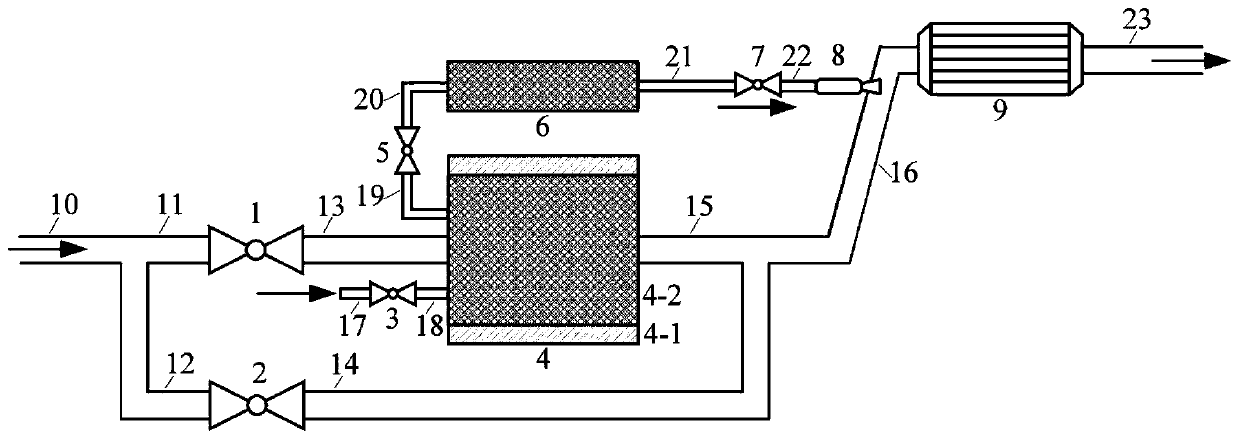

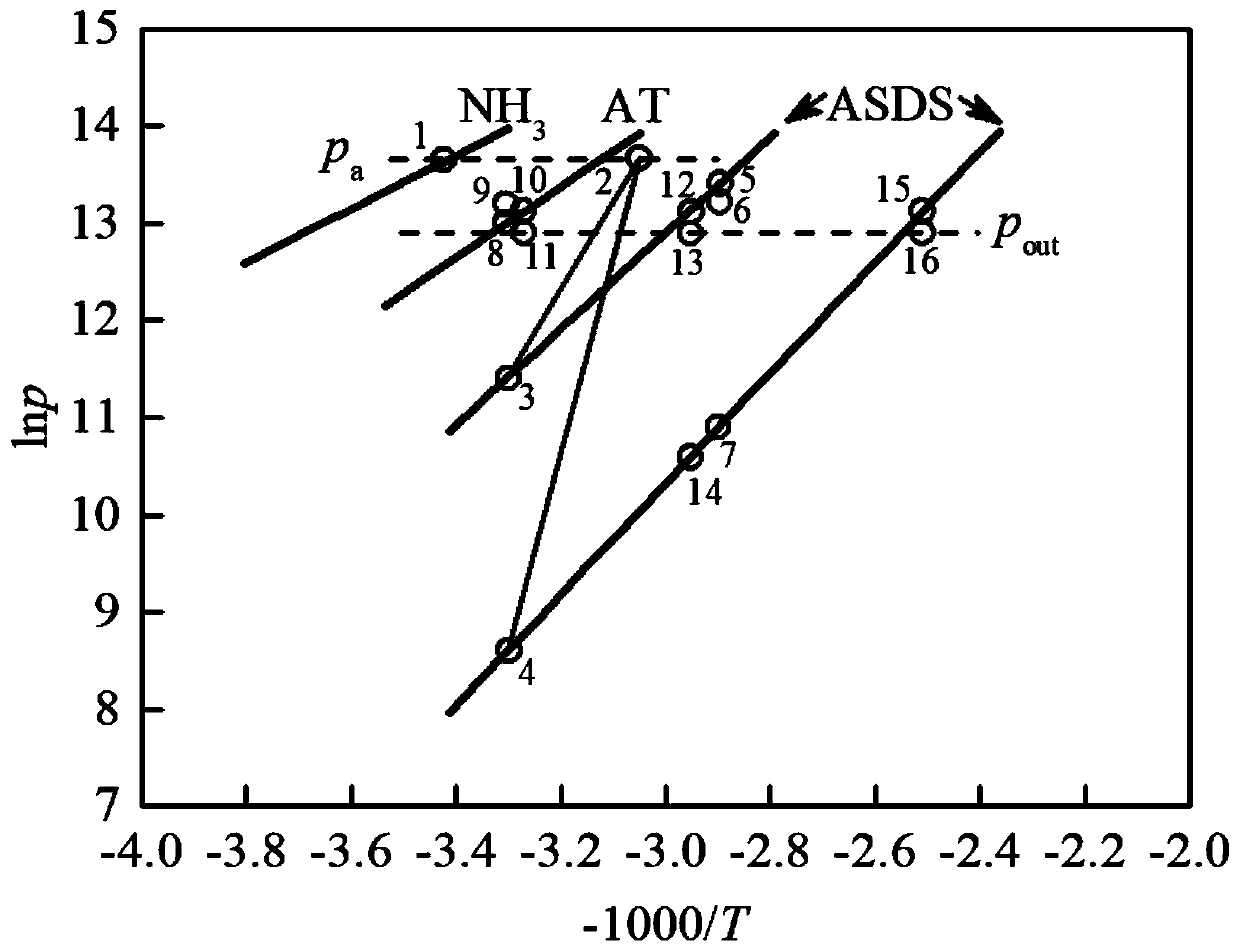

Multi-stage ammonia storage solid ammonia NOx removal system

ActiveCN111569645BImprove stabilityGuaranteed uptimeDispersed particle separationAmmonia storageFlue gas

The invention provides a multi-stage ammonia storage type solid ammonia to remove NO x The system includes an ammonia storage-exhaust unit, an ammonia transfer unit and a catalytic reactor; the flue gas is divided into two paths, one of which enters the ammonia storage-exhaust unit and then is discharged and the other merges into the catalytic reactor; the ammonia storage-exhaust unit The ammonia gas inlet and outlet are arranged on the top, and the ammonia gas outlet is connected to the ammonia transfer unit through the ammonia pipe; the ammonia transfer unit is connected to the catalytic reactor through the ammonia valve and the nozzle at the outlet of the ammonia transfer unit. The ammonia storage-exhaust unit of the present invention plays the main role of ammonia supply and ammonia volume early warning, and the ammonia transfer unit plays the role of low-temperature start-up; when the locomotive is started, the ammonia transfer unit and the catalytic reactor are connected to realize NO removal x Low-temperature start-up of the system; by raising the temperature of the ammonia storage-exhaust unit to the threshold temperature, the ammonia storage-exhaust unit and the catalytic reactor are connected to achieve stable ammonia supply during operation; the multi-halide composite adsorbent is used as the ammonia storage ‑The reactive material of the ammonia exhaust unit, when the amount of ammonia is insufficient, it can realize the early warning function of ammonia amount through multi-stage reaction switching.

Owner:SHANGHAI JIAO TONG UNIV

Dual-channel launch assembly for the phased array antenna of the relay user terminal of the launch vehicle

ActiveCN110808745BReduce front areaReduce the weight of the whole machineRadio transmissionChannel powerIsolator

The invention discloses a dual-channel transmitting assembly for a phased array antenna of a carrier rocket relay user terminal, which includes a first channel radio frequency circuit and a second channel radio frequency circuit; the first channel radio frequency circuit includes: a sequentially connected second channel radio frequency circuit A digitally controlled phase shifter for one channel, a driving amplifier for the first channel, a power amplifier for the first channel, a microstrip directional coupler for the first channel, a single-section isolator for the first channel, and a first channel connected to the microstrip directional coupler for the first channel channel detection diode; the second channel radio frequency circuit includes: a second channel digitally controlled phase shifter, a second channel drive amplifier, a second channel power amplifier, a second channel microstrip directional coupler, a second channel A single-section isolator, and a second-channel detection diode connected to the second-channel microstrip directional coupler. Compared with the single-channel phase-shifting transmitting assembly, the present invention has a compact structure, which is beneficial to reducing the front area of the phased array antenna and reducing the weight of the whole machine of the phased array antenna.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

Multi-stage ammonia storage type solid ammonia NOx removal system

ActiveCN111569645AImprove stabilityStable ammonia supplyDispersed particle separationAmmonia storageFlue gas

The invention provides a multi-stage ammonia storage type solid ammonia NOx removal system. The multi-stage ammonia storage type solid ammonia NOx removal system comprises an ammonia storage-ammonia discharge unit, an ammonia transfer unit and a catalytic reactor; flue gas is divided into two paths, one path enters the ammonia storage-ammonia discharge unit and then is discharged, and converges with the other path, and enters the catalytic reactor; the ammonia storage-ammonia discharge unit is provided with an ammonia gas inlet and an ammonia gas outlet, and the ammonia gas outlet is connectedwith the ammonia transfer unit through an ammonia pipe; and the ammonia transfer unit is connected with the catalytic reactor through a ammonia transfer unit outlet ammonia valve and a spray pipe. The ammonia storage-ammonia discharge unit plays a role in main ammonia supply and ammonia amount early warning, and the ammonia transfer unit plays a role in low-temperature starting; when a locomotiveis started, the ammonia transfer unit is communicated with the catalytic reactor, so that low-temperature starting of the NOx removal system is realized; after the temperature of the ammonia storage-ammonia discharge unit is increased to a threshold temperature, the ammonia storage-ammonia discharge unit is communicated with the catalytic reactor, so that stable ammonia supply in operation is realized; a polyhalide composite adsorbent is used as a reaction material of the ammonia storage-ammonia discharge unit, and when the ammonia amount is insufficient, an ammonia amount early warning effect can be achieved through multi-stage reaction switching.

Owner:SHANGHAI JIAO TONG UNIV

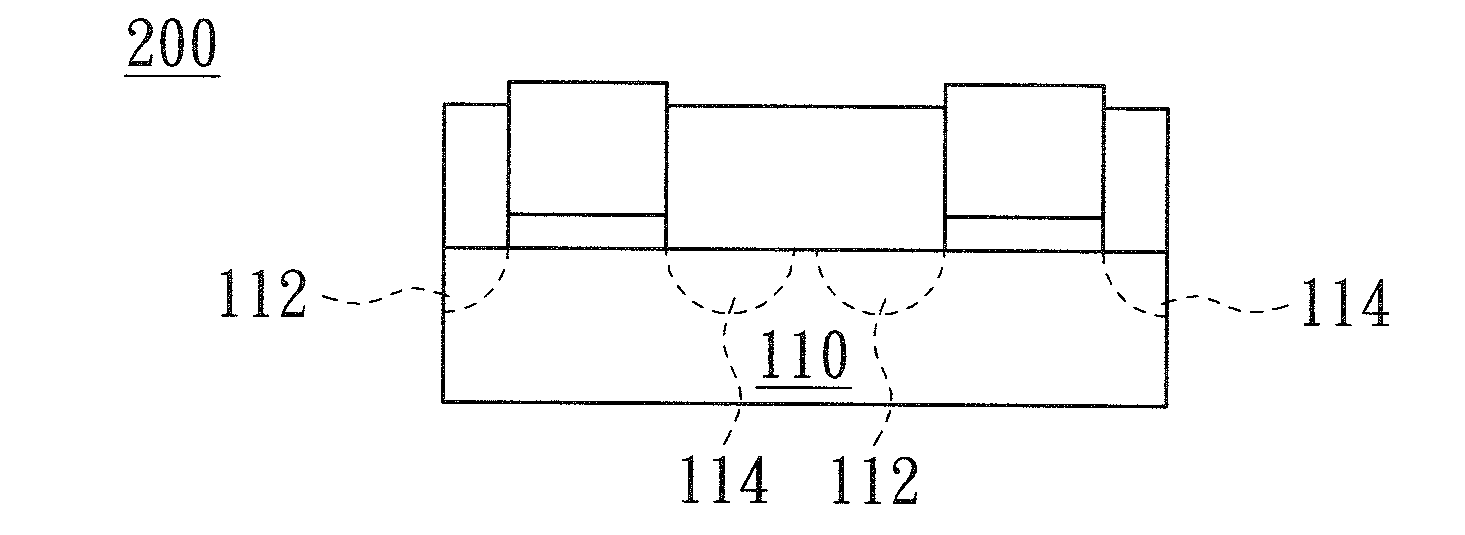

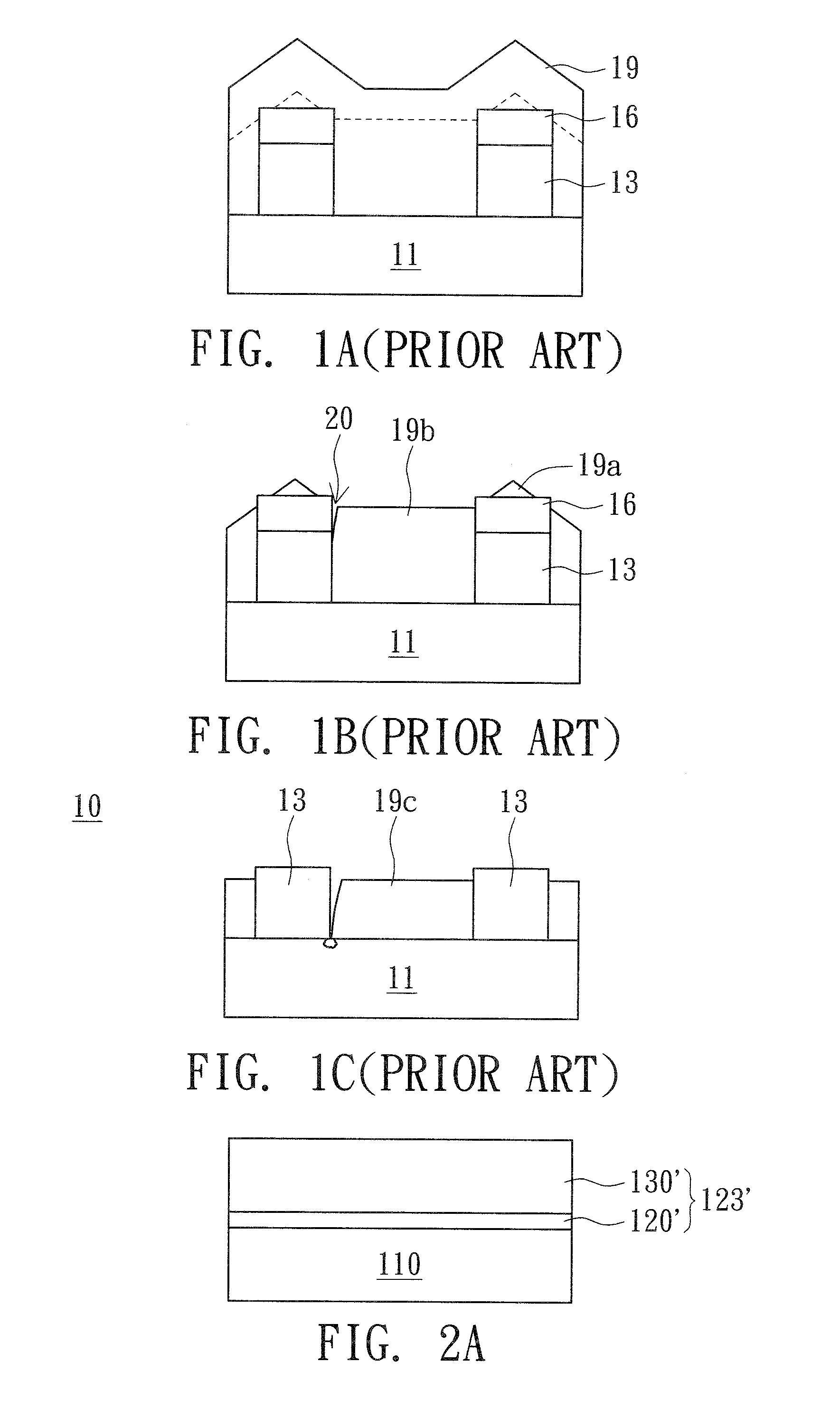

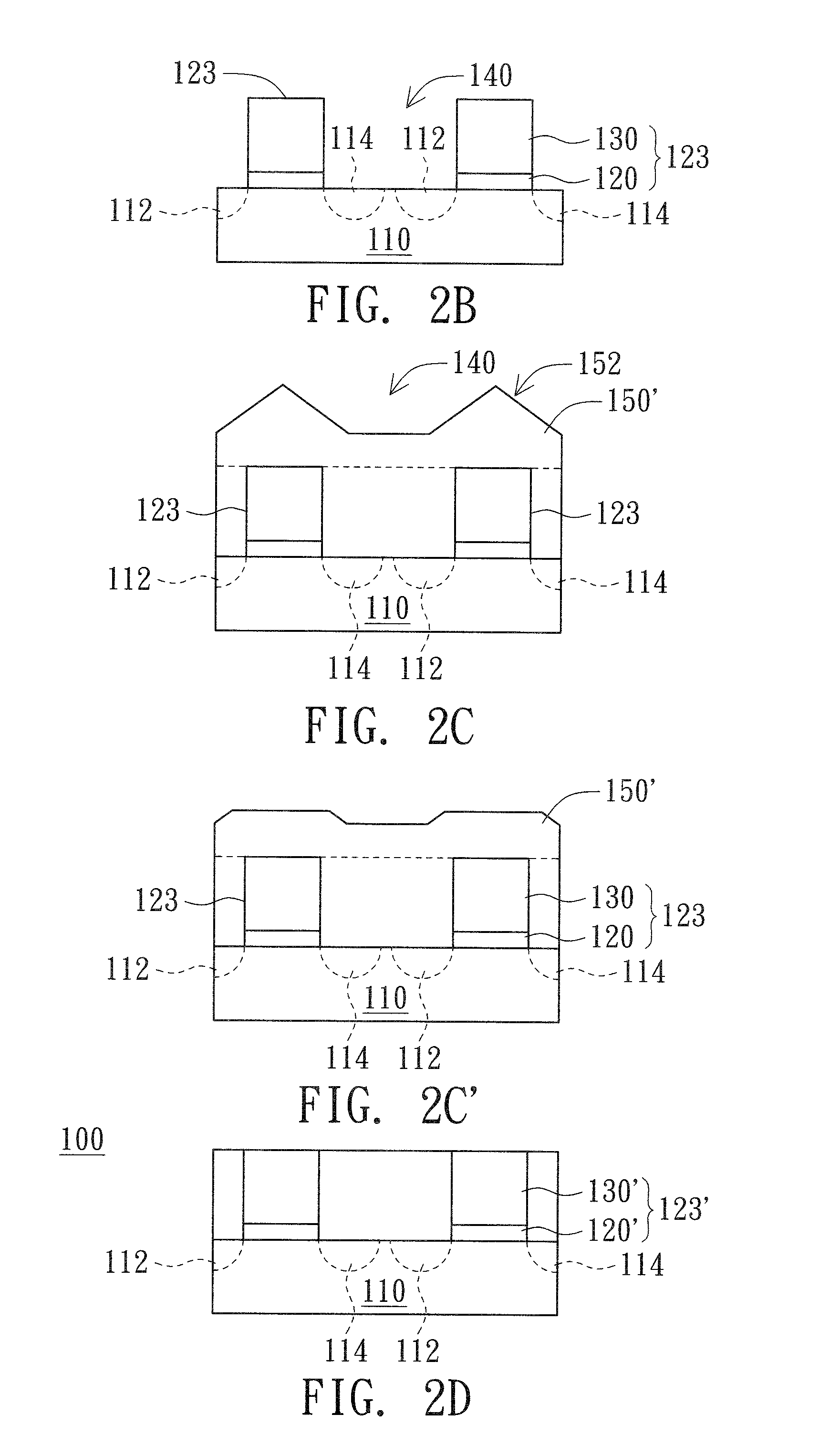

Method of forming non-volatile memory cell

ActiveUS20080194071A1Improve failure rateIncreased yieldSemiconductor/solid-state device testing/measurementSolid-state devicesCompound (substance)Engineering

A method of forming a non-volatile memory cell is provided. The method comprises: (a) providing a substrate; (b) forming a stacking structure on the substrate, the stacking structure at least comprising an oxide-nitride-oxide layer (ONO layer) and a polysilicon layer thereon; (c) patterning the stacking structure to form a plurality of separated stacking units, each two stacking units having an aperture therebetween; (d) forming a source region and a drain region buried in the substrate at two sides of the each stacking unit; (e) forming an oxide layer in the aperture and over the stacking units; and (f) performing a chemical mechanical polishing (CMP) process to remove the oxide layer over the stacking units and outside the aperture.

Owner:MACRONIX INT CO LTD

SMD solid-state capacitor and manufacturing method thereof

ActiveCN113990666AImprove failure rateAvoid damageSolid electrolytic capacitorsCapacitor housing/encapsulationCapacitorForming processes

The invention discloses an SMD solid-state capacitor and a manufacturing method thereof. A manufacturing method of an SMD solid-state capacitor comprises the following steps: putting a polymerized core package into a shell, sleeving a rubber plug on a guide pin of the core package, and controlling a gap between the rubber plug and the core package; then sealing, and controlling the top plane of a seal to be higher than the top surface of the rubber plug by a certain gap; and then aging and processing forming are carried out, wherein the processing forming comprises the steps of flattening the guide pin, assembling the base and bending the guide pin to be placed in the base groove. According to the manufacturing method, the interval between the rubber plug and the core package is controlled, and the top plane of the sealing opening is controlled to be higher than the top surface of the rubber plug by a certain gap, so that the damage to a product in the SMD forming process can be reduced, the product characteristics are stabilized, the generation of badness is reduced, and the failure rate of an application end after reflow soldering is improved.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Micromachining manufacturing method of gas sensor forced ventilation cooling and heat pump

InactiveCN102234099BReduce linearityImprove failure rateDecorative surface effectsMaterial analysis by electric/magnetic meansEngineeringGas exchange

Owner:HARBIN JIAQI TECH DEV

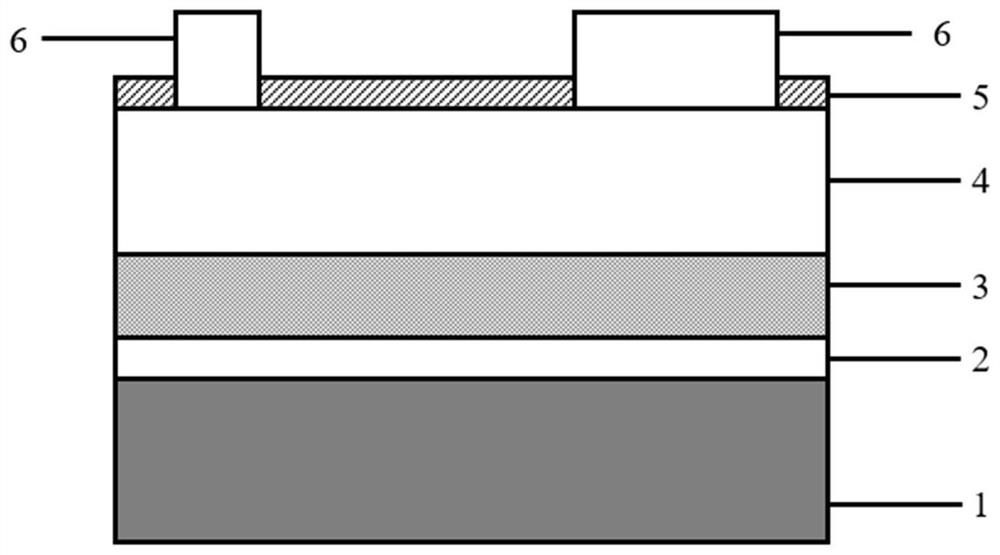

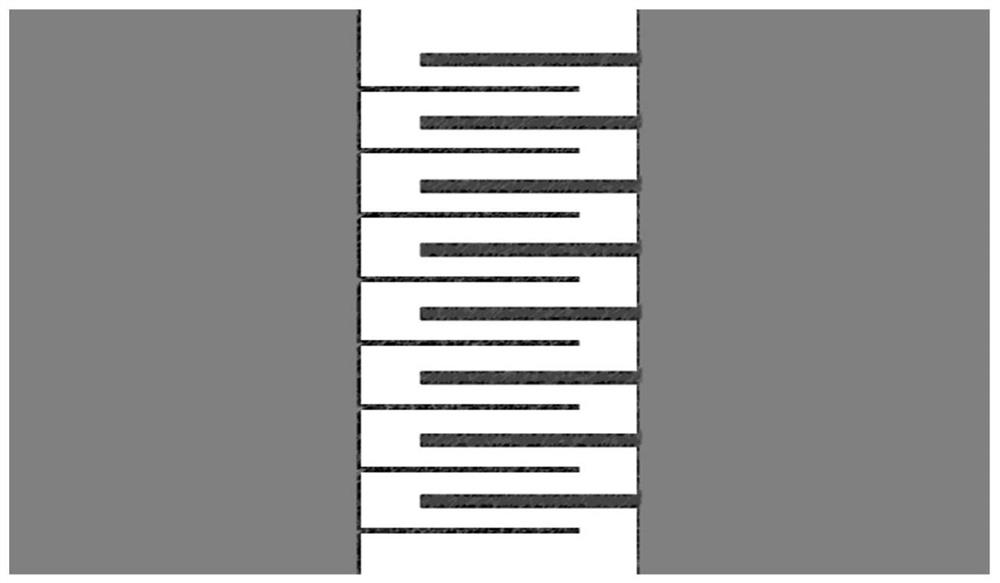

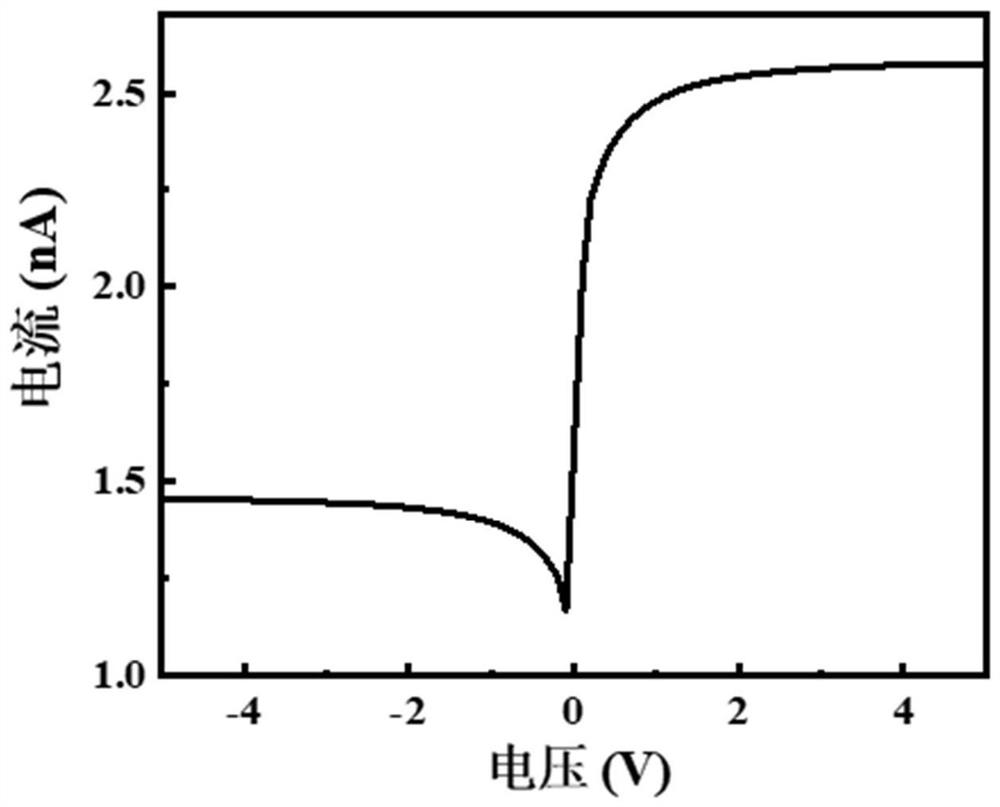

Non-polar a-surface GaN-based ultraviolet photoelectric detector and preparation method thereof

PendingCN114784123AAchieve growthSmall lattice mismatchSemiconductor devicesPhotovoltaic detectorsUltraviolet

The invention discloses a non-polar a-surface GaN-based ultraviolet photoelectric detector and a preparation method thereof. The ultraviolet photoelectric detector comprises an ultraviolet photoelectric detector epitaxial wafer, a Si3N4 passivation layer deposited on the ultraviolet photoelectric detector epitaxial wafer, and a Schottky interdigital electrode of an asymmetric MSM structure. The ultraviolet photoelectric detector epitaxial wafer comprises a non-polar a-surface AlN buffer layer, a non-polar a-surface AlxGa1-xN buffer layer with gradually changed components and a non-polar a-surface GaN epitaxial layer which are sequentially grown on an r-surface sapphire substrate, wherein x is equal to 0.2-0.8; the Si3N4 passivation layer is arranged on the non-polar a-surface GaN epitaxial layer; and the Schottky interdigital electrode penetrates through the Si3N4 passivation layer and is in direct contact with the non-polar a-surface GaN epitaxial layer on the ultraviolet photoelectric detector epitaxial wafer. According to the invention, the high-performance non-polar a-surface GaN ultraviolet photoelectric detector is realized, the dark current of the device is reduced, and the stability is improved.

Owner:SOUTH CHINA UNIV OF TECH

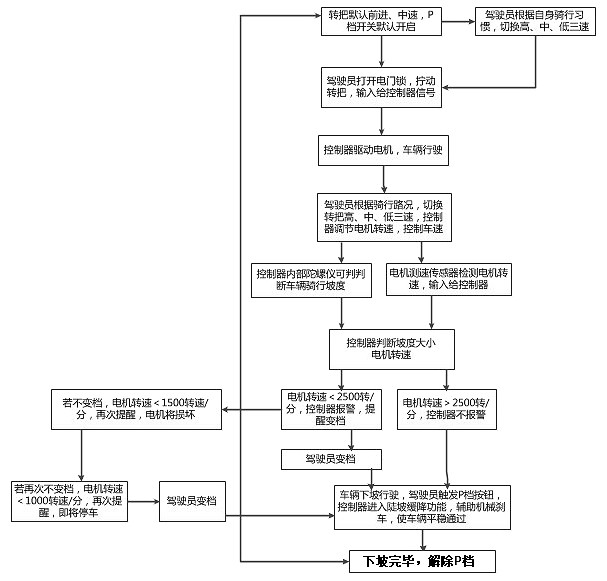

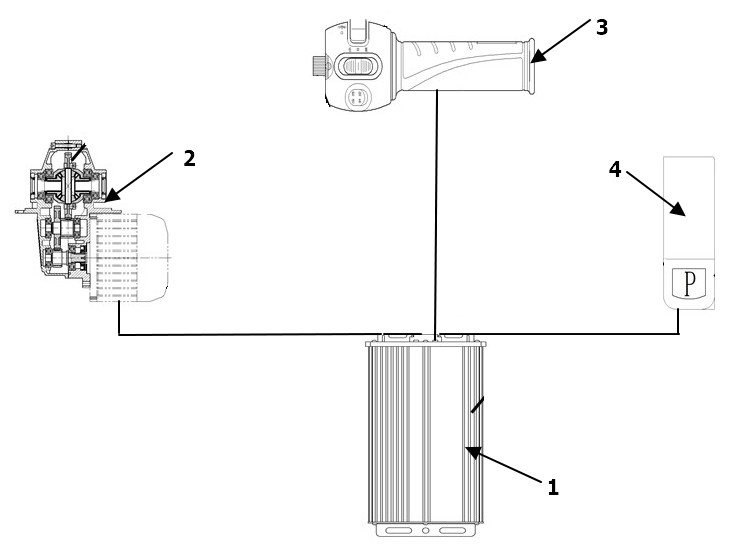

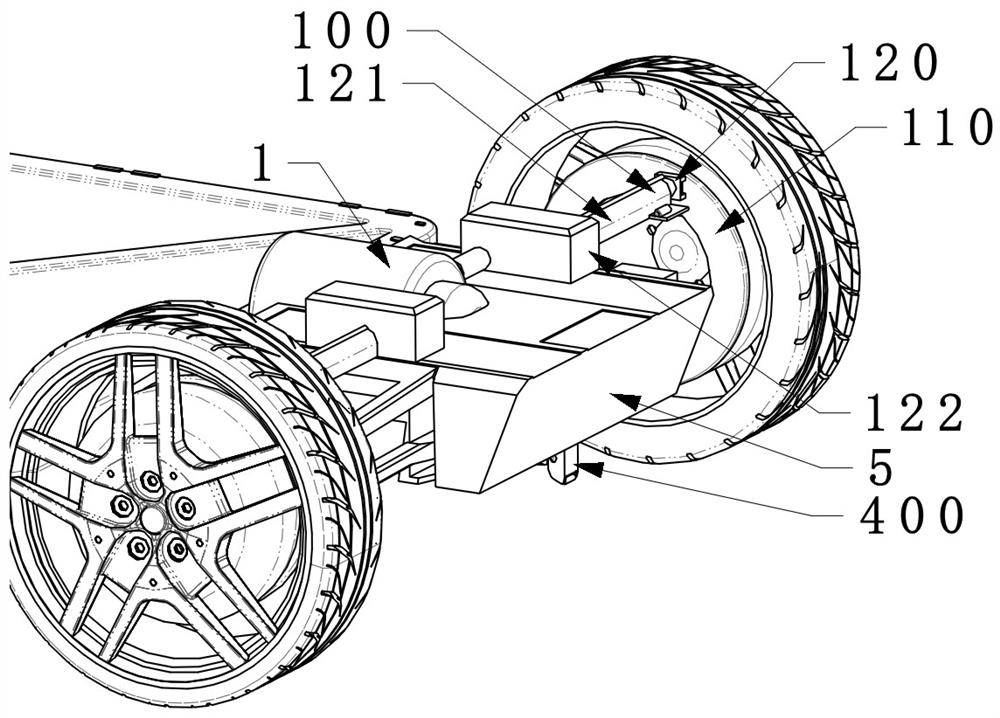

An electric vehicle power acceleration control system

ActiveCN113511079BReduce failure rateImprove failure rateAcoustic signalSpeed controllerMotor speedDriver/operator

The application discloses a power acceleration control system for an electric vehicle, including a motor, a motor speed sensor, a controller, a gearbox, a handle and a P-speed switch; the motor speed sensor signal is output to the controller, and the controller The motor speed is detected from time to time. When the motor speed is lower than 2500 rpm, the controller will output an alarm to prompt the driver to switch to a low mechanical gear; The P-gear signal is output to the controller, and the controller applies reverse resistance to the motor to assist the mechanical brake to smoothly pass through the steep slope section; it solves the high failure rate of the motor caused by the slope in the prior art when the electric vehicle is used in the mountainous area, which is easy to occur. The technical problems of brake failure and poor reliability of electric vehicles; the technical effects of low motor failure rate, reliable braking and high safety when electric vehicles are used in mountainous areas are realized.

Owner:江苏国吉电驱动科技有限公司

A method for improving the breakdown voltage of gate oxide layer of trench vdmos device

ActiveCN104779162BImprove breakdown voltageImprove failure rateSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingGate oxide

The invention provides a method for increasing breakdown voltage of a gate oxide layer of a groove-type VDMOS (Vertical Double-diffused Metal Oxide Semiconductor) device. The method comprises the following steps of providing a silicon substrate with an epitaxial layer, forming an initial oxide layer on the epitaxial layer of the silicon substrate, performing photoetching and etching, forming an active region graph on the initial oxide layer, performing ion injection, forming an active region in the epitaxial layer below the active region graph, performing the photoetching, forming a photoresist layer with a loop region graph and a gate graph, sequentially performing wet method etching and dry method etching, forming the loop region graph and the gate graph on the initial oxide layer, performing the ion injection, forming a loop region in the epitaxial layer below the loop region graph, removing the photoresist layer, forming a hard mask on the epitaxial layer and the initial oxide layer, performing the etching, forming a groove in the active region, removing the hard mask, and forming a gate above the gate graph. The method can effectively remove a damaged part on the surface of the epitaxial layer of the silicon substrate caused by operation such as the etching, so that the quality of the gate oxide layer of the device can be ensured.

Owner:FOUNDER MICROELECTRONICS INT

A method for improving the breakdown voltage of gate oxide layer of trench vdmos device

ActiveCN104681444BImprove breakdown voltageImprove failure rateSemiconductor/solid-state device manufacturingSemiconductor devicesGrid patternGate oxide

The invention provides a method for improving a breakdown voltage of a gate oxide layer of a groove-type VDMOS device. The method comprises the following steps of providing a silicon substrate with an epitaxial layer; forming an initial oxide layer on the epitaxial layer of the silicon substrate; photoetching and etching so as to form an active region pattern on the initial oxide layer; injecting ions, and forming an active region in the epitaxial layer below the active region pattern; photoetching, sequentially performing wet etching and dry etching, and forming a loop region pattern and a grid pattern on the initial oxide layer, wherein the initial oxide layer is reserved above the loop region pattern and the grid pattern; injecting ions, and forming a loop region in the epitaxial layer below the loop region pattern; forming a gate above the grid pattern. The method is capable of effectively protecting the surface of the epitaxial layer below the gate oxide layer from being damaged by processes such as etching and injection, thus obviously improving the breakdown voltage of the gate oxide layer and effectively improving an IGSS failure ratio.

Owner:FOUNDER MICROELECTRONICS INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com