Non-polar a-surface GaN-based ultraviolet photoelectric detector and preparation method thereof

An electric detector, non-polar technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of complex structure of ultraviolet photodetectors, hindering the performance of ultraviolet photodetectors, high time cost and process cost, etc., to achieve The effects of avoiding electric leakage, improving external quantum efficiency, and reducing lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for preparing a non-polar a-plane GaN-based ultraviolet photodetector, which specifically includes the following steps:

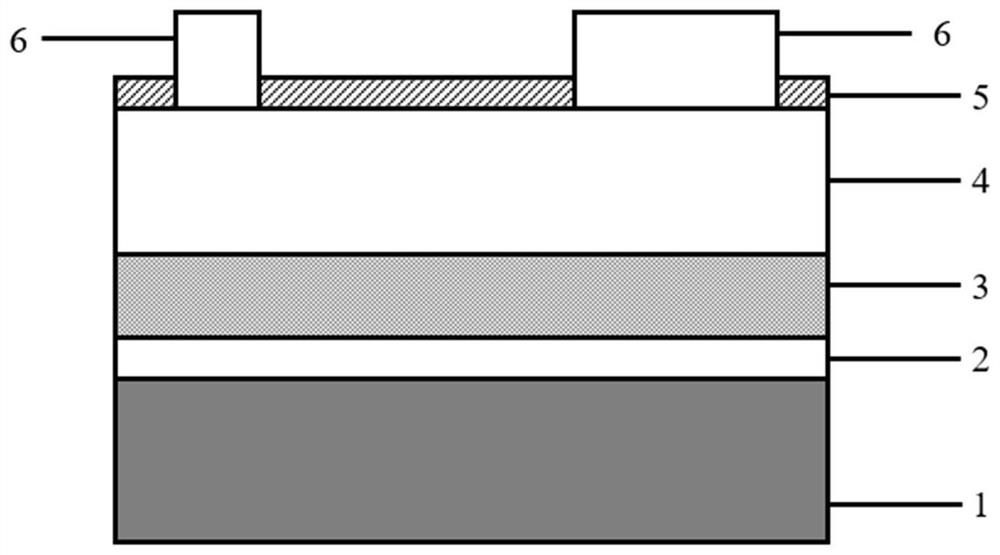

[0052] (1) If figure 1 As shown, an ultraviolet photodetector epitaxial wafer was grown on an r-plane sapphire substrate 1 by metal organic chemical vapor deposition technology, including a non-polar a-plane AlN buffer layer 2 and a non-polar a-plane Al with graded composition. x Ga 1-x The N buffer layer 3 and the non-polar a-plane GaN epitaxial layer 4, where x=0.2˜0.8.

[0053] (2) The surface of the ultraviolet photodetector epitaxial wafer obtained in step (1) is cleaned, soaked in acetone and anhydrous ethanol in sequence, and ultrasonically cleaned for 3 minutes, rinsed with deionized water after cleaning, and dried in hot high-purity nitrogen. .

[0054] (3) Using plasma-assisted chemical vapor deposition to deposit a layer of Si on the surface of the ultraviolet photodetector epitaxial wafer obtained in s...

Embodiment 2

[0066] This embodiment provides a method for preparing a non-polar a-plane GaN asymmetric MSM type ultraviolet photodetector, which specifically includes:

[0067] (1) If figure 1 As shown, an ultraviolet photodetector epitaxial wafer was grown on an r-plane sapphire substrate 1 by metal organic chemical vapor deposition technology, including a non-polar a-plane AlN buffer layer 2 and a non-polar a-plane Al with graded composition. x Ga 1-x N buffer layer 3 and non-polar a-plane GaN epitaxial layer 4, wherein:

[0068] The non-polar a-plane AlN buffer layer 2 is grown on the r-plane sapphire substrate 1 with a thickness of 120 nm;

[0069] Compositionally graded nonpolar a-plane Al x Ga 1-x The N buffer layer 3 is grown on the non-polar a-plane AlN buffer layer 2 with a thickness of 450 nm;

[0070] Non-polar a-plane GaN epitaxial layers grown on compositionally graded non-polar a-plane Al x Ga 1-x On the N buffer layer 3, the thickness is 3 μm.

[0071] (2) The surfac...

Embodiment 3

[0082] This embodiment provides a method for preparing a non-polar a-plane GaN asymmetric MSM type ultraviolet photodetector, which specifically includes:

[0083] (1) If figure 1 As shown, an ultraviolet photodetector epitaxial wafer was grown on an r-plane sapphire substrate 1 by metal organic chemical vapor deposition technology, including a non-polar a-plane AlN buffer layer 2 and a non-polar a-plane Al with graded composition. x Ga 1-x N buffer layer 3 and non-polar a-plane GaN epitaxial layer 4, wherein:

[0084] The non-polar a-plane AlN buffer layer 2 is grown on the r-plane sapphire substrate with a thickness of 200 nm;

[0085] Compositionally graded nonpolar a-plane Al x Ga 1-x The N buffer layer 3 is grown on the non-polar a-plane AlN buffer layer 2 with a thickness of 600 nm;

[0086] Non-polar a-plane GaN epitaxial layers grown on compositionally graded non-polar a-plane Al x Ga 1-x On the N buffer layer 3, the thickness is 4 μm;

[0087] (2) The surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com