SMD solid-state capacitor and manufacturing method thereof

A manufacturing method and capacitor technology, applied in the direction of capacitor manufacturing, electrolytic capacitor manufacturing, solid electrolytic capacitors, etc., can solve the problems of many defective ratios, large characteristic changes, large acting forces, etc., to reduce the occurrence of defects, stabilize product characteristics, The effect of improving the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

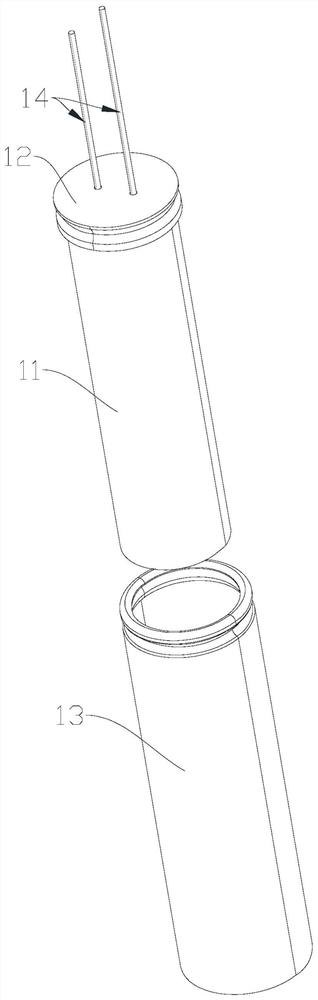

[0021] A kind of manufacturing method of SMD solid capacitor, this manufacturing method comprises the following steps:

[0022] (1) Cut the anode foil, cathode foil and electrolytic paper into preset sizes, and respectively fix and connect guide pins 14 on the anode foil and cathode foil; wind the anode foil, electrolytic paper and cathode foil into a core package 11;

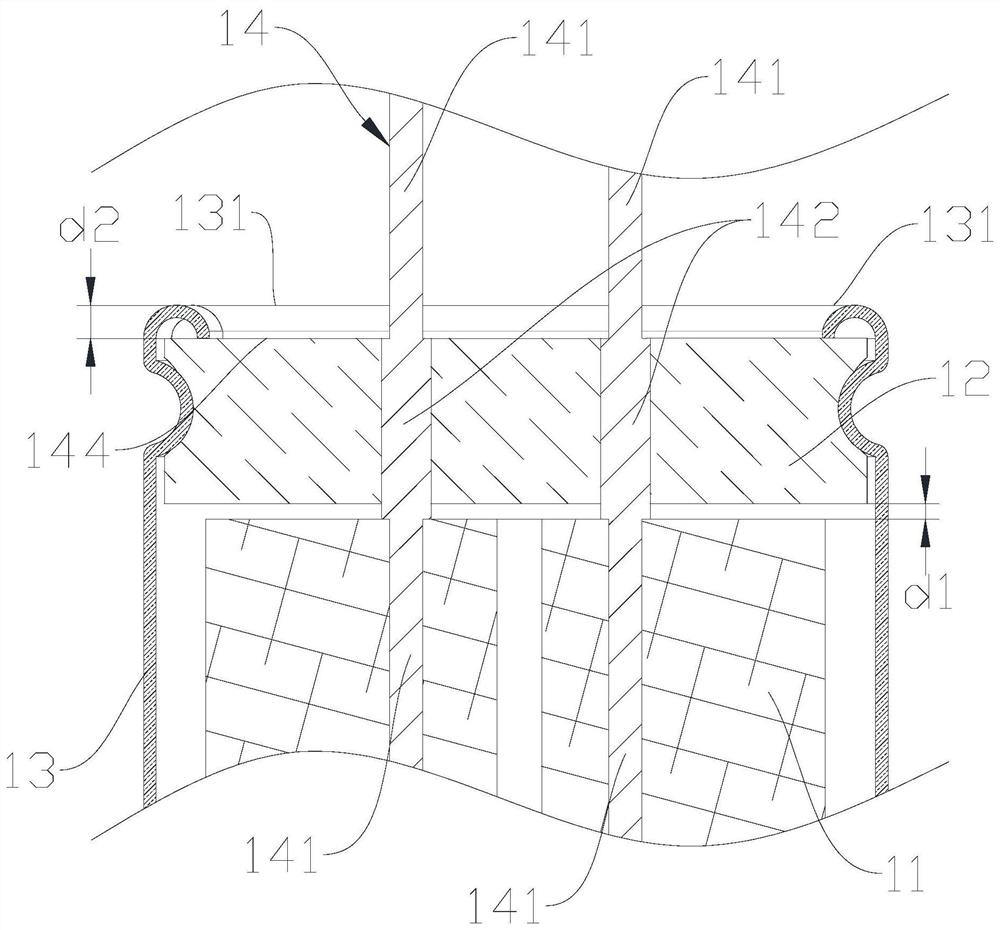

[0023] The guide pin 14 has a lead-out part 141, a support part 142 and a connecting part 143 connected in sequence, the lead-out part 141 is used to connect with the electrode foil (anode foil or cathode foil) of the core pack 11, and the support part 142 is used to socket the subsequent rubber plug 12, the connecting part 143 is used to be processed and welded, and the outer diameter of the supporting part 142 is larger than the outer diameter of the lead-out part 141 and the connecting part 143;

[0024] (2) Carrying out chemical conversion treatment on the core pack 11 to repair the oxide film on the surfac...

Embodiment 2

[0037] The preparation method of Example 2 is basically the same as that of Example 1, except that the interval is 0.3 mm and the gap is 0.6 mm.

[0038] The capacitors before molding, capacitors after molding, and capacitors after reflow soldering in Example 2 were tested for electrical characteristics, and the results were as follows:

[0039]

Embodiment 3

[0041] The preparation method of Example 3 is basically the same as that of Example 1, except that the interval is 1.0 mm and the gap is 0.3 mm.

[0042] The electrical characteristics of the capacitor before molding, the capacitor after molding and the capacitor after reflow soldering in Example 3 were tested for electrical characteristics, and the results are as follows:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com