Coil assembly structure and magnetoelectric crankshaft speed sensor

A technology of coil components and coils, applied in coils, transformers/inductor coils/windings/connections, circuits, etc., can solve problems such as impracticality, increased process difficulty and cost, to prevent product failure, reduce the risk of mechanical damage, The effect of increasing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary, and is not intended to limit the scope of the present invention and its application.

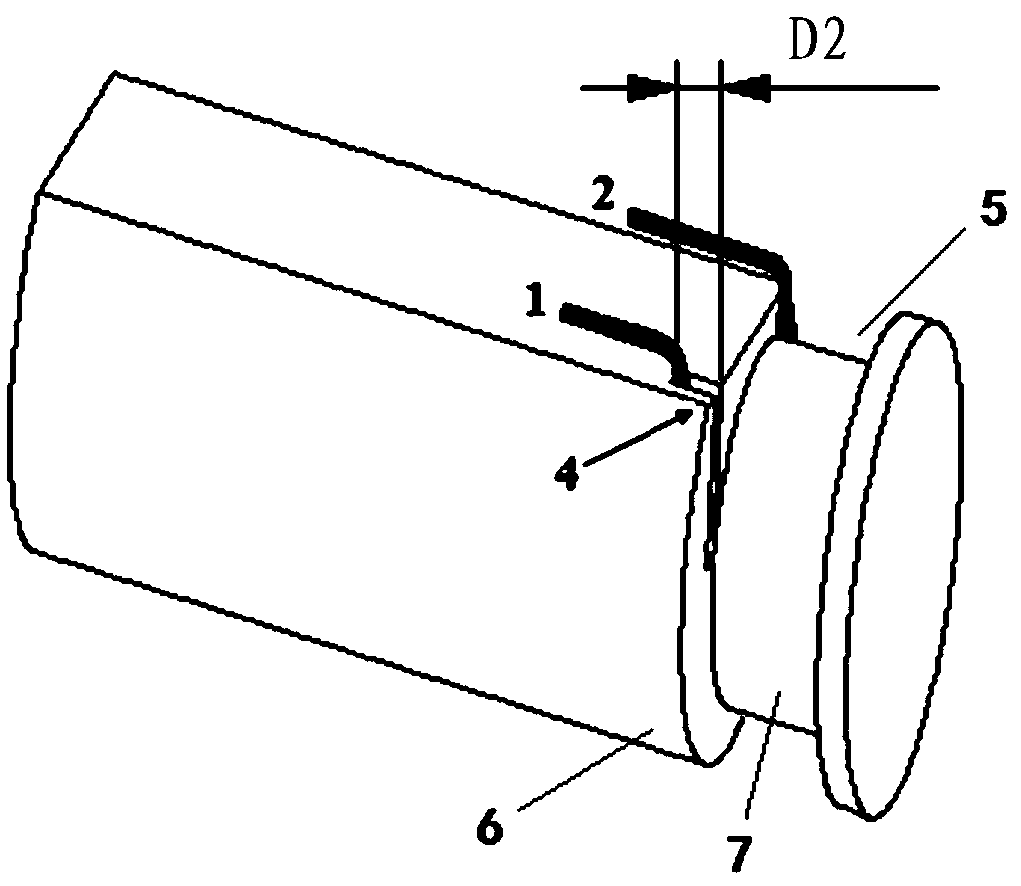

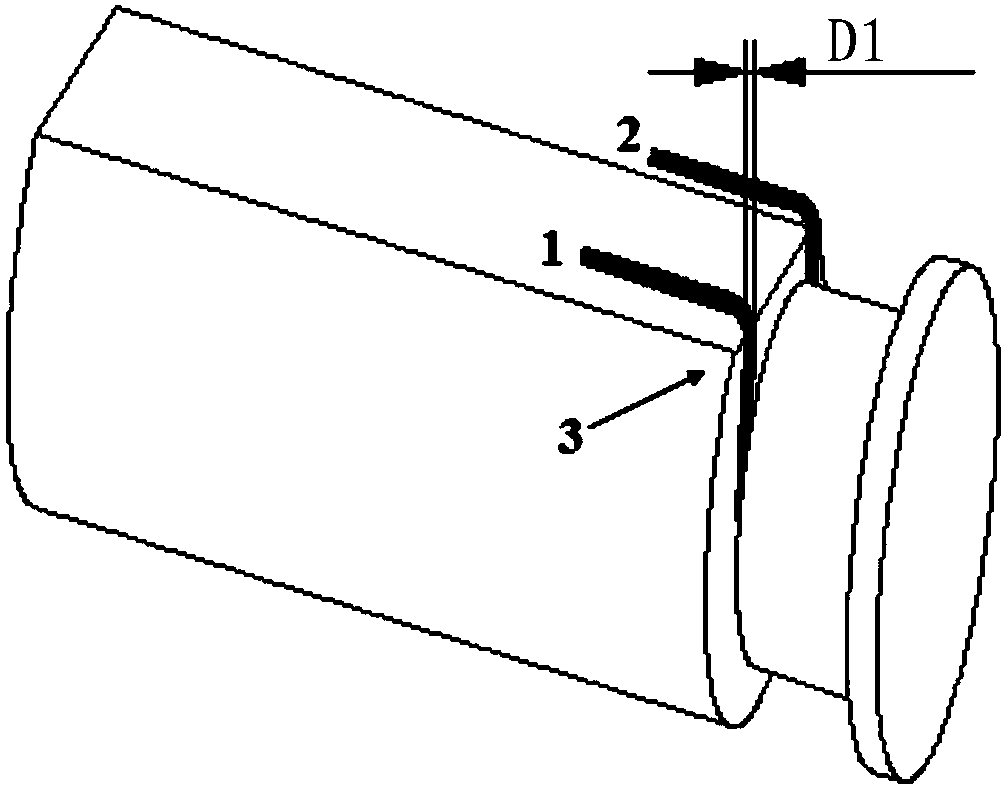

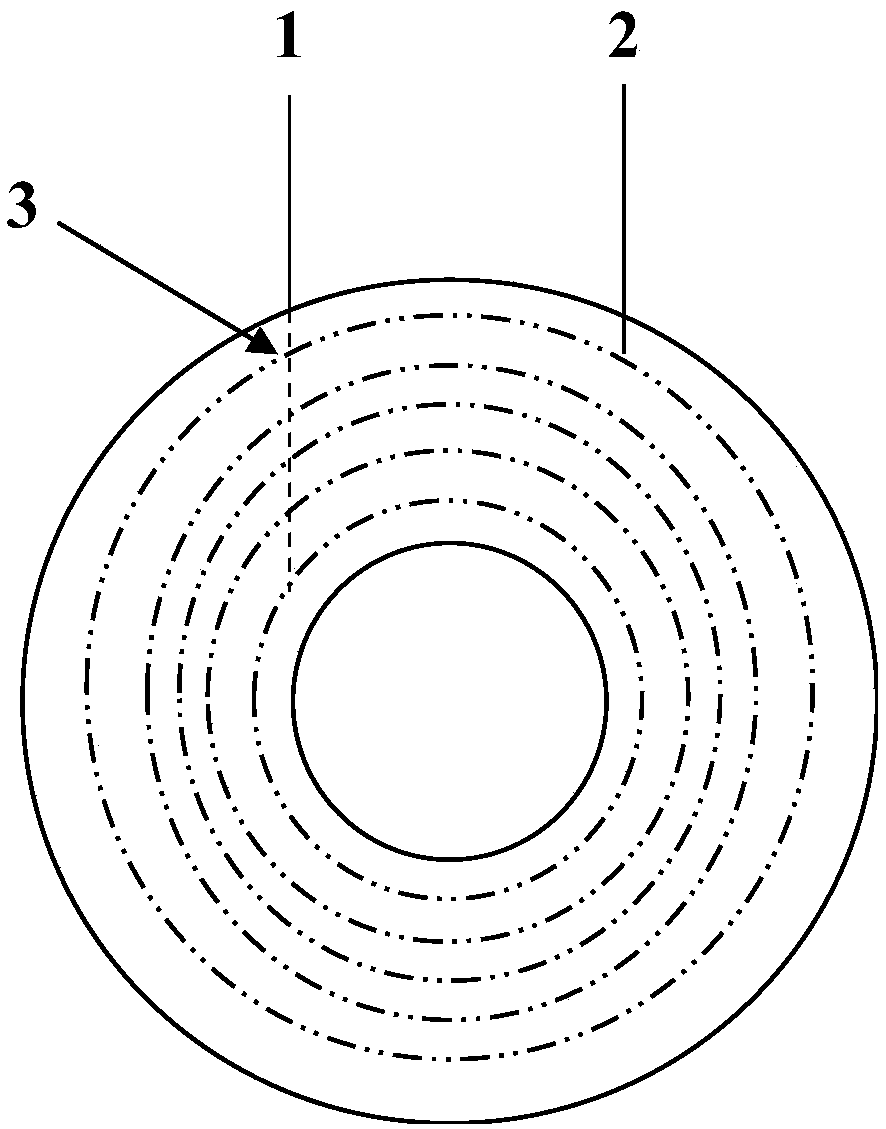

[0031] See image 3 In one embodiment, a coil assembly structure includes a coil bobbin 6 and a coil 7. The coil bobbin 6 has a winding groove 5, and the coil 7 is wound in the winding groove of the coil bobbin 6. In 5, the side wall of the winding groove 5 is provided with a lead groove 4 recessed to the outside, and the lead groove 4 extends from the winding groove 5 outward to the surface of the coil bobbin 6, for example, to On the upper plane of the coil bobbin 6, the incoming wire 1 of the coil 7 is filled into the recess of the lead groove 4, and enters the winding groove 5 along the lead groove 4, so that the coil 7 enters There is at least a separation distance between the wire 1 and the outer winding of the coil 7 caused by fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com