Combined shear connector for corrugated steel web and corrugated steel base plate and construction method

A corrugated steel web and combined technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of uncompacted steel-concrete joints, affecting the durability of the structure, and difficult vibration, etc., to achieve the overall mechanical performance Good, simple processing and manufacturing, convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

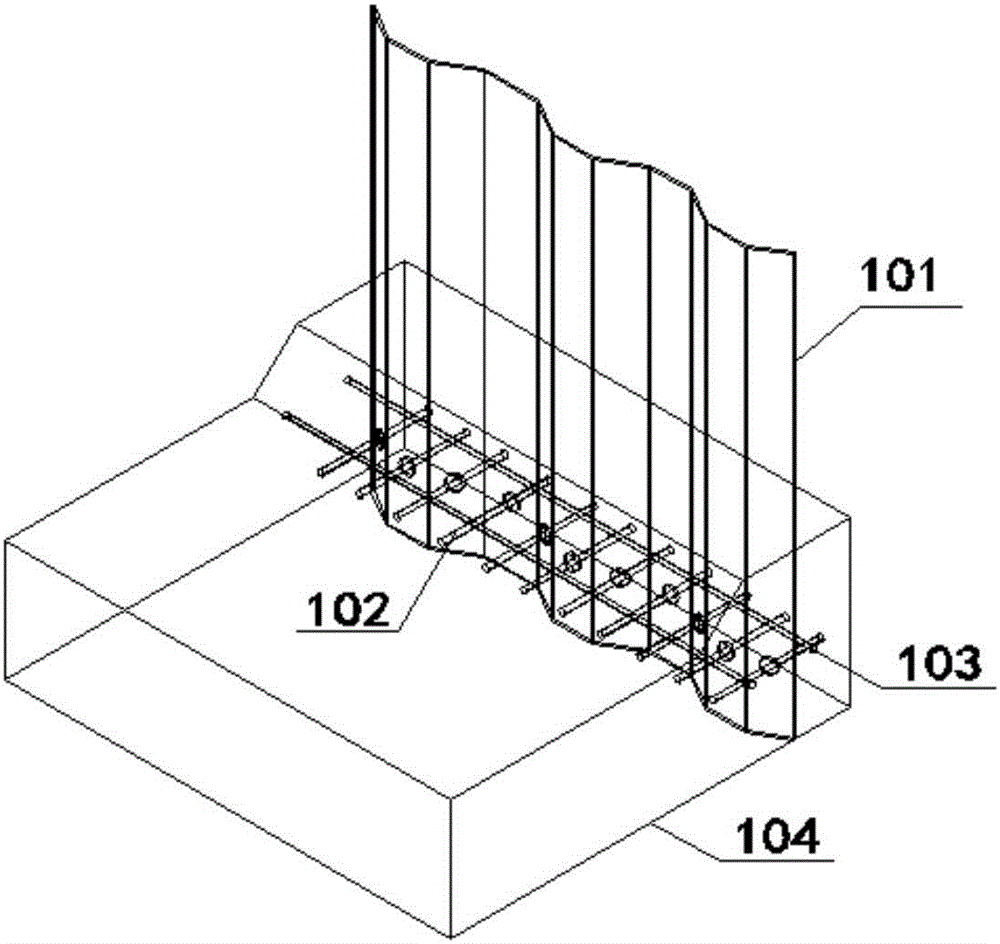

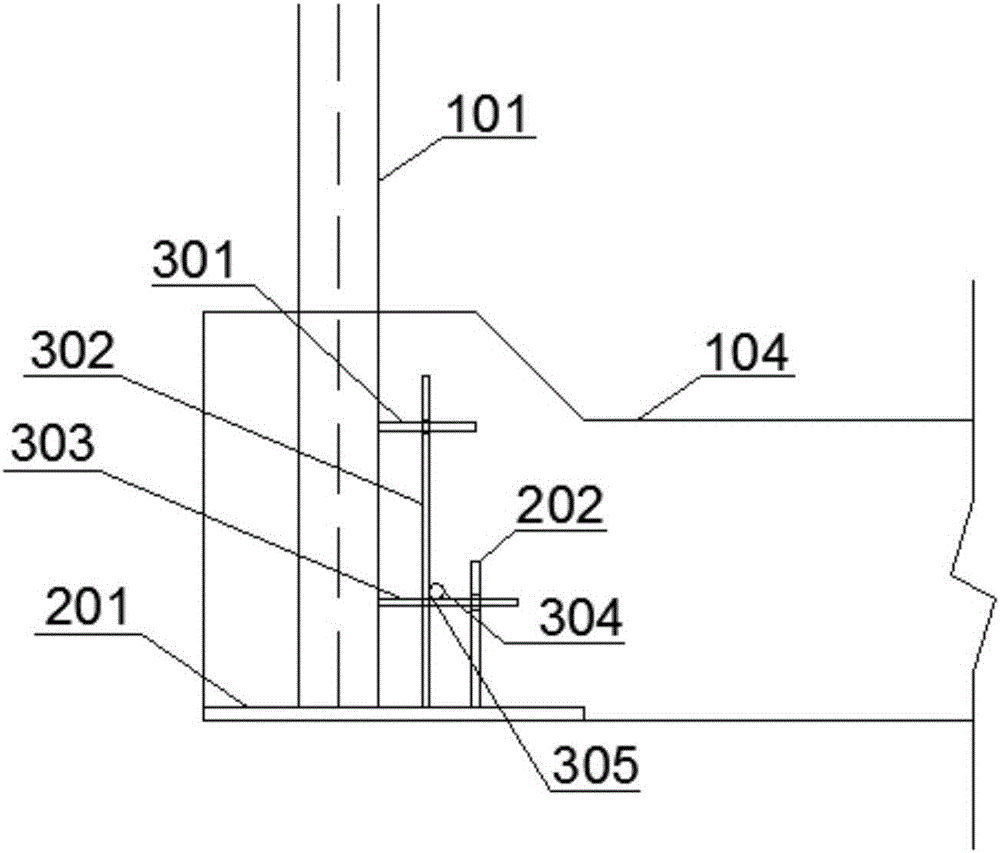

[0039] combine figure 1 As shown, the traditional embedded shear connection key is mainly composed of corrugated steel web 101 , through steel bar 102 and connecting steel bar 103 . Since the corrugated steel web 101 is integrally embedded, and the bottom is connected to the concrete floor 104 through the through steel bars 102, the overall connection and force performance are poor.

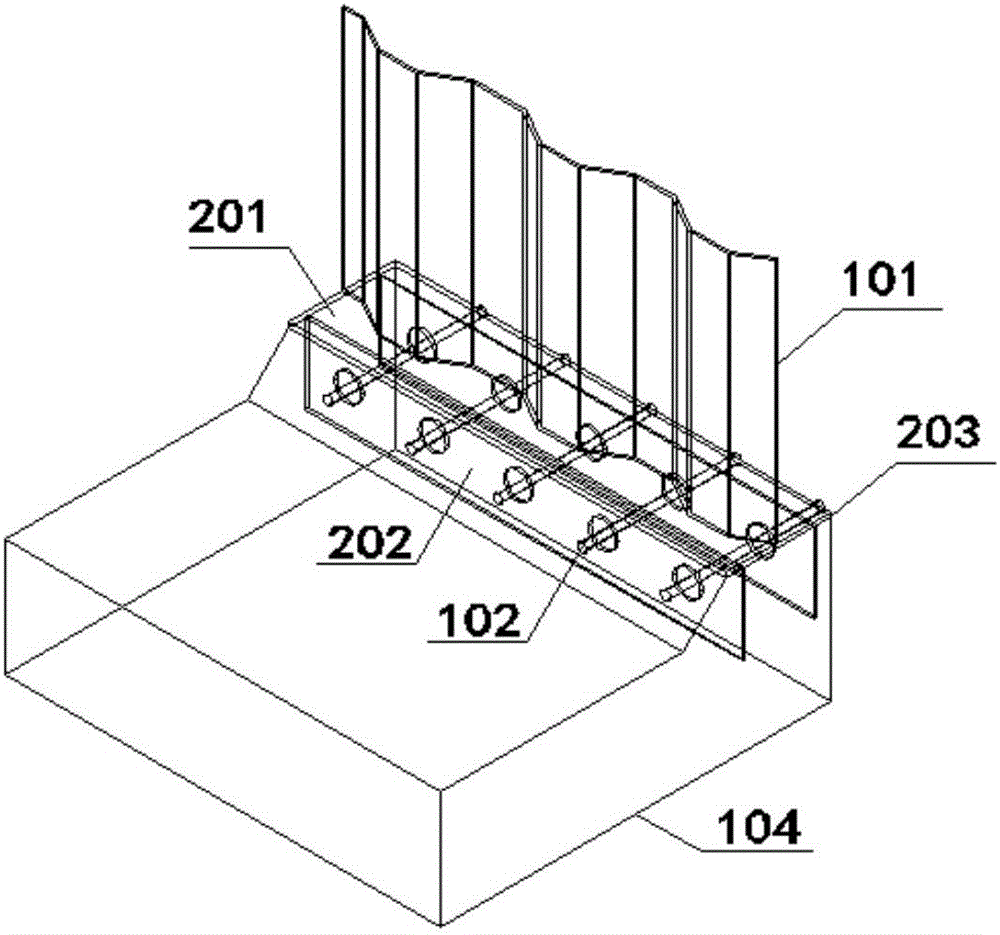

[0040] combine figure 2 As shown, the traditional flange-type shear key is mainly composed of corrugated steel web 101 , lower flange steel plate 201 , strip steel plate 202 , and through steel bar 102 . During the base plate construction, the lower flange steel plate 201 is located on the top of the shear key. After the base plate is molded, it is difficult to pour concrete and vibrate due to the obstruction of the lower flange steel plate 201, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com