Composite muffler for diesel generating set

A diesel generator set and composite technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of large volume, narrow muffler frequency band of the first-stage muffler, no heat insulation, etc. Function, the effect of low transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

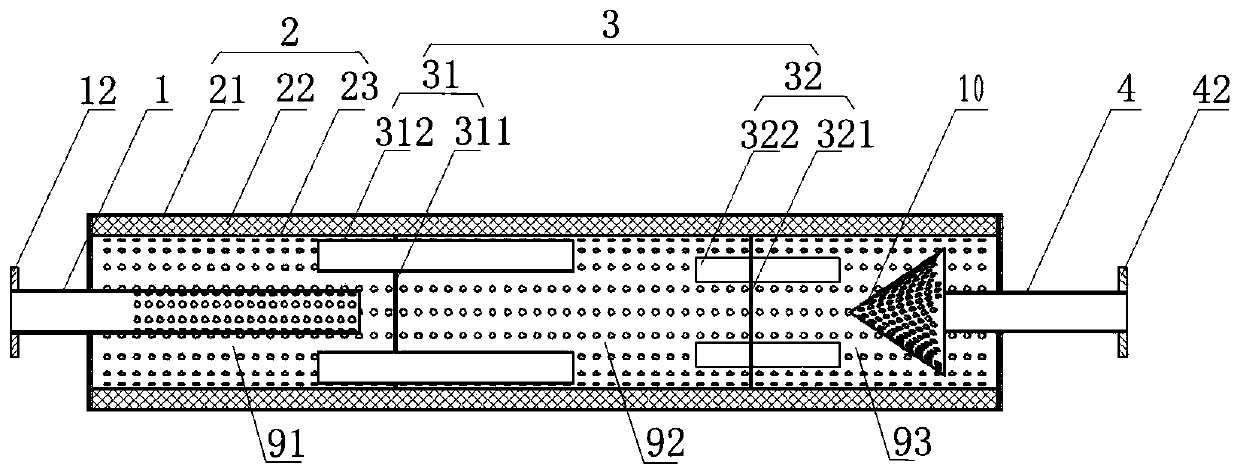

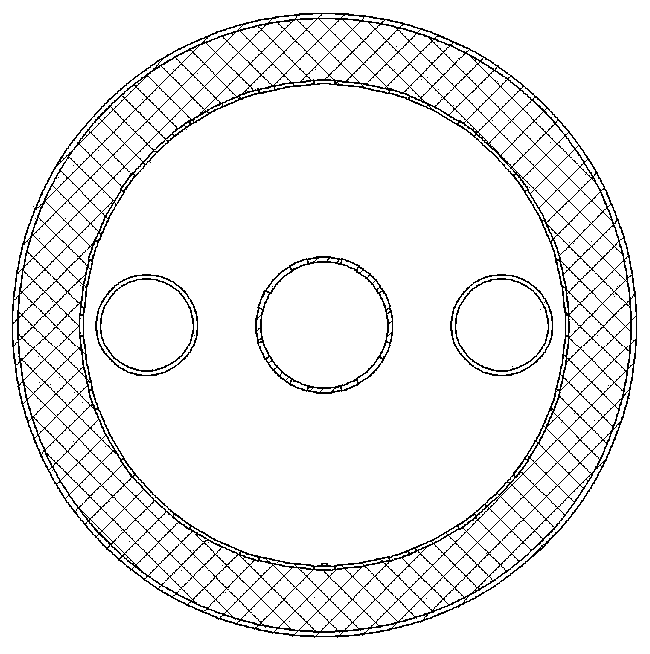

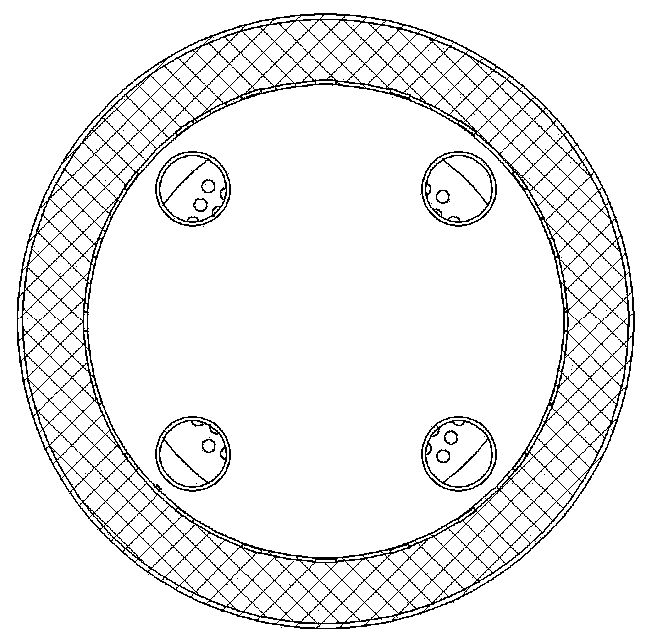

[0026] A composite muffler for a diesel generator set, comprising an intake pipe, a resistive noise reduction structure connected in series with the intake pipe, a resistive noise reduction structure arranged inside the resistive noise reduction structure, and an outlet pipe connected in series with the resistive noise reduction structure The air pipe, the resistive sound attenuation structure is composed of the muffler shell, the sound absorbing material and the resonant perforated plate in order from outside to inside.

[0027] In the resistive noise reduction structure, the resonant perforated plate not only plays a supporting role, but also is a resonance noise reduction structure to enhance the acoustic performance of the muffler; the energy is absorbed through the sound-absorbing material, and the middle and high-frequency noise is absorbed and silenced through the sound-absorbing material. The resonant perforated board has perforations, and the noise reaches the sound-ab...

Embodiment 2

[0040] On the basis of Embodiment 1, this embodiment proposes a preferred structure.

[0041] The length of the first-level inner cannula located in the expansion chamber I is one quarter of that of the expansion chamber I, and the length of the first-level inner cannula located in the expansion chamber II is one-half of the expansion chamber II one;

[0042] The length of the secondary internal cannula located in the expansion chamber II is 1 / 4 of the expansion chamber II, and the length of the secondary internal cannula located in the expansion chamber III is 1 / 2 of the expansion chamber III one.

[0043] Compared with the technical solution in Example 1, the technical solution provided in this example belongs to a preferred solution in Example 1, so that the expansion ratio design among the expansion chamber I, expansion chamber II and expansion chamber III is It is more reasonable, the transmission loss effect is lower, and the sound absorption effect is better.

Embodiment 3

[0045] On the basis of all the foregoing embodiments, in order to further improve the sound absorption effect, this embodiment provides an improved technical solution.

[0046] An acoustic spike is added to the pipe head of the outlet pipe located inside the expansion chamber III. The chisel is welded with the exhaust pipe, and the chisel adopts a cone structure. This structure makes the flow resistance of the air flow lower than that of the chisel, and can effectively absorb the middle and high frequency noise; the cone surface of the chisel There are a plurality of through holes for exhaust, and the opening ratio of the through holes is designed according to the exhaust characteristics of the diesel engine; the sound wedge is filled with stainless steel wire, which can reduce the exhaust smoke and enhance the environmental protection of the muffler.

[0047] In all the above-mentioned embodiments, the pipeline of the air inlet pipe located inside the expansion chamber I is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com