A swash plate hydraulic plunger motor or pump for submersion in water

A hydraulic plunger motor and swash plate type technology, applied in the hydraulic field, can solve the problems of water pouring into the hydraulic plunger motor or the inner cavity of the pump, high manufacturing and maintenance costs, complex device structure, etc., so as to reduce the axial The effect of reducing the size, reducing the use and maintenance cost, and simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

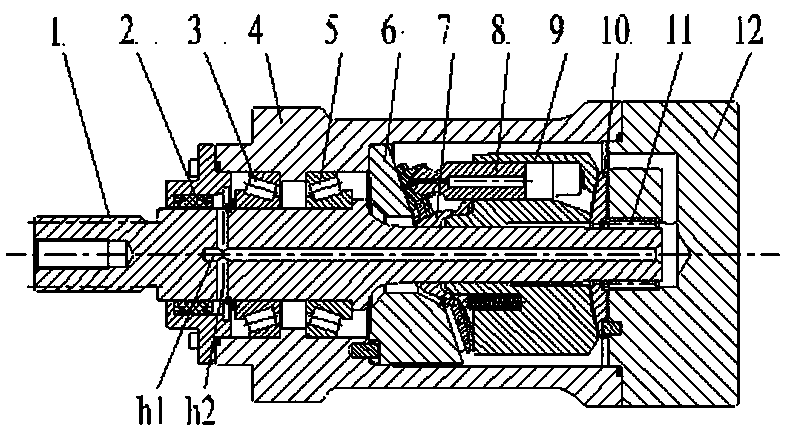

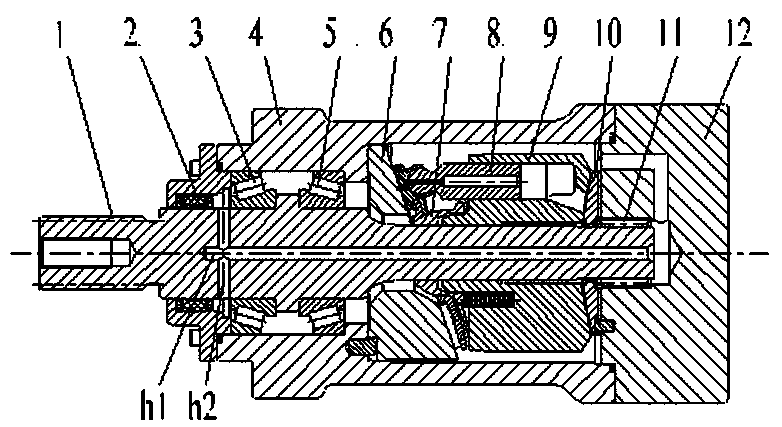

[0025] The specific implementation, features and functions of a swash plate hydraulic plunger motor or pump for submersion in water according to the patent of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0026] see Figure 1-2 , a swash plate hydraulic plunger motor or pump used submerged in water, including a main shaft 1, a rotary seal 2, a housing 4, a swash plate 6, a plunger return mechanism 7, a plunger 8, a cylinder body 9, a flow distribution The disc 10 and the end cover 12 are characterized in that: the main shaft 1 is supported by at least three coaxially installed bearings: bearing A3, bearing B5 and bearing C11, and at least two of the three bearings are radial thrust bearings , and the installation directions of the two radial thrust bearings are opposite.

[0027] Two of the three bearings are installed near the extended end of the main shaft 1 and between the rotary seal 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com