Quick switch blind plate for preventing stagnant water and corrosion

A fast switch and anti-water technology, which is applied in the direction of pressure vessels, pipes/pipe joints/fittings, fixed-capacity gas storage tanks, etc., can solve the problem of small soil impurities falling into and accumulating, unable to pry the lock ring, and accumulating rainwater, etc. problem, to achieve the effect of good dredging and drainage of accumulated water, easy and labor-saving opening operation, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

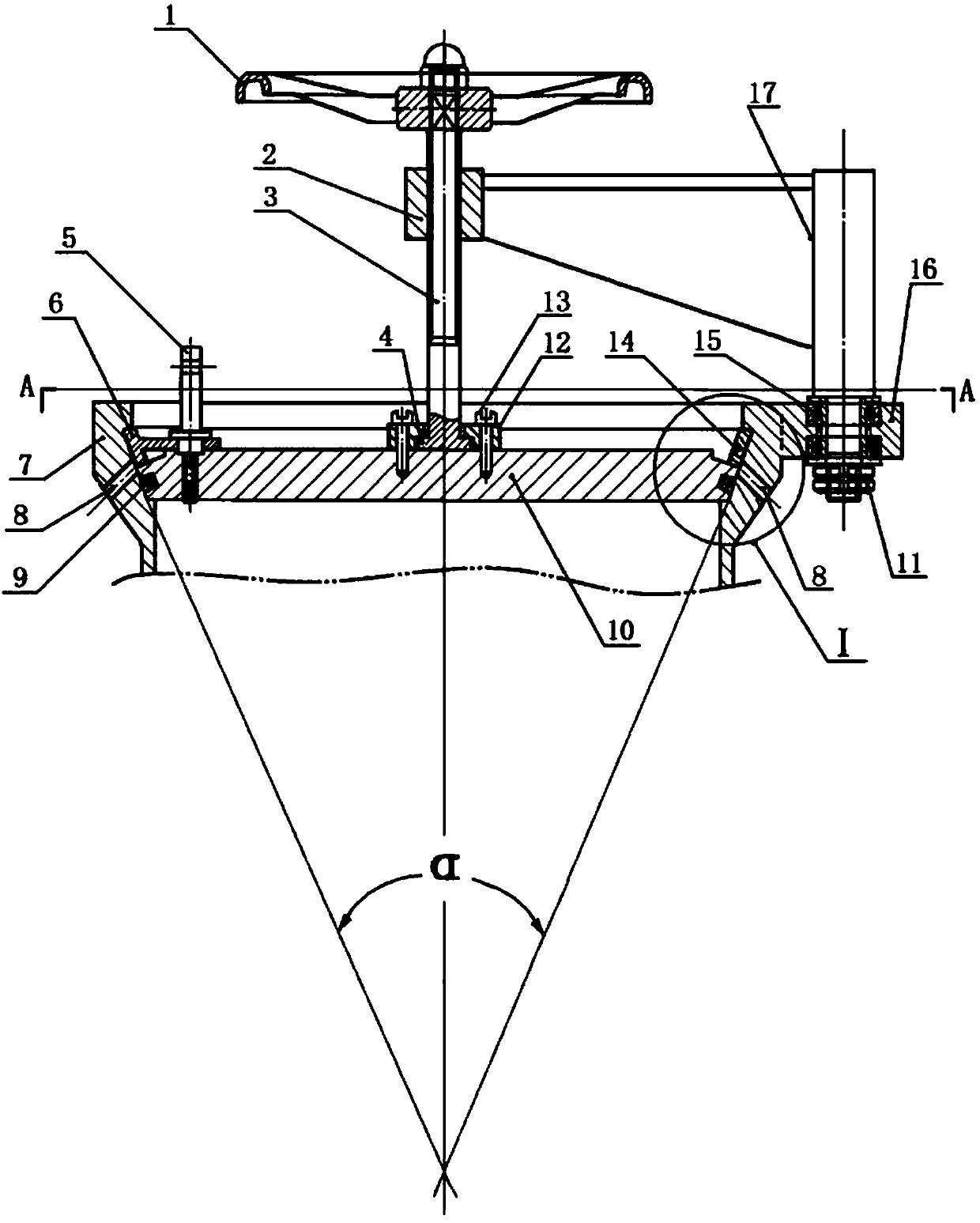

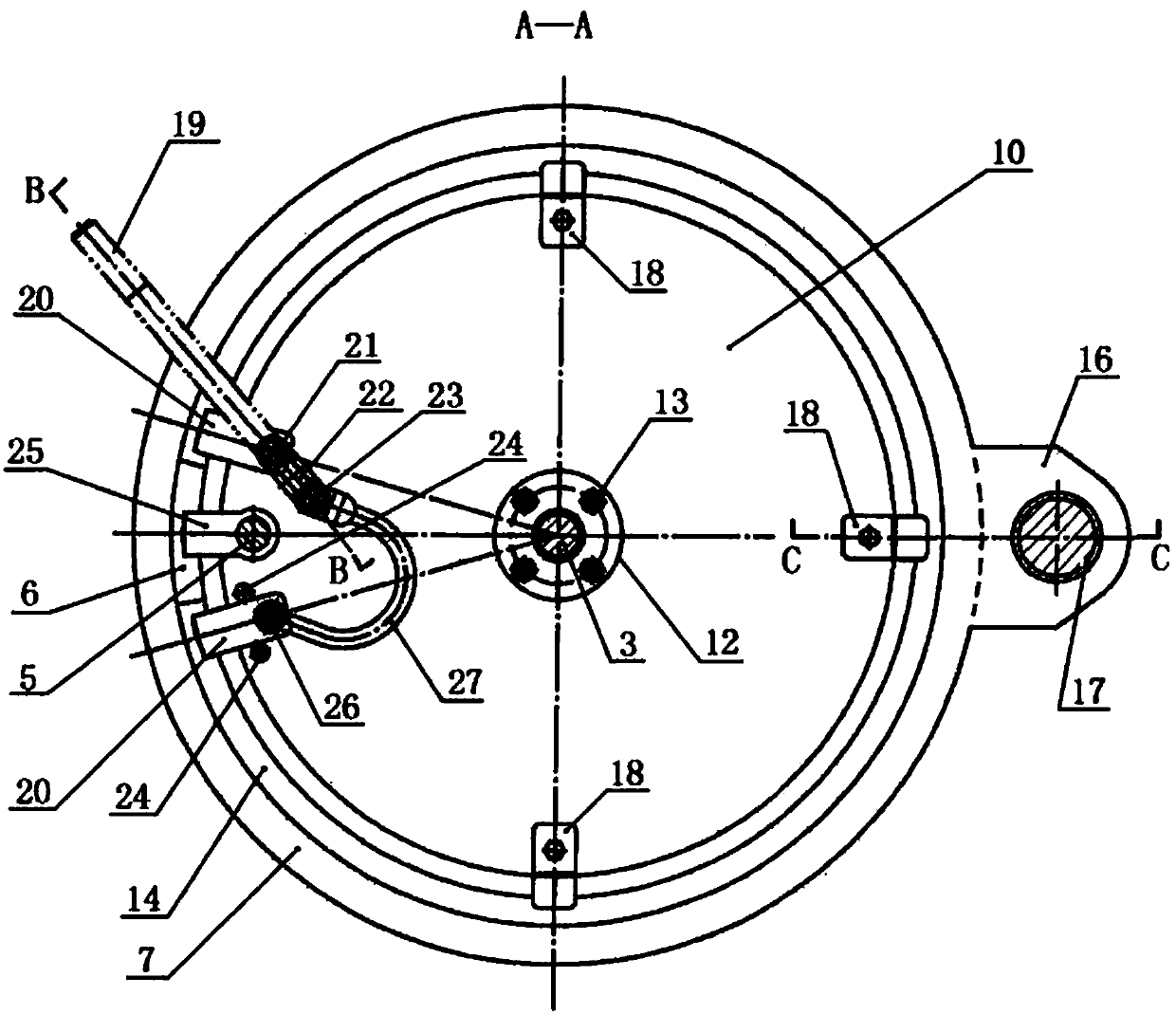

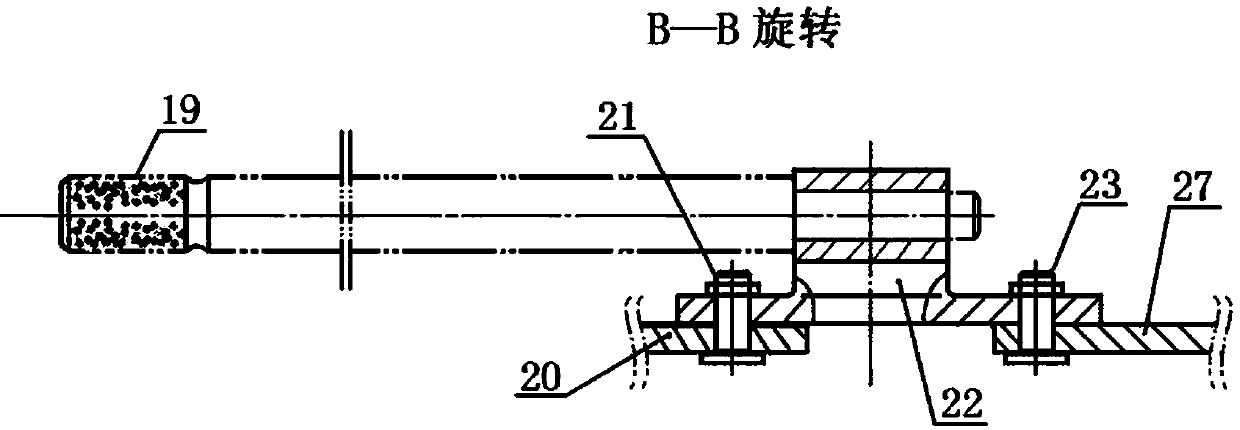

[0029] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0030]The present invention proposes a fast switch blind plate that prevents stagnant water and corrosion. It is mainly composed of a flange blind seat 7, a supporting rocker arm 17 installed on the flange blind seat 7, a flange blind cover 10, a lifting screw 3, and a locking Ring 14, insurance ring 6, elastic lock rib 27, rotating arm 22 constitute. The support rocker arm 17 is tightly fixed and installed on the side ear support 16 on one side of the flange blind seat 7 by a set nut 11, and a bearing 15 is equipped on the rotating shaft of the support rocker arm 17, which can greatly improve the support The rotating flexible performance of rocking arm 17. A hand wheel 1 is installed on the top of the lifting screw 3, and a convex plate 4 is arranged at the bottom of the lifting screw 3. The bottom cover 12 mounted on the lifting screw 3 is press-fitted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com