Sealing device used for micro rotor engine

A rotary engine and sealing device technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem of easy wear of radial sealing sheets, increase life and efficiency, reduce wear and eccentric wear, and reduce pressure. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

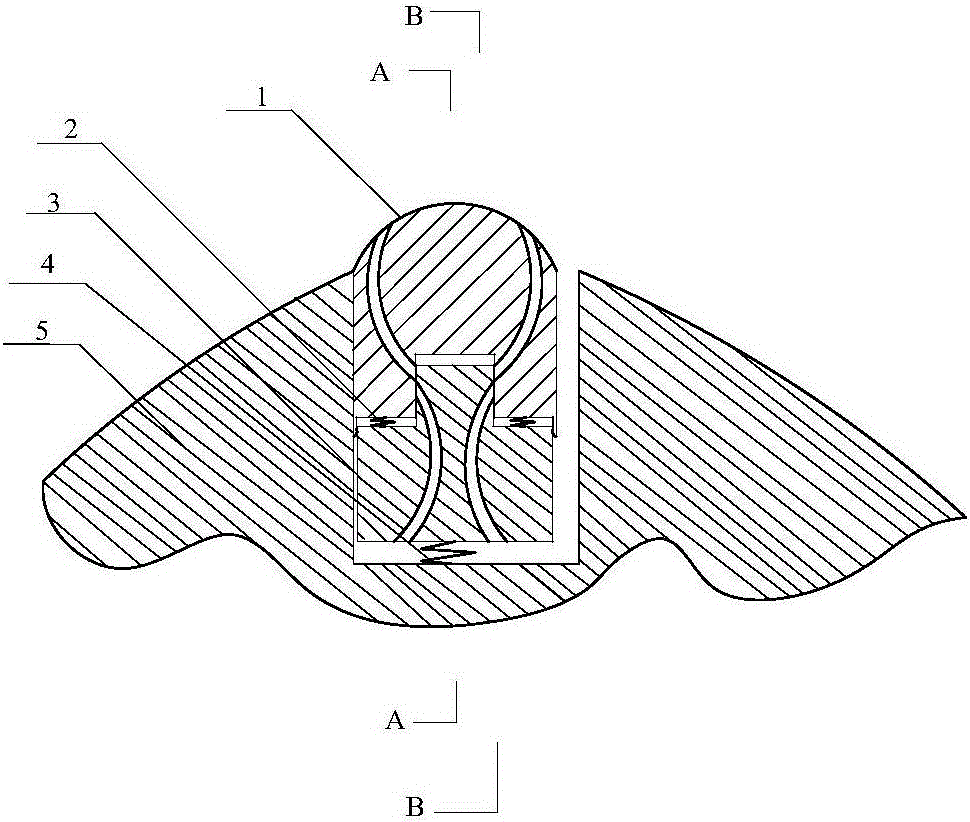

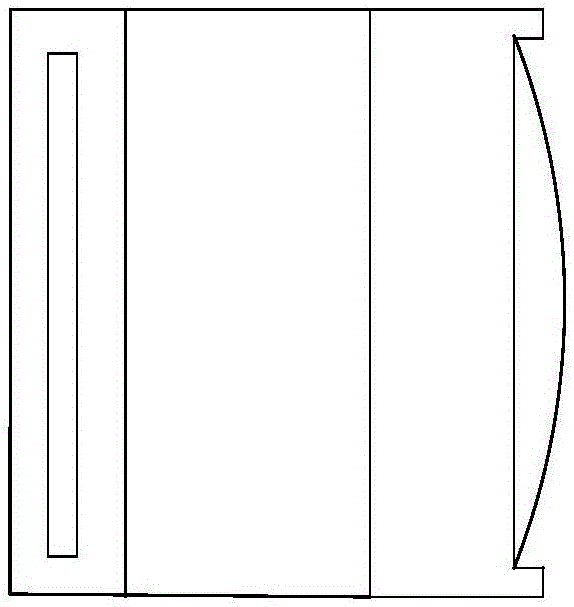

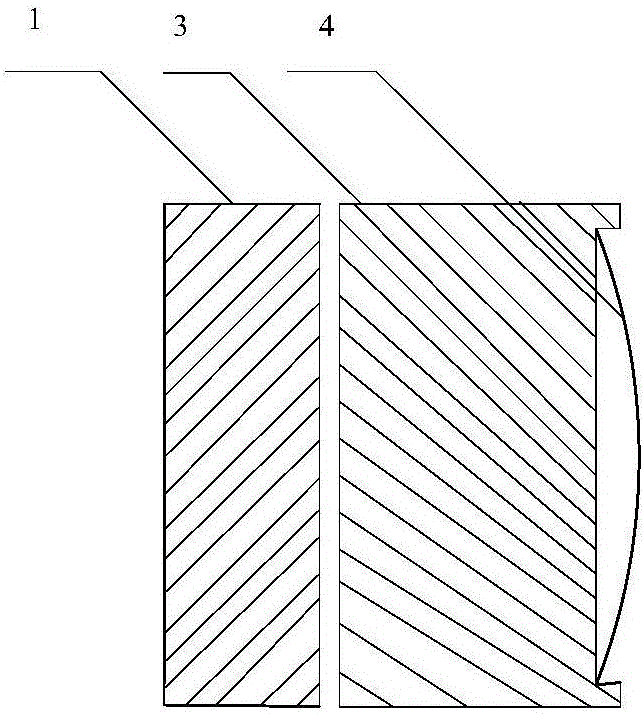

[0021] Such as figure 1 , 2 , 3, and 4, this embodiment discloses a sealing device for a micro-rotary engine, including a top sealing block 1 , a coupling spring 2 , a bottom sealing block 3 and a pretension spring 4 .

[0022] The top of the top sealing block 1 is arc-shaped, and the middle part of the arc is in contact with the cylinder wall during work. Bosses for fixing the connecting spring 2 are processed on both sides of the bottom, and bosses on both sides of the bottom are respectively processed for connecting with the bottom. The cantilever piece in contact with the sealing block 3 has a groove processed in the middle part of the bottom. Inside the top sealing block 1 is processed a ventilation hole for reducing the pressure difference of the gas. The upper port of the ventilation hole is opened on the outer side of the middle part of the arc in contact with the cylinder wall, and the upper ports are respectively opened at 1 / 2 of the semicircle on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com