Magnetic suspension water cooling unit and lithium bromide cold and heat pump unit double running system and method

A technology of water chiller and operation method, which is applied in the direction of machine operation, refrigerator, refrigeration and liquefaction, etc., and can solve the problem of low heating temperature of magnetic levitation water chiller, inability to provide cooling and hot water at the same time, and low energy efficiency ratio of rated load and other issues, to achieve the effect of large-scale adjustable cooling capacity and heating capacity, remarkable energy-saving effect, and saving electricity and water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

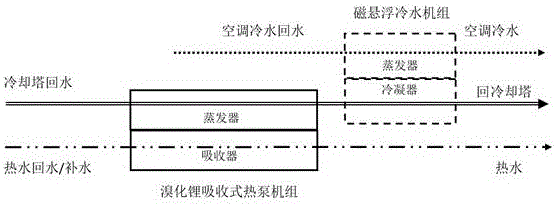

[0025] Such as figure 1 Shown: a dual-operation system of a magnetic levitation chiller and a lithium bromide cooling and heat pump unit, including a magnetic levitation chiller and a lithium bromide absorption heat pump unit, the lithium bromide absorption heat pump unit includes a first evaporator and an absorber, and the magnetic levitation chiller includes a second evaporator and the condenser; the heat exchange tube of the first evaporator enters the return water of the cooling tower, the water outlet of the heat exchange tube in the first evaporator is connected to the water inlet of the heat exchange tube in the condenser, and the outlet of the heat exchange tube in the condenser The cooling water output from the nozzle returns to the cooling tower again for recycling. The air outlet of the first evaporator is connected to the air inlet of the absorber; hot water is input into the heat exchange tube of the absorber for return or replenishment.

[0026] The water inlet ...

Embodiment 2

[0034] The difference from Example 1 is that the lithium bromide absorption heat pump unit is replaced by a lithium bromide absorption cold and warm water unit.

[0035] The specific principle is the same as that in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com