Method and device for improving precision of measuring ultra-thin film layer by ellipsometer

An ultra-thin film and ellipsometer technology, applied in the field of ellipsometer measurement, can solve problems such as large error in results and difficulty in achieving high precision requirements, and achieve the effects of reducing multiplicity, improving test accuracy, and simplifying the solution process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

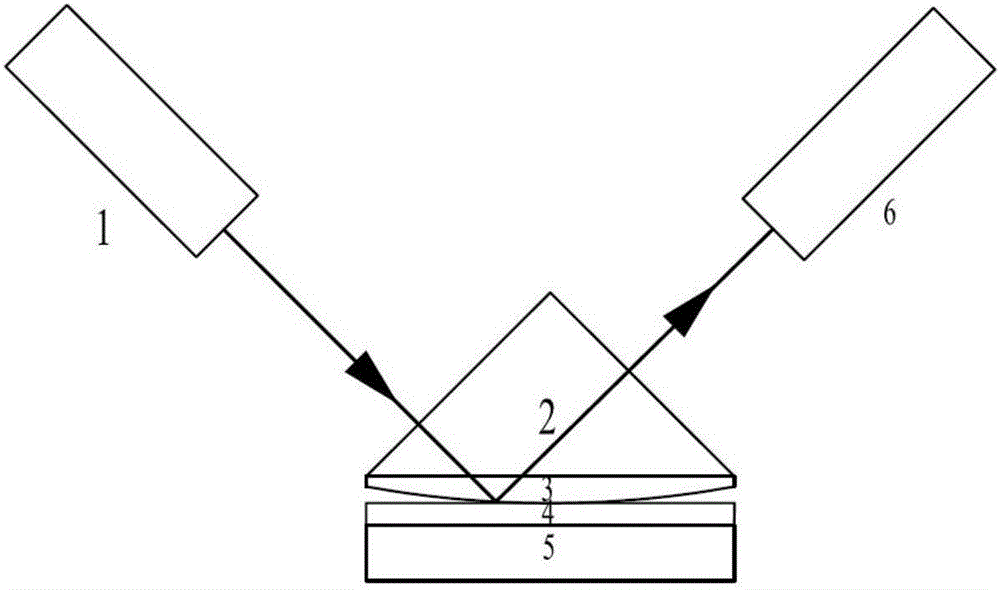

[0032] see first figure 1 , figure 1 It is a block diagram of the device for improving the precision of the ultra-thin film layer by the ellipsometer of the present invention. As can be seen from the figure, the device for improving the precision of the ultra-thin film layer by the ellipsometer of the present invention includes an ellipsometer incident arm 1, along which the output of the incident arm 1 The directions are a rectangular prism 2, a plano-convex spherical lens 3, an ultra-thin film layer 4, a glass substrate 5 and an ellipsometer exit arm 6 in sequence.

[0033] The Otto structure that excites the surface plasmon resonance is given by figure 1 The 2, 3, and 4 parts in the composition.

[0034] The optical path of the device is: the polarized light emitted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com