An automatic sampling device for tritium in water

A sampling device and water sample technology, applied in the sampling device and other directions, can solve the problems of undisclosed structure and parameter requirements of the tritium sampling device, inaccurate measurement results, and large human factors, and achieve sampling efficiency, strong collection ability, Avoid the effect of fog entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

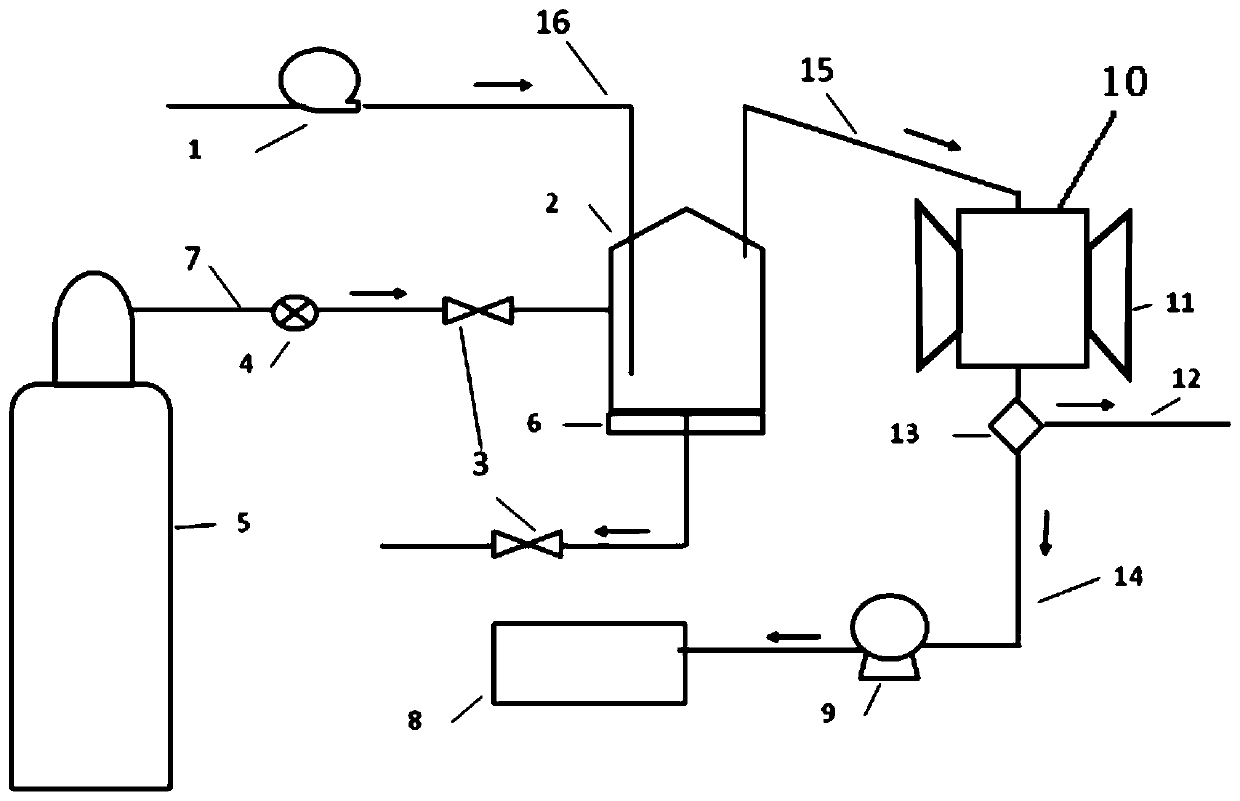

[0028] An automatic sampling device for tritium in water, the device includes a mechanical part and a control part; wherein the mechanical part includes an evaporation unit, a condensation unit and a collection unit; the control part includes a control box, a control panel, control software, a solenoid valve, a flow meter and a thermometer , All kinds of electrical switches are activated by relays, and one pole of the relay and solenoid valve is connected to the super five module of the control box, and the other pole is common. The automatic operation of the whole process of sampling, distillation and condensation can be realized through software. The control panel displays important information such as pressure, flow rate and temperature in real time. The whole process is completed automatically and is easy to use.

[0029] The evaporating unit includes an evaporating container 2 and a heating device 6 located at two sides below the evaporating container, the heating device...

Embodiment 2

[0040] The difference from Example 1 is that the heating device heats the temperature of the water sample in the evaporation container to 85° C.; the nitrogen inlet is located 3 cm above the liquid level to be sampled, and the nitrogen flow rate is 3 L / min.

Embodiment 3

[0042] The difference from Example 1 is that the heating device heats the temperature of the water sample in the evaporation vessel to 95° C.; the nitrogen flow rate is 10 L / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com