Test apparatus for research on laws of influence of sulfate reducing bacteria on stress corrosion cracking of metal

A metal stress and corrosion cracking technology, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, and the use of stable bending force to test the strength of materials, etc., can solve the influence law and mechanism of stress corrosion cracking of no metal bending specimens, etc. problem, to achieve the effect of high degree of automation, high loading accuracy and guaranteed continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

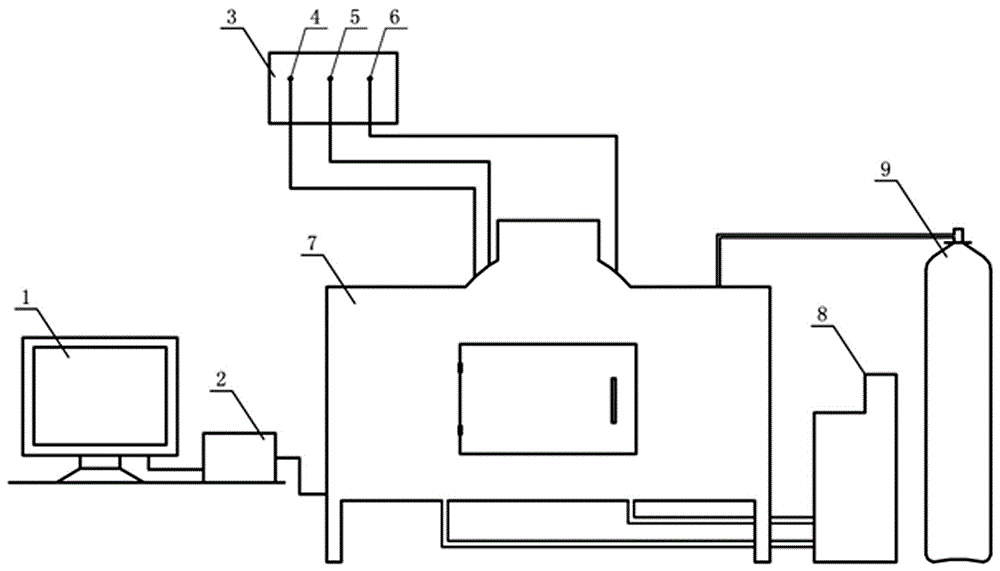

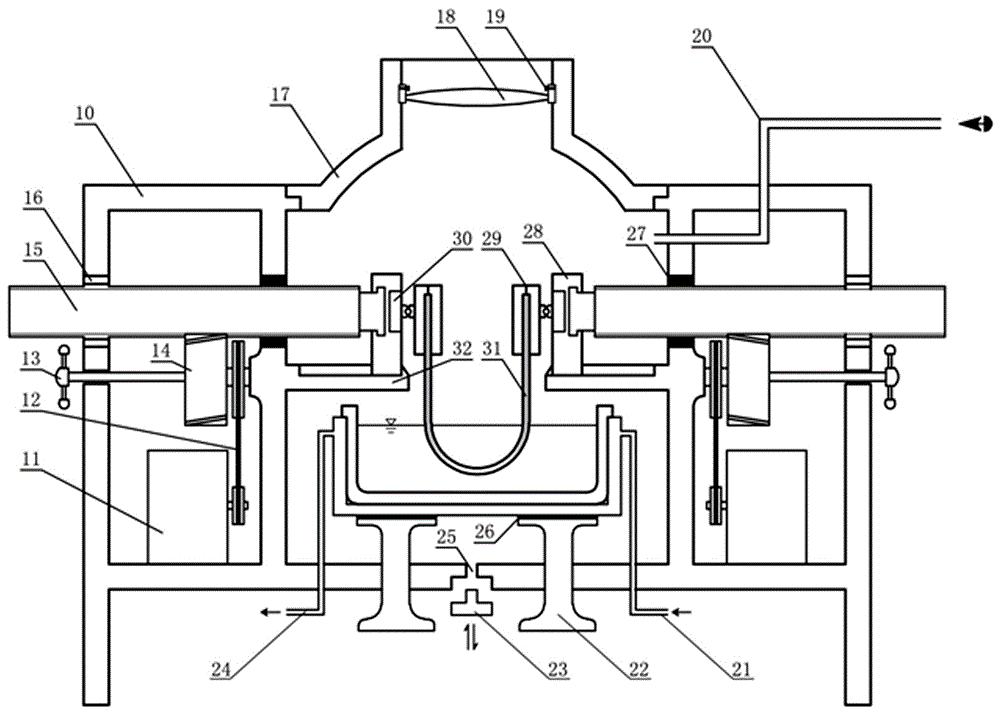

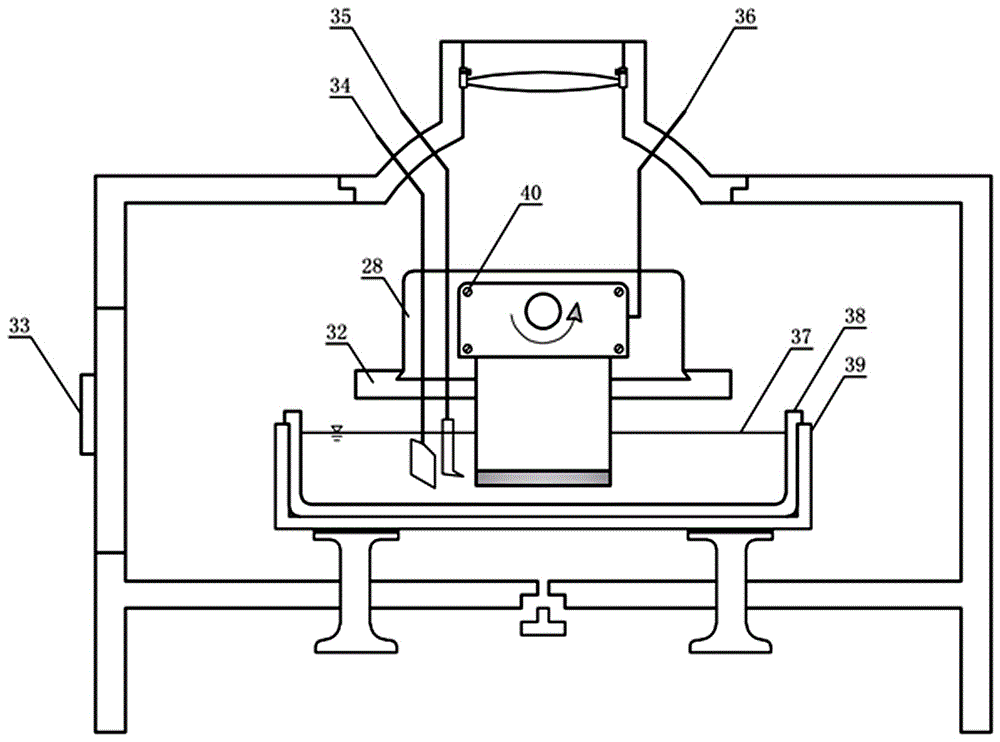

[0025] Such as Figure 1-3 As shown, the control system 2 is connected to the power system of the stress corrosion testing machine 7 through a circuit, and the computer 1 controls the speed, steering and rotation speed of the AC motor. The control system is composed of a programmable controller and a host computer. The auxiliary electrode interface 4, the reference electrode interface 5, and the working electrode interface 6 of the electrochemical workstation 3 are respectively connected with the three interfaces of the auxiliary electrode 34, the reference electrode 35, and the working electrode 36 provided by the stress corrosion testing machine 7 for testing Changes in electrochemical parameters during corrosion. The constant temperature water bath 8 is respectively connected with the constant temperature water inlet pipeline 21 and the constant temperature water outlet pipeline 24 provided by the stress corrosion testing machine 7. Before and during the test, the water hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com