Acoustic emission energy calculation method based on complete stress-strain curve of loaded coal and rock

A technology of full stress-strain and energy calculation, which is applied in the direction of material analysis, measuring devices, and processing detection response signals using acoustic emission technology, which can solve problems such as inability to use, falling off of the acoustic emission probe, and difficulty in installing the acoustic emission probe. To achieve the effect of clear physical meaning and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

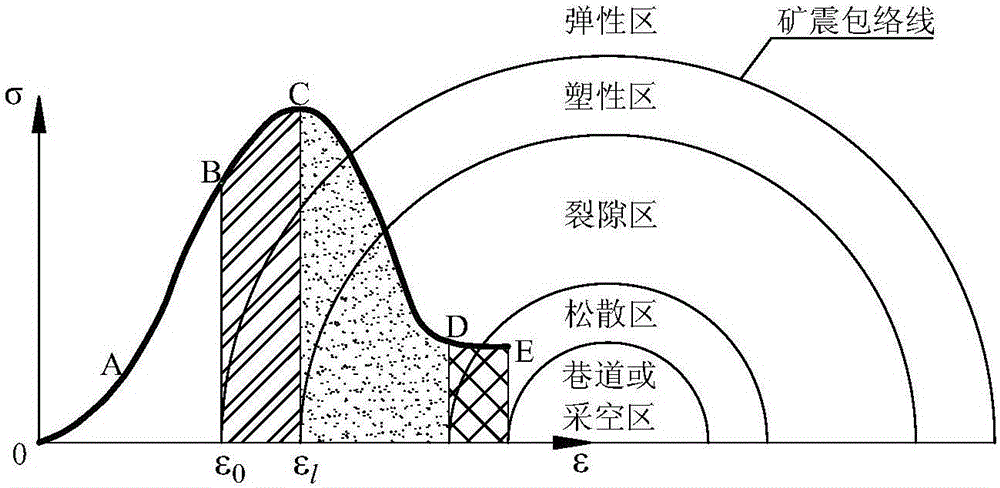

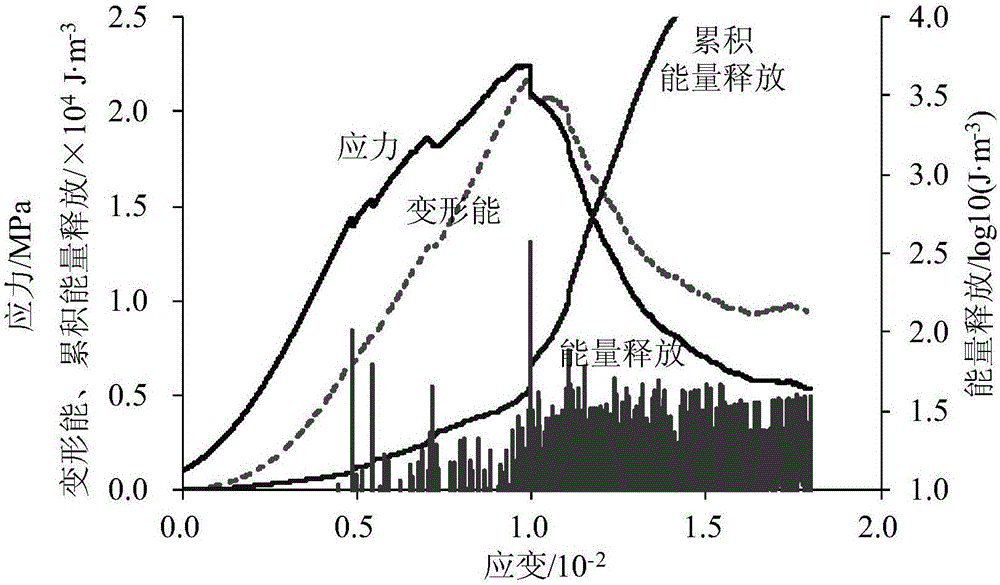

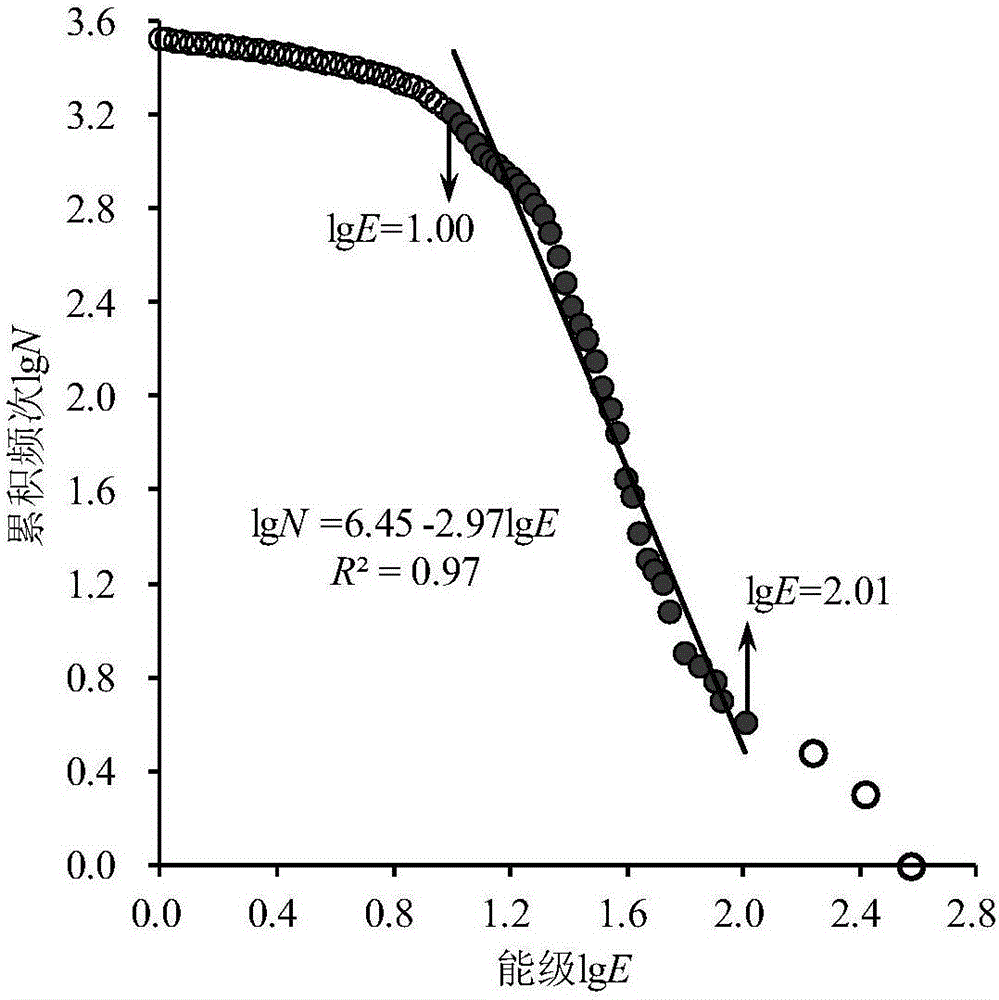

[0025] The acoustic emission energy calculation method based on the full stress-strain curve of the loaded coal rock mass is characterized in that it includes the following steps:

[0026] Step (1), calculate the deformation energy U according to the full stress-strain curve of the loaded coal and rock mass ε ;

[0027] Step (2), ergodic deformation energy U ε Curve, every certain time T compares U before and after ε Value, T is the test sampling interval;

[0028] Step (3), when comparing U ε When the value drops, it is recorded as an AE event and the AE information is recorded.

[0029] The aforementioned deformation energy U ε The calculation formula of is shown in formula (1-1):

[0030]

[0031] Among them, ε 1 , ε 2 , ε 3 is the strain in each direction of true triaxial, σ 1 , σ 2 , σ 3 is the stress in each direction of true triaxial.

[0032] The aforementioned acoustic emission energy calculation method based on the full stress-strain curve of the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com