A method for fault detection of motor stator winding

A motor stator and stator winding technology, applied in electrical winding testing, radiation pyrometry, electrical measurement, etc., can solve the problems of difficult follow-up repair, large winding damage, low detection accuracy, etc., achieve intuitive and accurate non-destructive positioning, reduce Hidden dangers, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

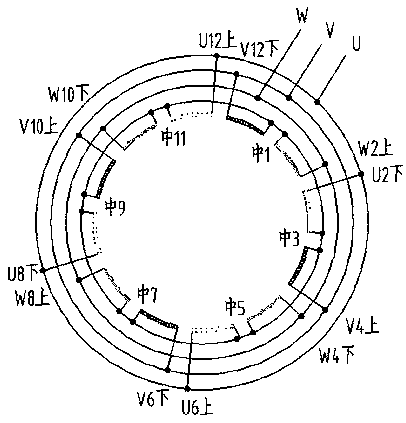

[0020] A motor stator winding fault detection method, energizing the motor stator winding (the current is about 4 times that of no-load), according to the abnormal temperature of the coil or coil group where the faulty lead wire is located compared with the rest of the coils (usually higher, after the lead wire is completely broken) Because there is no current passing, the temperature is low), use the temperature field observation screen of the infrared thermal imager to observe and record the temperature distribution characteristics of the entire winding intuitively and quickly, and then analyze and judge the fault lead.

[0021] The infrared thermal imager uses the infrared detector and the optical imaging objective lens to receive the infrared radiation energy distribution pattern of the measured target and reflect it on the photosensitive element of the infrared detector to obtain an infrared thermal image, which is consistent with the thermal image on the surface of the obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com