Watch jewel bearing bore arc processing device

A jewel bearing and processing device technology, which is applied to clocks, clocks, repair tools, etc., can solve the problems that the processing method is difficult to meet the needs and the processing accuracy requirements are very high, so as to avoid the difficulty of clamping, reduce the processing cost, and improve the process. The effect of material speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

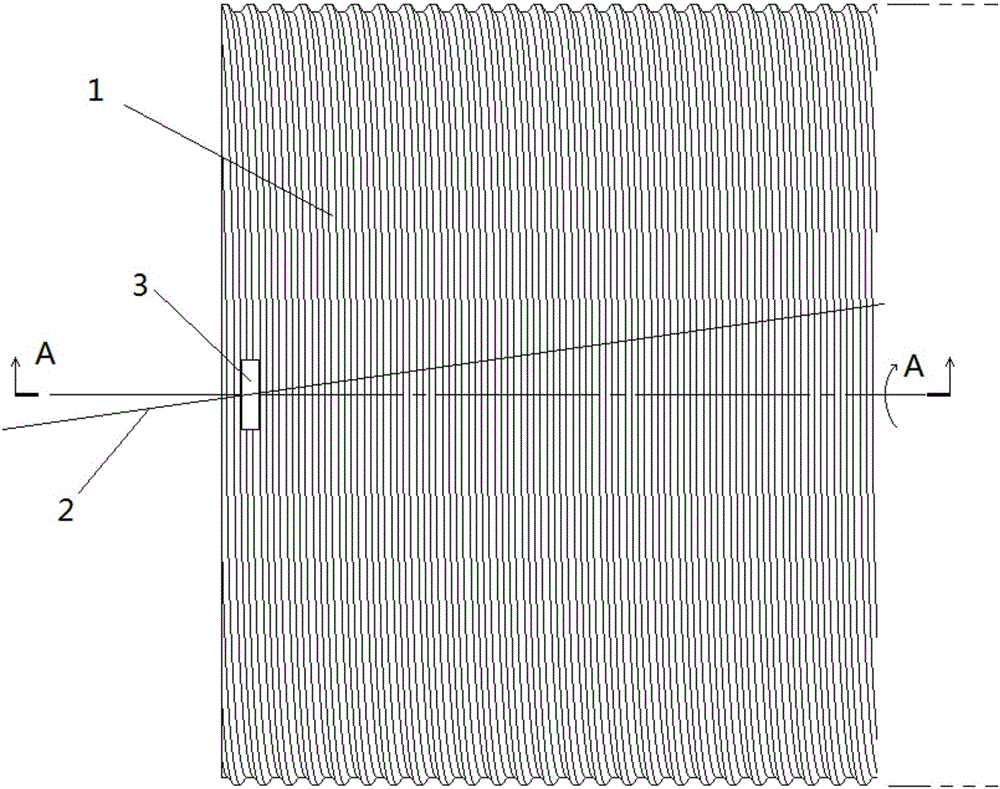

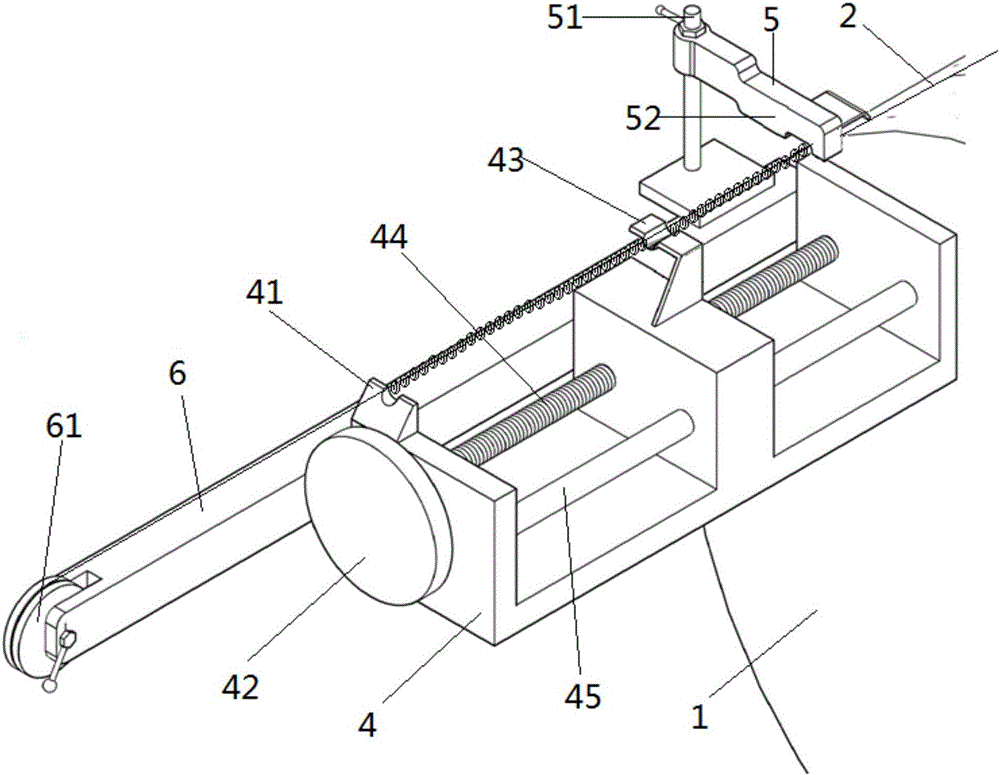

[0041] Such as figure 1 and figure 2 As shown in Fig. 1, a device for processing arc-shaped inner holes of watch jewel bearings, including a guide wheel mechanism and a feeding mechanism.

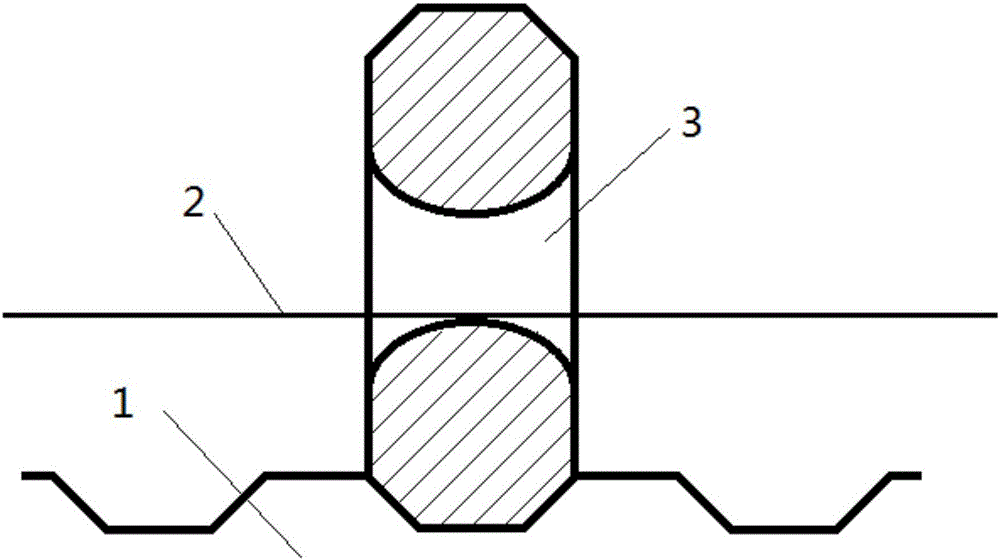

[0042] Wherein, the guide wheel mechanism includes a guide wheel 1 and a grinding steel wire 2 .

[0043] The guide wheel 1 is cylindrical, and the side of the guide wheel 1 is provided with a guide wheel spiral groove; the guide wheel spiral groove takes the axis of the guide wheel 1 as the axis and spirally surrounds the side of the guide wheel 1, and the cross section of the guide wheel spiral groove is consistent with the jewel bearing to be processed. 3 to match the shape.

[0044] One side of the gemstone bearing 3 to be processed is stuck in the spiral groove of the guide wheel, and a grinding steel wire 2 is passed through the inner hole of the gemstone bearing 3 to be processed; the grinding steel wire 2 presses the gemstone bearing 3 to be processed into the spiral groove of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com