Methods of using a phenolic fatty acid compound on a synthetic fibrous material

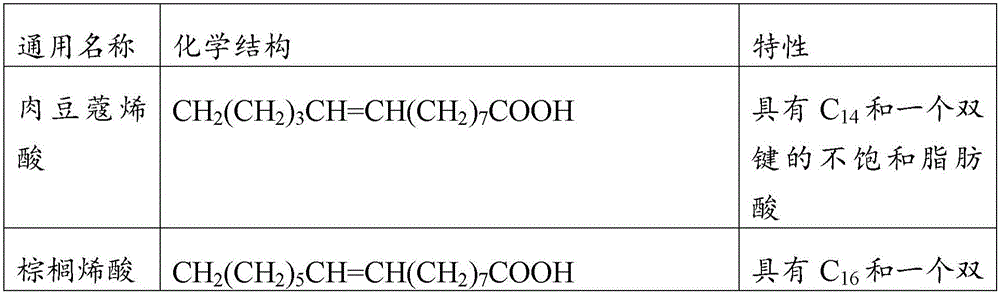

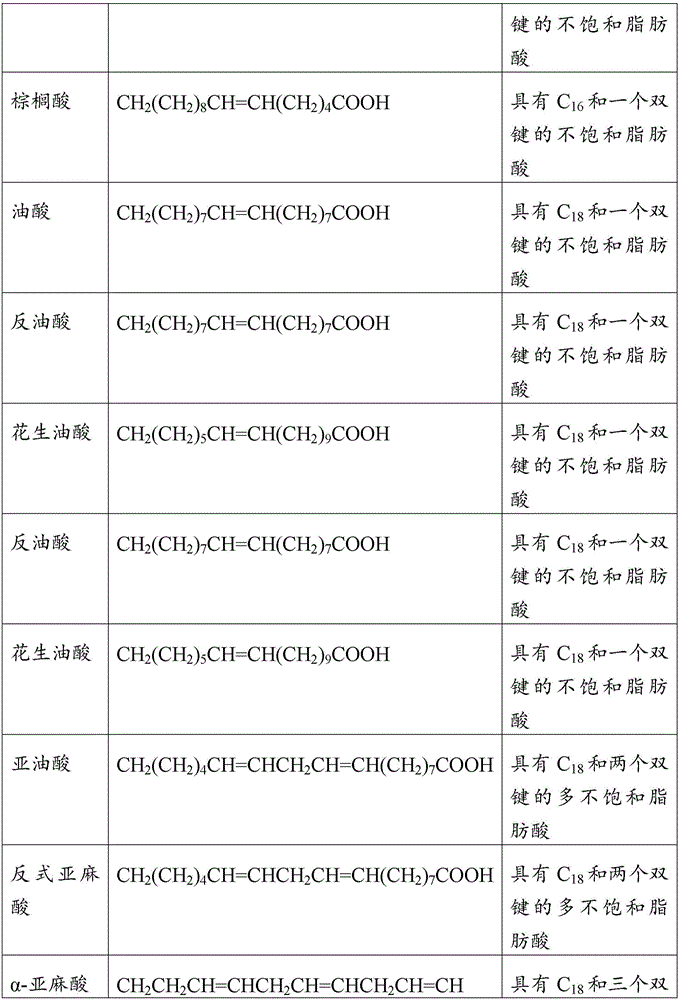

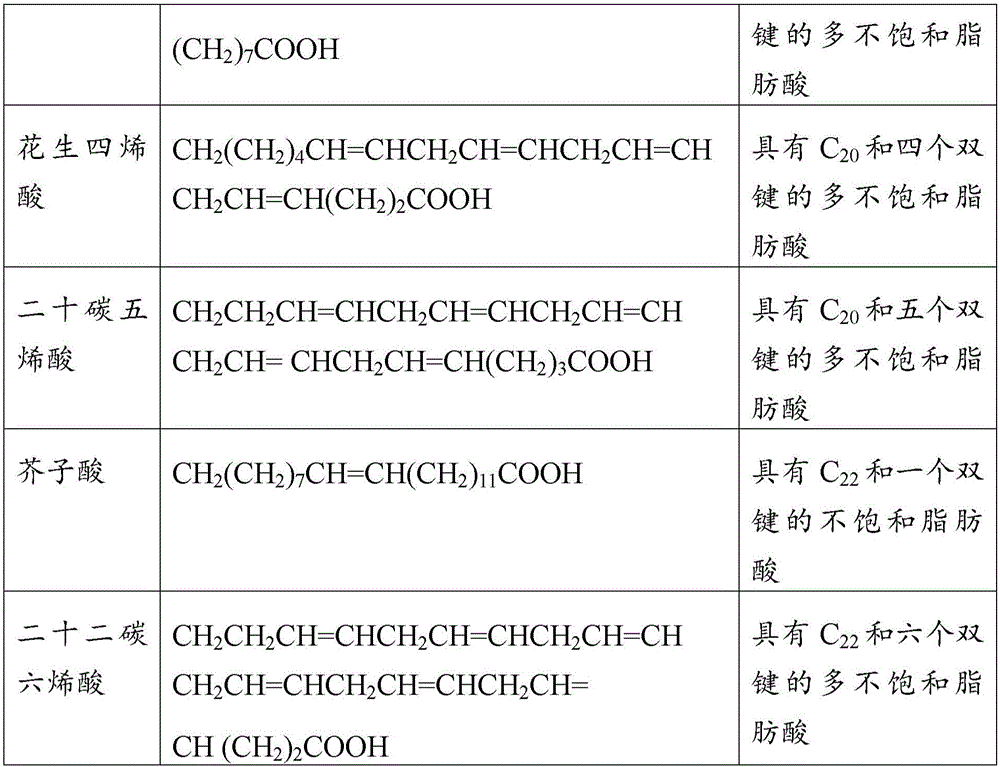

A technology for synthesizing fabrics and fatty acids, used in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] Embodiment 1: the preparation of phenol stearic acid

[0129] 100 parts of phenol and 5 parts of p-toluenesulfonic acid (PTSA) were heated in a glass flask equipped with a stirrer, thermometer and a water-cooled condenser arranged to return condensed water to the flask. The reaction mixture was heated to between 90°C and 105°C. Over a period of 3 hours, 100 parts of oleic acid were added to the reaction mixture while maintaining a reaction temperature of 90-105°C. The reaction was allowed to proceed for 5 hours with hourly checks for unreacted phenol by GC. At the end of the 5 hours, 45 parts of a 50% caustic solution were slowly added to the reaction mixture to neutralize the PTSA. Unreacted phenol was removed by distillation at a temperature of 130° C. under 40 mm vacuum. Optionally, to further reduce residual phenol, 10 pph of distilled water was added to the reaction mixture and distilled at 130 °C and 40 mm vacuum. The resulting product recovered in an amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com