Torque transmission device for a hybrid vehicle

A hybrid vehicle and torque transmission technology, which is applied to the layout of multiple different prime movers of hybrid vehicles and general power plants, motor vehicles, etc., can solve problems that are difficult and will not meet the isolation requirements, and achieve saving effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

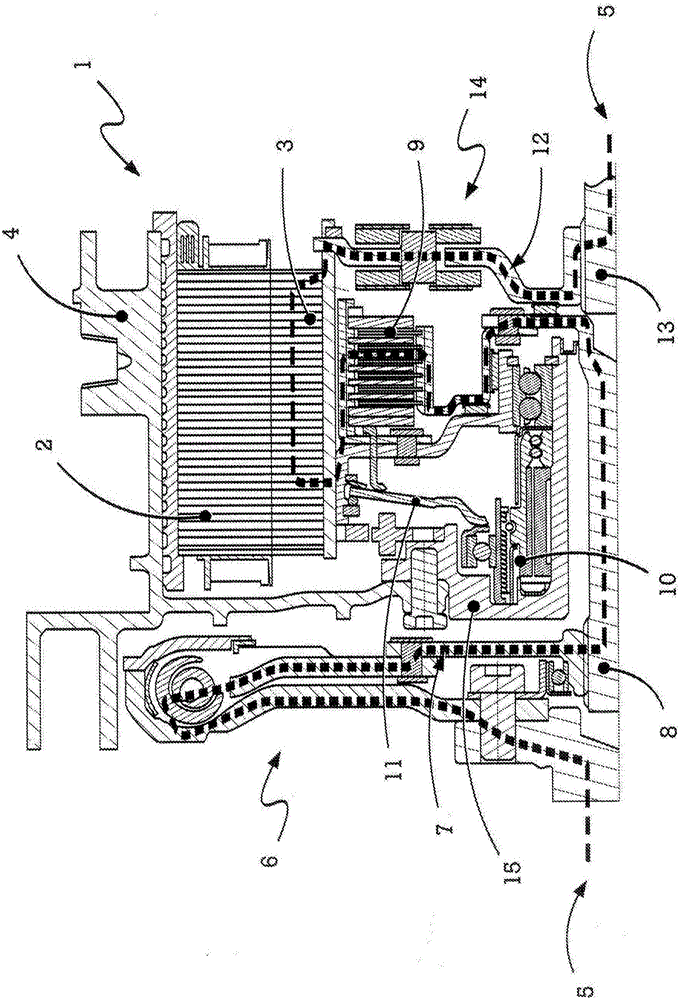

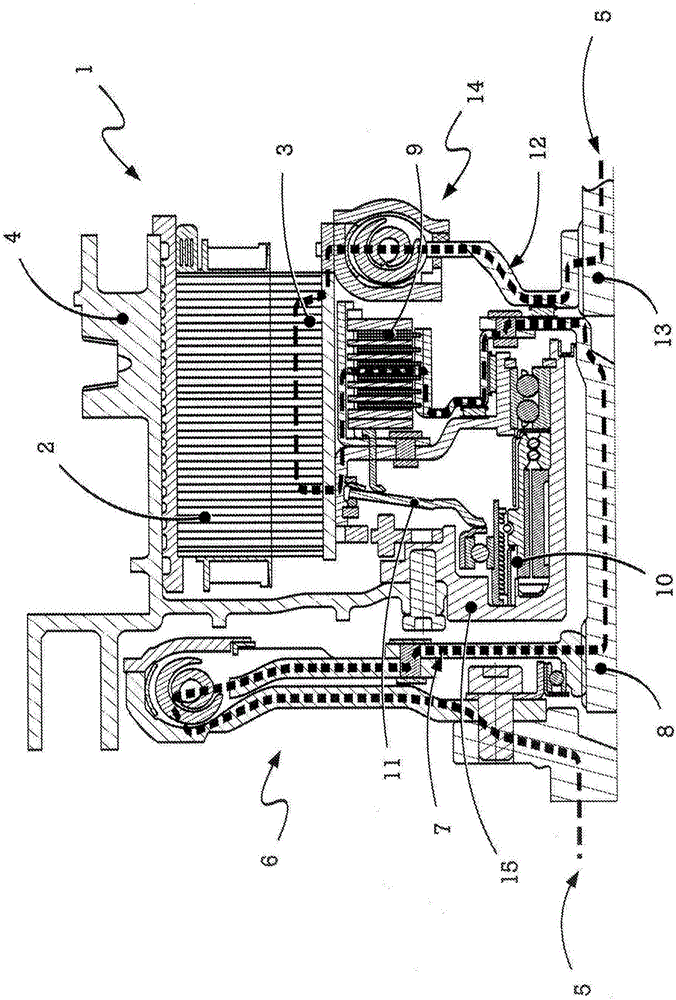

[0033] figure 1 A torque transmission device according to an embodiment of the invention is shown. First, we can see the stator 2 and rotor 3 of the motor 1 integrated in the torque transmission device. The stator 2 of the electric machine 1 is arranged in a stator housing 4, which currently simultaneously forms the housing 4 of the torque transmission device. In addition, the flow of force or moment can be seen, which is shown in the form of a dashed line 5 through the torque transmission device. The torque enters from the crankshaft via the arc spring damper 6 on the crankshaft side (on the left side of the drawing) and is introduced into the torque transmission device via the drive flange 7 and the drive shaft 8.

[0034] The torque from the drive shaft 8 arrives in a disconnect clutch 9 implemented here as a diaphragm clutch, which is operated via a disc spring 11 and a clutch actuator 10. Instead of a diaphragm clutch, for example, a single-plate dry clutch can also be arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com