Rolling wheel air distributing type gas pressure subsoiler

A rolling wheel and air distribution type technology, which is applied in the direction of soil lifting machinery, agricultural machinery and implements, plows, etc., can solve problems affecting air pressure subsoiling technology, difficult installation and adjustment, complex structure, etc., to achieve simplified structure and saving Energy and manufacturing cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

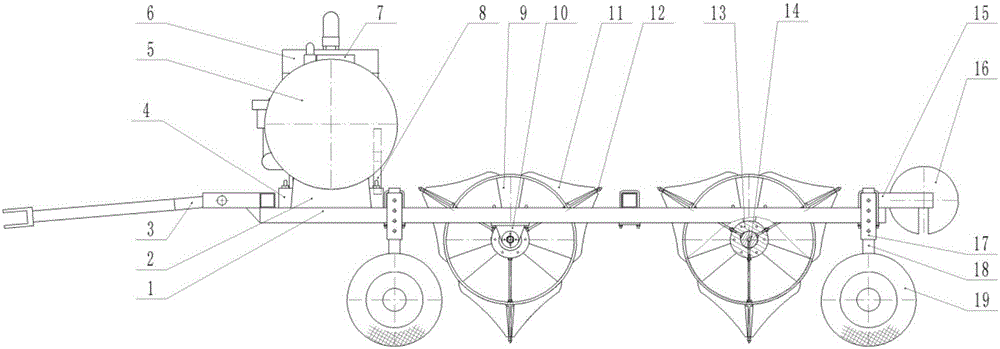

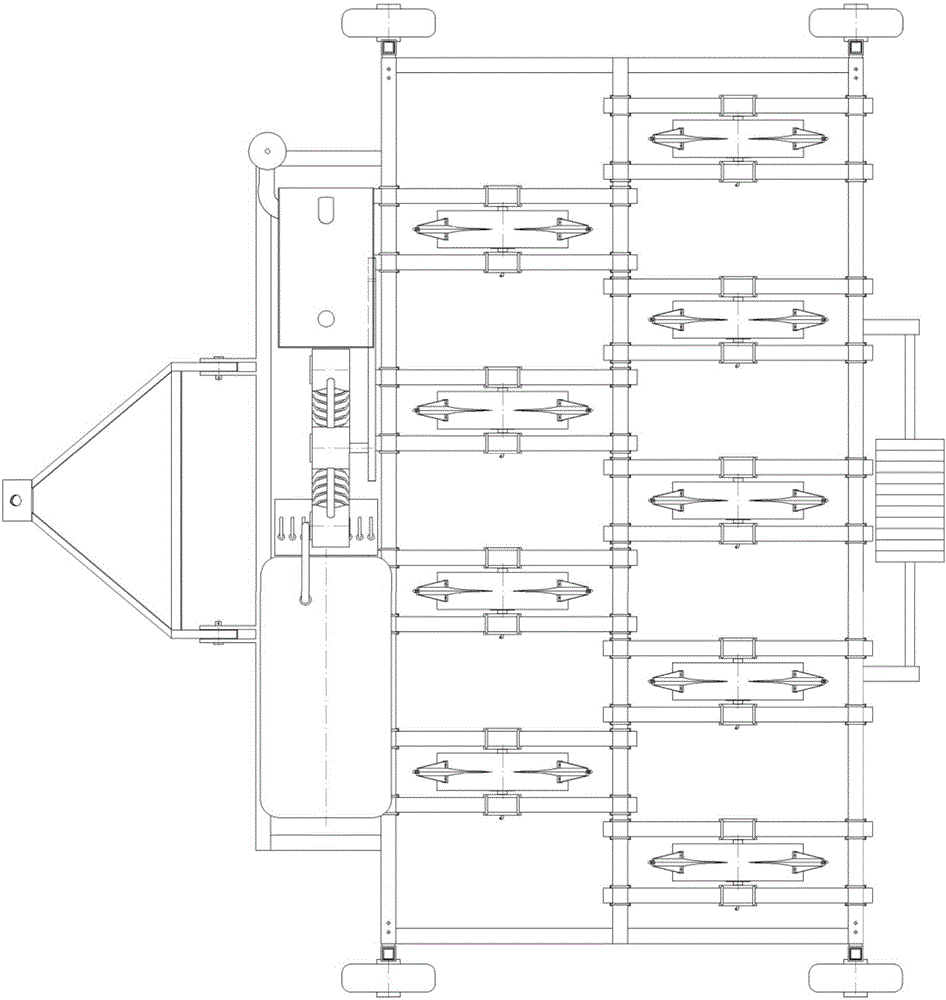

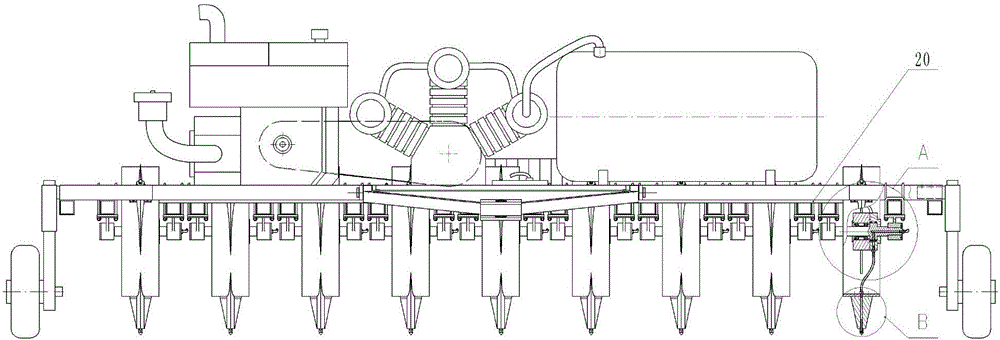

Embodiment 1

[0024]A rolling wheel gas distribution type pneumatic subsoiler, its main components include: frame 1, diesel engine 6, high pressure air pump 7, high pressure gas storage tank 5, air gun rolling wheel 9, gas transmission shaft 14, gas path conversion device 13, air gun press-in device 11, subsoiling air gun nozzle 12, gas transmission shaft support 10, rolling wheel support longitudinal beam 21, counterweight device, depth-limiting wheel support device, air pressure control system, etc., one of the The rolling wheel air distribution type pneumatic subsoiler is characterized in that the front end of the frame 1 is equipped with a traction frame 3, the rear end is welded with a counterweight bracket 15, and two depth-limiting wheel vertical adjustment sleeves 17 are respectively installed on both sides to fix the depth. Wheel bracket 18 and depth gauge wheel 19, a support plate 20 is fixed at the front, diesel engine 6 and high-pressure air pump 7 are fixed on the left side of s...

Embodiment 2

[0026] The air gun rolling wheel 9 is made of shaped steel and steel plate. The air gun rolling wheel 9 includes three parts: hub, web and rim. The hub is assembled on the gas transmission shaft 14 through a bearing, and the gas circuit converter 13 is fixed on the side of one end, so that There is no relative movement between the air circuit converter 13 and the air gun rolling wheel 9, and the axially fixed bearing end cover is installed on the side of the other end. Holes and positioning holes are spaced 120° apart from each other, and the webs are made of steel plates. The three webs are welded between the hub and the rim at 120° intervals, and are located on the central symmetry plane of the vertical axis of the air gun rolling wheel 9. During work, 3 groups of air gun press-in devices 11 are installed on the outer surface of the air gun rolling wheel 9 rims. During the rolling operation of the air gun rolling wheel 9, the air gun nozzle 12 for subsoiling is pressed into t...

Embodiment 3

[0028] The air gun press-in device 1 is welded and processed by triangular guard plates, seamless steel pipes and arc-shaped bases, and the seamless steel tubes are vertically welded on the symmetrical centers of 2 longitudinal triangular guard plates and 2 transverse triangular guard plates and aligned with the arc-shaped The base is vertical to form an air channel 28 of the air gun press-in device. The two ends of the air gun press-in device air channel 28 are processed with internal threads. It communicates with the converter air passage 27, the cross section of the longitudinal triangular guard plate is a gradually changing triangle, the cross section of the transverse triangular guard plate is a gradually changing rectangle, the arc base is provided with positioning holes and mounting holes, through the positioning holes and The mounting hole is fixed on the outside of the rim of the air gun rolling wheel 9, equipped with air gun pressing devices 11 of different sizes, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com