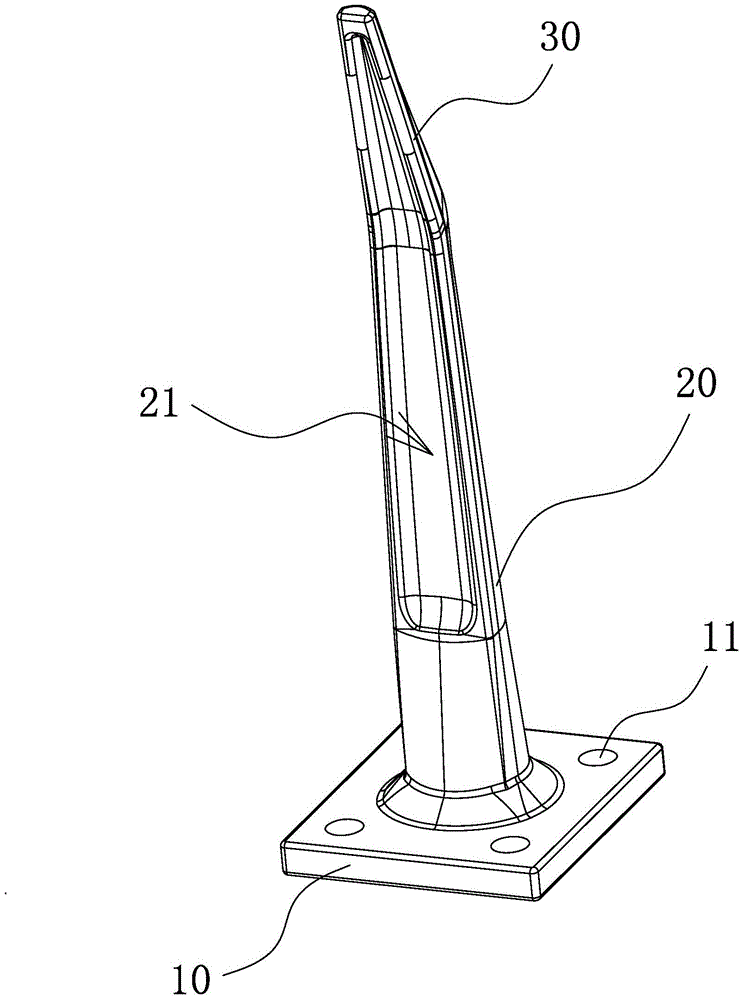

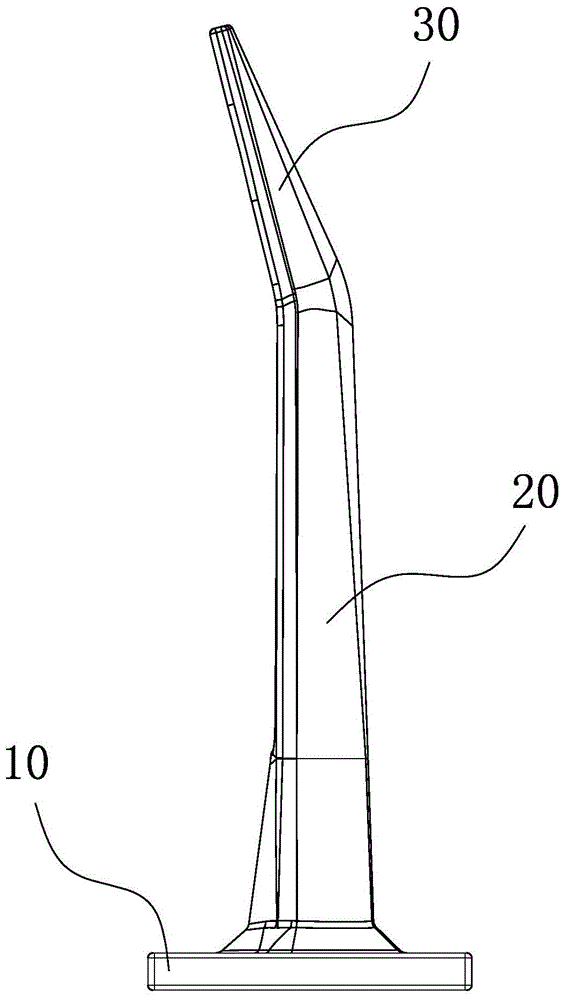

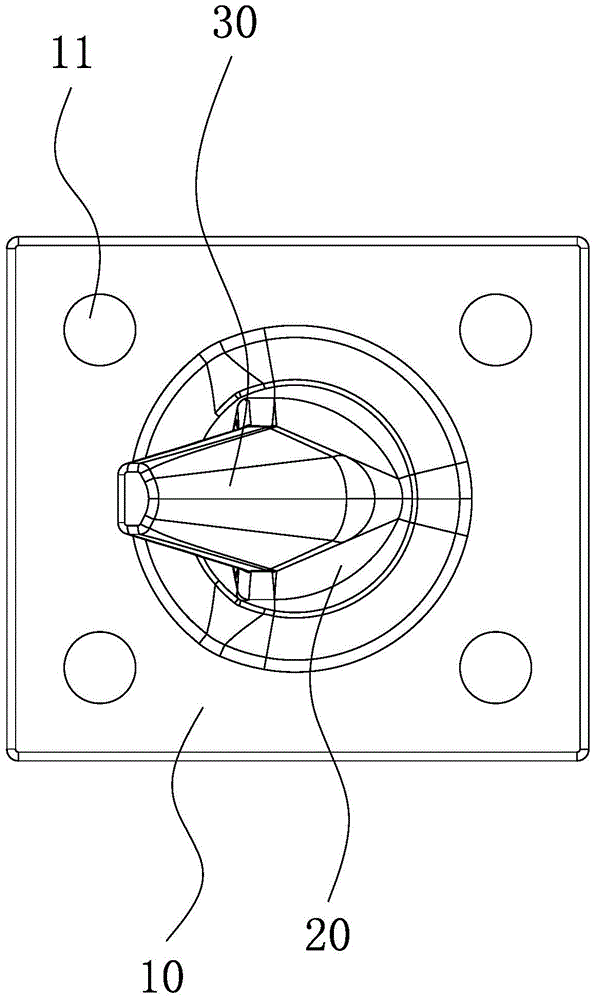

An improved plow point and its preparation method

A plow point and integrated technology, which is applied in the field of improved plow point for subsoiling and soil preparation, can solve the problems of low size accuracy, high resistance, and insufficient strength, and achieve the effects of good corrosion resistance, long service life and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of described plow point comprises the steps:

[0043] S1. Melting the alloy steel described in plow point at 1560-1600°C into molten steel;

[0044] S2. Pouring molten steel at 1560-1600°C into a mold baked at 850-900°C and kept warm for 0.5-1 hour. The pouring time is 8-12s. After the pouring is completed, the shell is shelled to obtain a plow point blank;

[0045] S3, cutting, grinding, polishing and cleaning the plow point blank to obtain a plow point semi-finished product;

[0046] S4. Carry out heat treatment to the plow point semi-finished product. During the heat treatment, the quenching temperature is 840-870°C, heat preservation for 1-3 hours, then tempering treatment at 380-400°C, heat preservation for 2-4 hours, and air cooling to room temperature to obtain Plow point end product.

Embodiment 1

[0048] The plow point alloy steel is smelted into molten steel at 1580°C; the plow point alloy steel is composed of the following chemical components in mass percentages: C: 0.42%; Mn: 1.00%; Si: 0.25%; Cr: 1.10%; Mo: 0.25%; S≤0.035%, P≤0.035%, the balance is Fe;

[0049] Molten steel was poured at 1580°C into a mold baked at 880°C and kept warm for 0.8 hours. The pouring time was 10s. After pouring, the shell was shelled to obtain a plow point blank;

[0050] Cutting, grinding, polishing and cleaning the plow point blank to get the plow point semi-finished product;

[0051] The plow point semi-finished product is subjected to heat treatment, the quenching temperature in the heat treatment is 850°C, heat preservation for 2 hours, then tempering treatment at 390°C, heat preservation for 3 hours, air cooling to room temperature, and the final plow point can be obtained.

Embodiment 2

[0053] The plow point alloy steel is smelted into molten steel at 1590°C; the plow point alloy steel is composed of the following chemical components in mass percentage: C: 0.43%; Mn: 0.90%; Si: 0.30%; Cr: 0.95%; Mo: 0.20%; S≤0.035%, P≤0.035%, the balance is Fe;

[0054] Molten steel was poured at 1570°C into a mold that was baked at 860°C and kept warm for 0.6 hours. The pouring time was 9s. After pouring, the plow point blank was shelled;

[0055] Cutting, grinding, polishing and cleaning the plow point blank to get the plow point semi-finished product;

[0056] The semi-finished plow point is subjected to heat treatment. During the heat treatment, the quenching temperature is 860°C, and the temperature is kept for 1 hour. Then, it is tempered at 385°C, kept for 4 hours, and air-cooled to room temperature. The final product of the plow point can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com