Upright lever-type self-locked clamping peanut plant pulling device

A technology of self-locking clips and levers, which is applied in excavating harvesters, agricultural machinery and implements, and applications, can solve problems such as low efficiency, labor-intensive, and inability to meet social needs, so as to improve work efficiency, reduce work intensity and damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

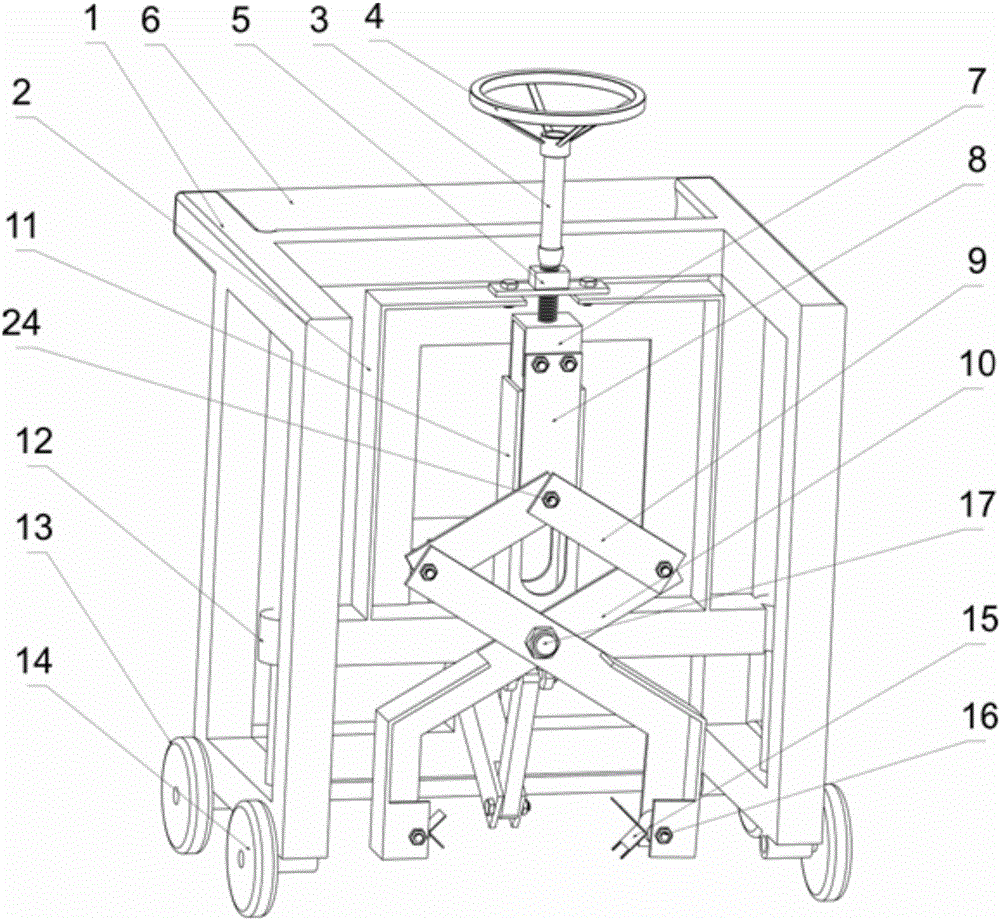

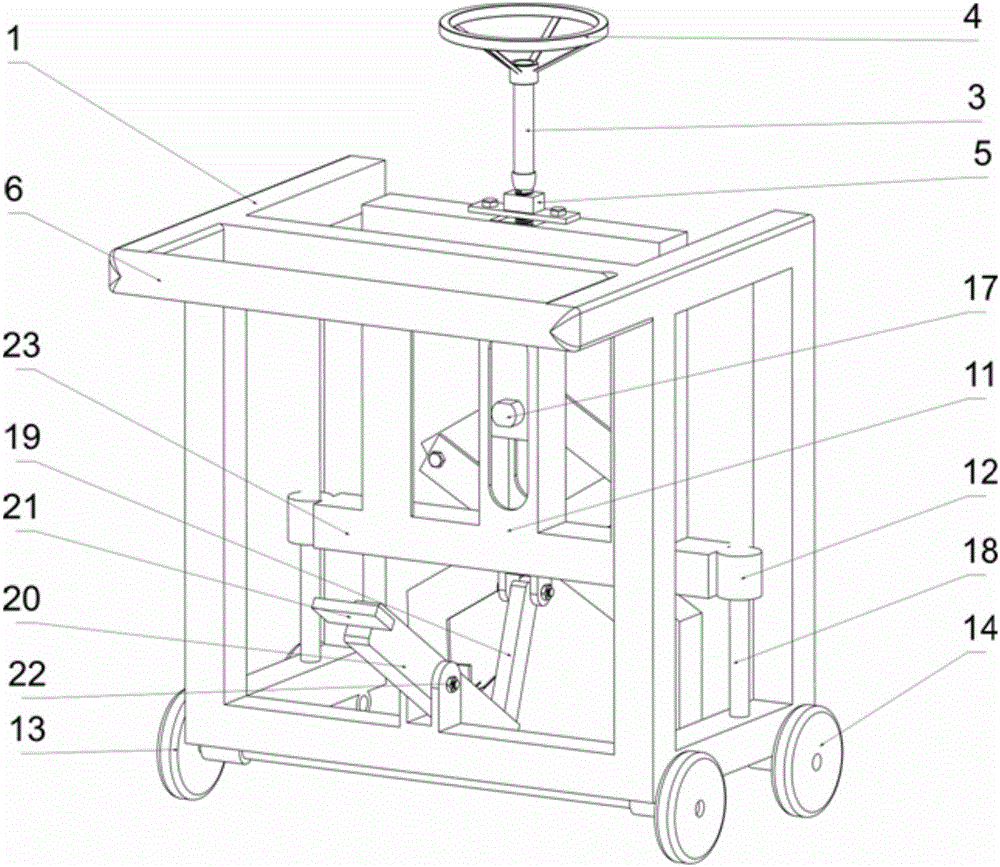

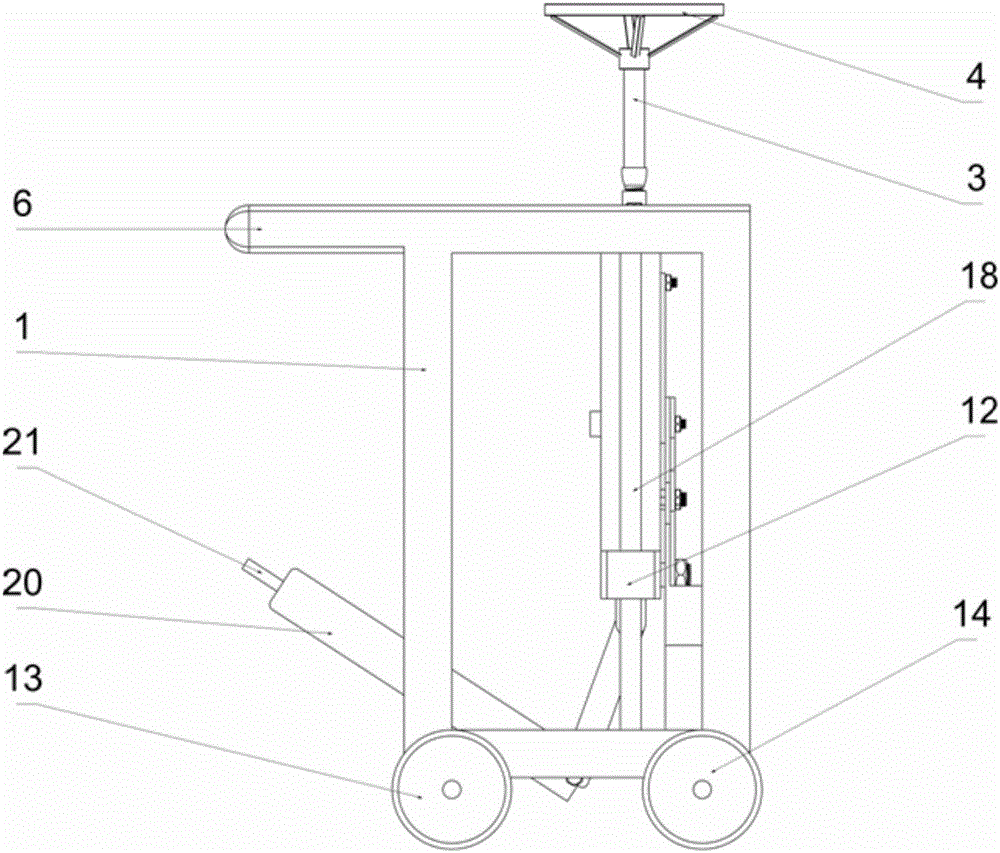

[0025] Such as Figure 1 to Figure 6 As shown, a kind of vertical lever self-locking clamping peanut pulling device according to the present invention includes a walking bracket, a lever lifting mechanism and a self-locking clamping mechanism. The specific structure and connection relationship are as follows:

[0026] Described walking support comprises vehicle frame 1, handle 6, rear wheel 13, front wheel 14 and column guide rail 18, and front wheel 14 is connected in the place ahead of vehicle frame 1 by front wheel shaft, and rear wheel 13 is connected on the front of vehicle frame 1 by rear wheel shaft. At the rear, two vertical cylindrical guide rails 18 are welded on the left and right sides of the vehicle frame 1, and the handle 6 is welded on the rear top of the vehicle frame 1. The vehicle frame 1 is welded by ten connecting rods to form a cuboid. The upper and lower surfaces of the frame 1 lack a connecting rod respectively.

[0027] Described lever elevating mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com