Water-saving irrigation system for intensive crop planting

A technology for irrigation systems and crops, applied in the field of water-saving irrigation systems, can solve problems such as ecological imbalance, environmental pollution, and energy depletion, and achieve better performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

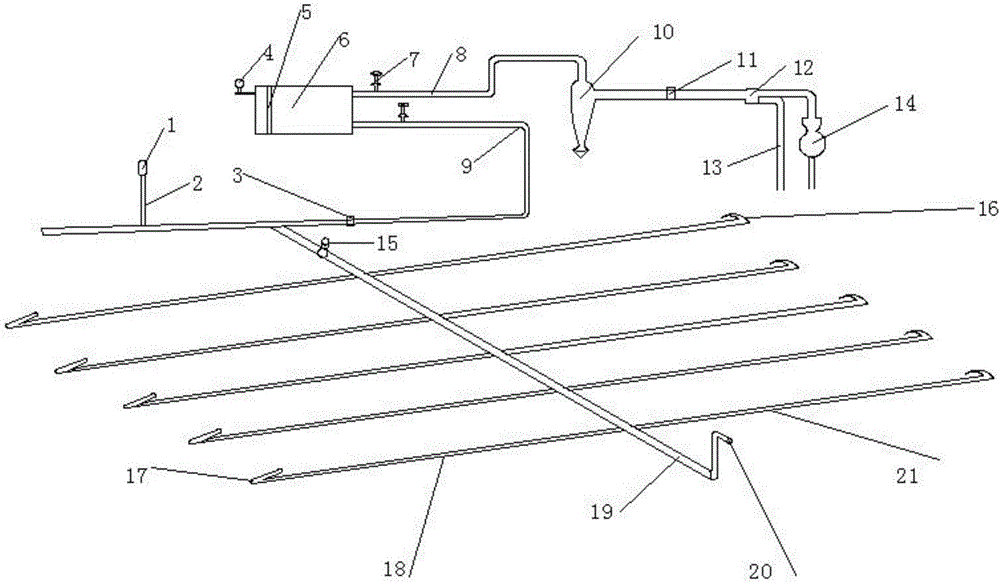

[0033] A water-saving irrigation system for intensive crop planting, used for water-saving irrigation for intensive crop planting, adopts drip irrigation mode for irrigation, uses sand filter system and water inlet system to filter the water drawn from the water source , filter out the sand contained in it, and then drip irrigation of crops through the drip irrigation system composed of branch pipes and capillary pipes. In the setting of capillary pipes, a certain range of spacing is used to effectively ensure that all crops can be drip-irrigated. Avoid the increase of engineering investment, and provide a strong guarantee for the user's cost control, such as figure 1 As shown, the following setting structure is adopted in particular: a sand filter system 6, a drip irrigation system supervisor 9, a drip irrigation system and a water inlet system are provided, the water inlet system is connected to the sand filter system 6, and the sand filter system 6 passes through the drip ir...

Embodiment 2

[0036] This embodiment is further optimized on the basis of the above embodiments. Further, in order to better realize the present invention, the capillary can be flushed according to needs, so as to avoid internal blockage due to deposits, thereby affecting the effect of drip irrigation, such as figure 1 As shown, the following arrangement structure is adopted in particular: the capillary 18 is a radix root, and a flushing valve 16 is arranged on one end of the capillary 18 near the main pipe 9 of the drip irrigation system, and the other end of the capillary 18 and the rest of the capillary 18 Plugs 17 are provided at both ends.

Embodiment 3

[0038] This embodiment is further optimized on the basis of any of the above-mentioned embodiments, further to better realize the present invention and facilitate the flow control of branch pipe water, such as figure 1 As shown, the following arrangement structure is adopted in particular: a ball valve 15 is arranged at the connection between the branch pipe 19 and the main pipe 9 of the drip irrigation system, and the ball valve 15 is arranged between the capillary 18 near the main pipe 9 of the drip irrigation system and the main pipe 9 of the drip irrigation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com