Ammonium salt organic amine early-strength non-alkaline accelerator and preparation method thereof

An organic amine and early-strength technology, which is applied in the field of ammonium salt organic amine early-strength non-alkaline accelerator and its preparation, and the field of wet-mix shotcrete for tunnel engineering, can solve the problem of unfavorable durability and early strength of concrete. Insufficient, skin corrosion damage and other problems, to achieve the effect of shortening the initial setting time, high early strength, shortening the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

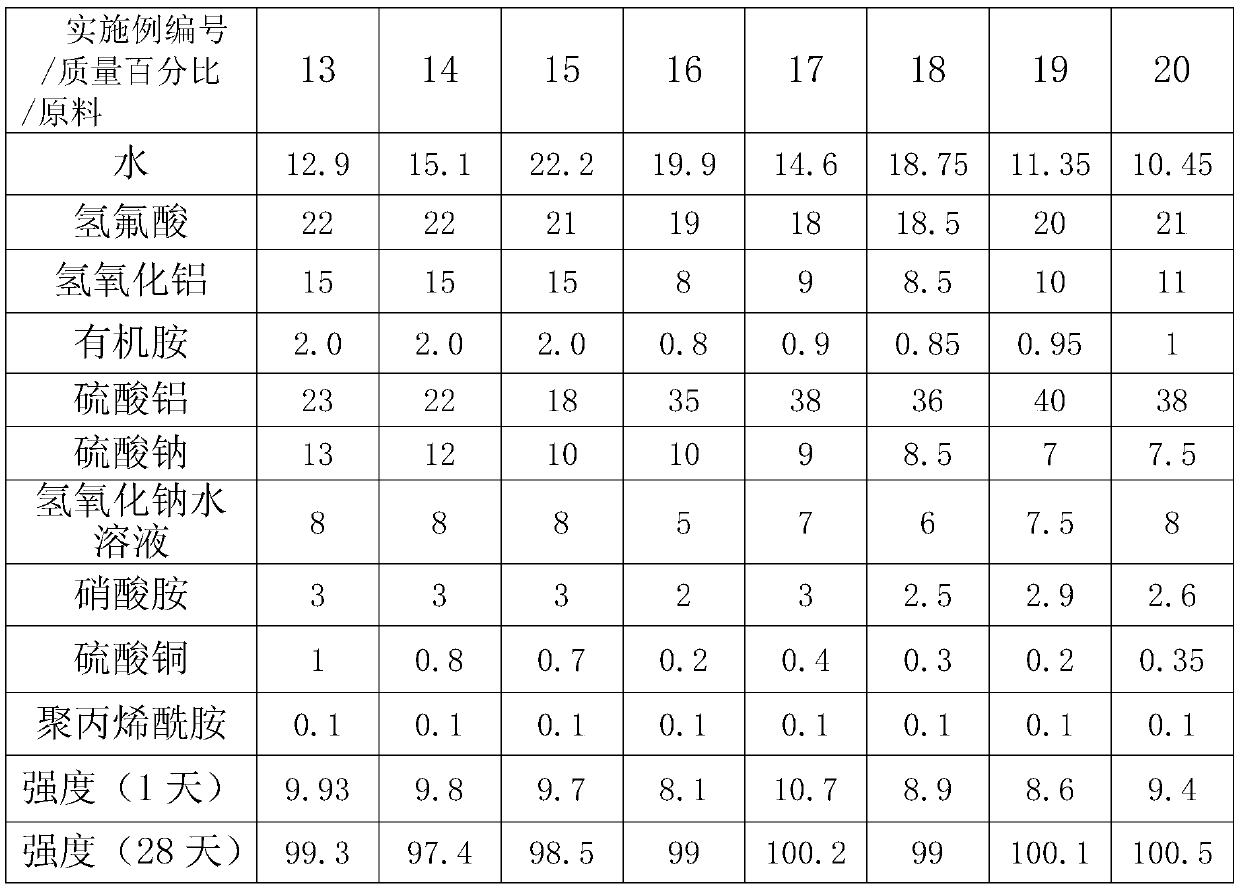

Examples

Embodiment 1

[0029] A kind of ammonium salt organic amine early-strength type non-alkaline quick-setting agent, is 20% hydrofluoric acid 10g, aluminum hydroxide 7g, triethanolamine 0.25g, two 0.25g of ethanolamine, 40g of aluminum sulfate, 18g of sodium sulfate, 3g of aqueous sodium hydroxide solution with a mass fraction of 30%, 1g of ammonium nitrate, 0.2g of copper sulfate, and 0.3g of polyacrylamide.

[0030] The specific method for preparing the ammonium salt organic amine early-strength non-alkaline accelerator is as follows: in a 500ml three-necked or four-necked flask equipped with stirring, heating and cooling devices, add 20g of water and 20% hydrofluoric acid in sequence Add 10g of acid, 7g of aluminum hydroxide, stir and observe the temperature rise. After 10 minutes, raise the temperature to 65-80°C. After stirring for 20 minutes, add 0.25g of triethanolamine and 0.25g of diethanolamine. After 10 minutes, add 40g of aluminum sulfate and stir. After 30 minutes, adjust the tempe...

Embodiment 2

[0033] An ammonium salt organic amine early-strength type non-alkaline quick-setting agent consists of 16.51g of water, 12g of hydrofluoric acid, 8g of aluminum hydroxide, 0.6g of triethanolamine, 38g of aluminum sulfate, 19g of sodium sulfate, It is prepared by mixing 4 g of sodium hydroxide aqueous solution with a mass fraction of 30%, 1.3 g of ammonium nitrate, 0.3 g of copper sulfate, and 0.29 g of polyacrylamide.

[0034] The specific method for preparing the ammonium salt organic amine early-strength non-alkaline quick-setting agent is: in a 500ml three-necked or four-necked flask equipped with stirring, heating and cooling devices, add 12g of hydrofluoric acid with a mass fraction of 20% successively, Stir and add 8g of aluminum hydroxide, raise the temperature to 65-80°C, add 0.6g of triethanolamine after stirring for 20 minutes, add 38g of aluminum sulfate after stirring for 10 minutes, stir for 30 minutes and adjust the temperature to 65-80°C, add 19g of sodium sulfat...

Embodiment 3

[0037] An ammonium salt organic amine early-strength type non-alkaline quick-setting agent consists of 19.86g of water, 14g of hydrofluoric acid, 9g of aluminum hydroxide, 0.7g of triethanolamine, 40g of aluminum sulfate, 10g of sodium sulfate, It is prepared by mixing 4.5 g of sodium hydroxide aqueous solution with a mass fraction of 30%, 1.4 g of ammonium nitrate, 0.3 g of copper sulfate, and 0.24 g of polyacrylamide.

[0038]Its preparation method is: in a 500ml three-necked or four-necked flask equipped with stirring, condensing and heating devices, add water and hydrofluoric acid in turn to the raw materials, then add aluminum hydroxide, stir for 20 minutes, add organic amine, and stir for 10 minutes Add sulfuric acid, after the aluminum sulfate is completely dissolved, add sodium sulfate, sodium hydroxide solution, ammonium nitrate, copper sulfate, and polyacrylamide in sequence. During stirring, control the temperature of the reactants at 50-90°C, stir for 30 minutes af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com