Ultrasonic triggering auxiliary device and method for self-repairing microcapsule of cement-based material

A technology of self-healing microcapsules and cement-based materials, applied in microcapsule preparations, measuring devices, analytical materials, etc., can solve the problem that the application of ultrasonic microcapsules has not been reported yet, and achieves easy promotion, good adjustability, and application prospects. expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

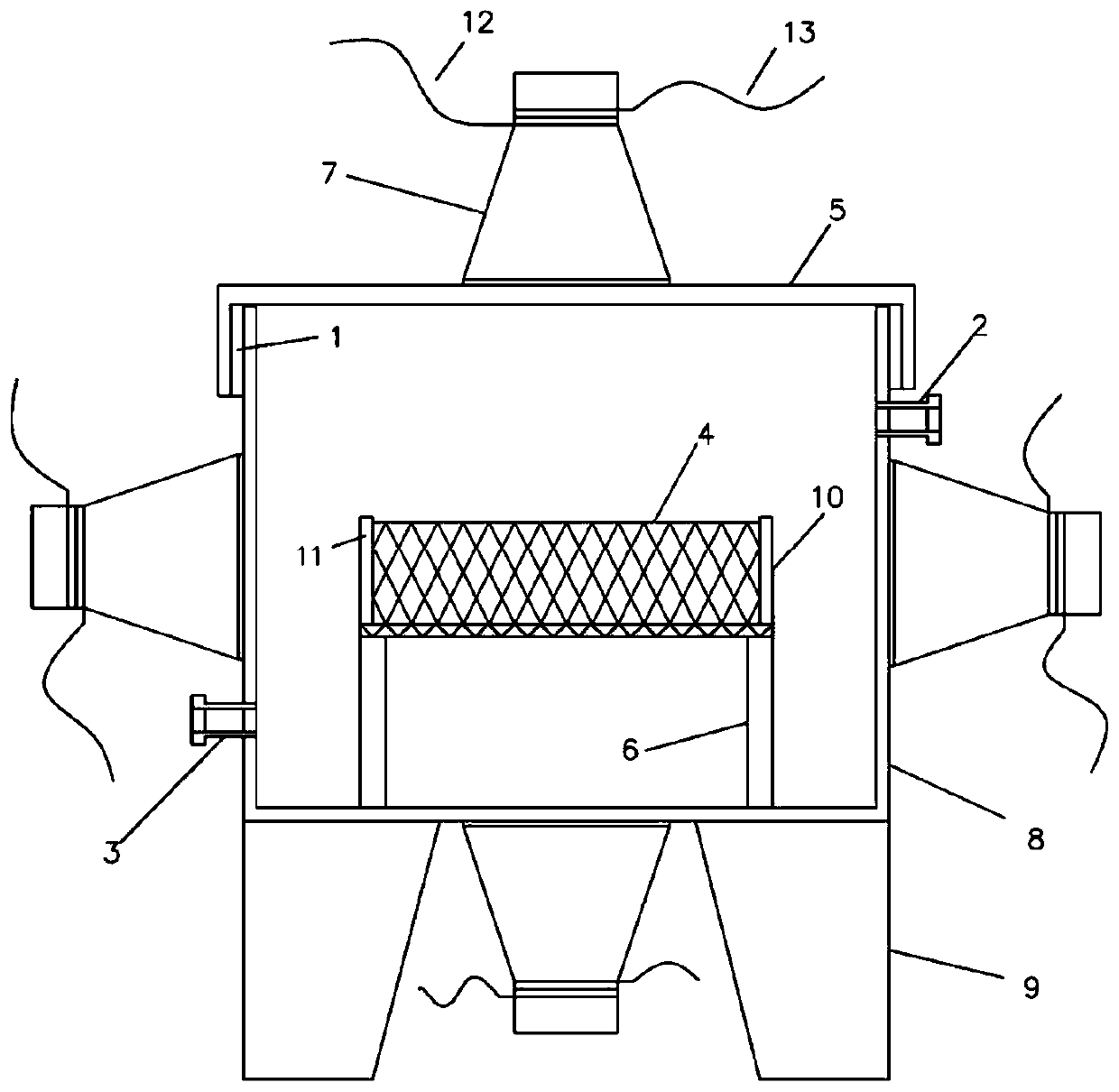

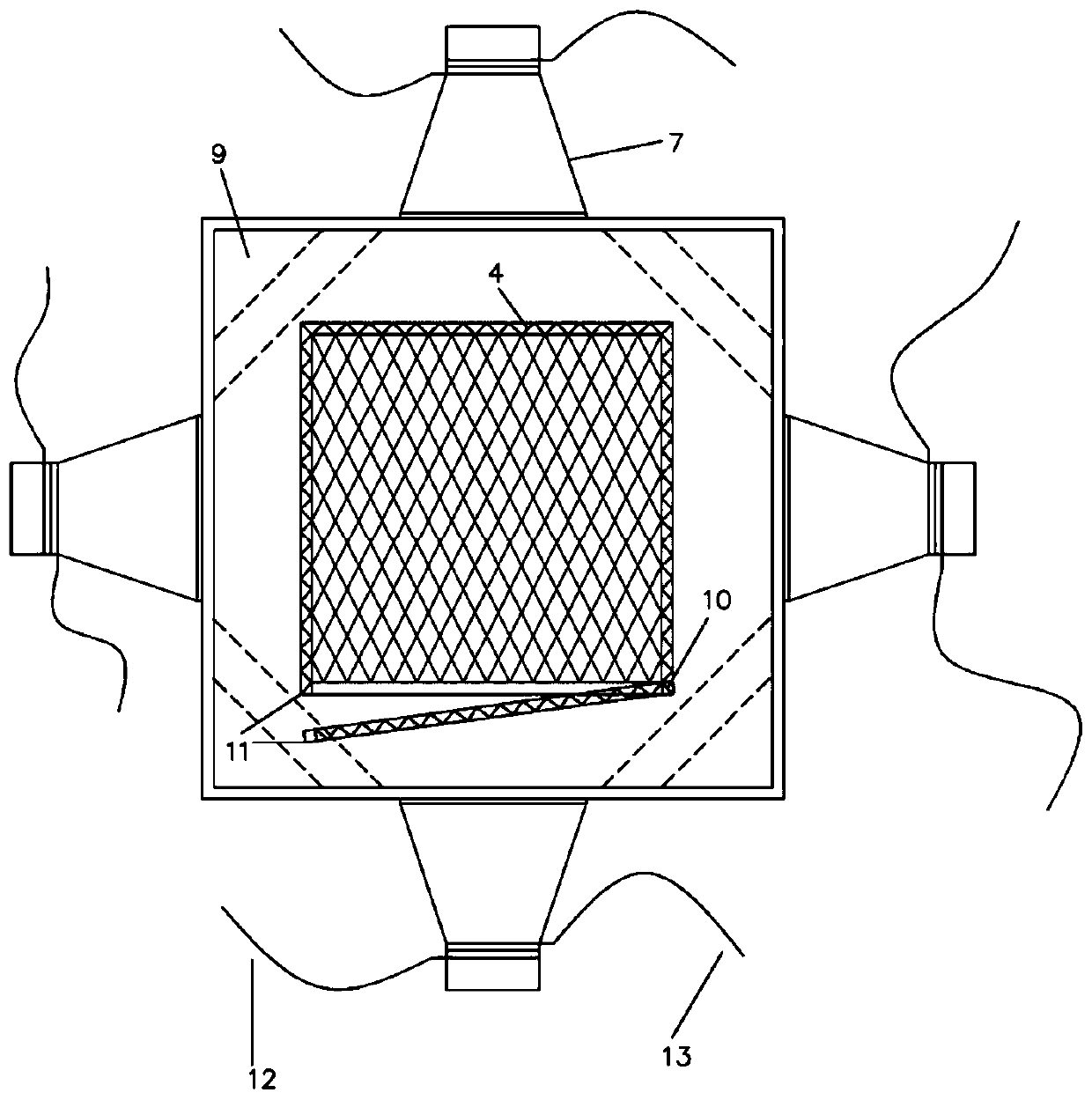

[0025] An ultrasonic trigger auxiliary device for cement-based material self-repairing microcapsules, such as figure 1 , figure 2 Shown, including container, ultrasonic device, test piece fixing device and circulating water device;

[0026] The container is a hollow cubic structure, with a container cover 5 on the top, a container support 9 as a support base at the bottom, and a water inlet 3 and a water outlet on the lower and upper parts of the two opposite sides of the container. 2.

[0027] The size of the container is 250mm×250mm×200mm. The container material is engineering plastic, plexiglass or nylon.

[0028] The length and width of the container cover 5 are slightly larger than 250 mm, and a rubber ring 1 is installed inside to facilitate clamping with the container, ensuring the container is airtight, and preventing the water in the container from overflowing.

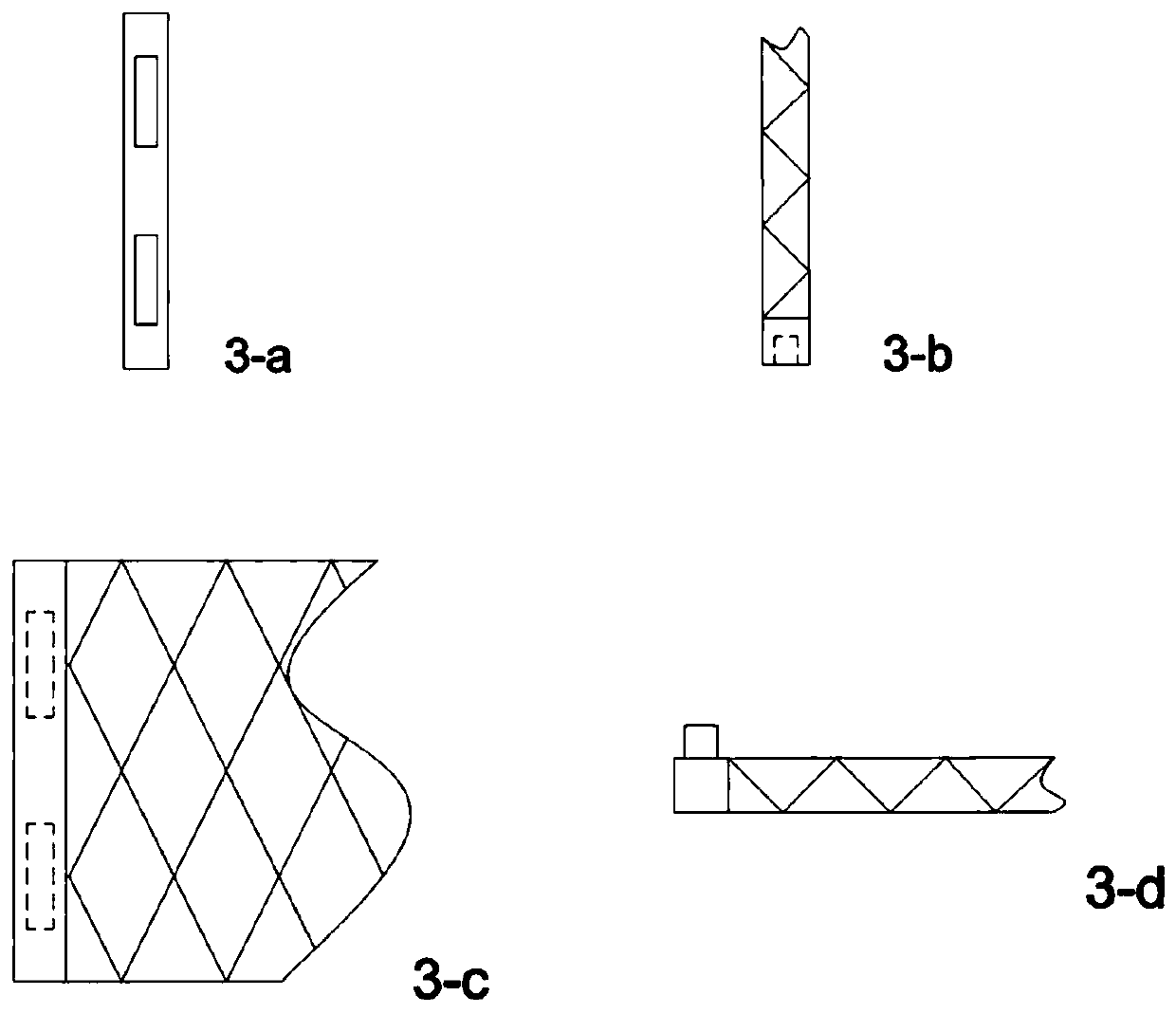

[0029] The ultrasonic device is an ultrasonic vibrator 7, which is 6 in number, glued together with the containe...

Embodiment 2

[0038] An ultrasonic trigger method for cement-based material self-healing microcapsules is specifically as follows:

[0039] Connect the hose connected to the cold water reservoir of the circulating water device to the water inlet 3, and connect the hose connected to the cold water reservoir to the water outlet 2. Turn on the circulating water device, and the water with constant water temperature from the lower water inlet 3 Enter, the water outlet from the high water outlet 2 is cooled back, and the container is filled with water by the pressure of the vacuum pump, and the water in and out takes away the excess heat in real time to ensure a constant temperature in the container; connect the positive pole of each ultrasonic vibrator in parallel with the positive pole, and the negative pole with The negative poles are connected in parallel, and then the positive outgoing line 12 is connected to the positive electrode of the ultrasonic generator, and the negative outgoing line 13 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Waist length | aaaaa | aaaaa |

| Waist length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com