Buoyance switch for track field drainage

A buoyancy switch and track technology, applied in the agricultural field, can solve the problems of accelerating drought and wasting water resources, and achieve the effect of fast drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

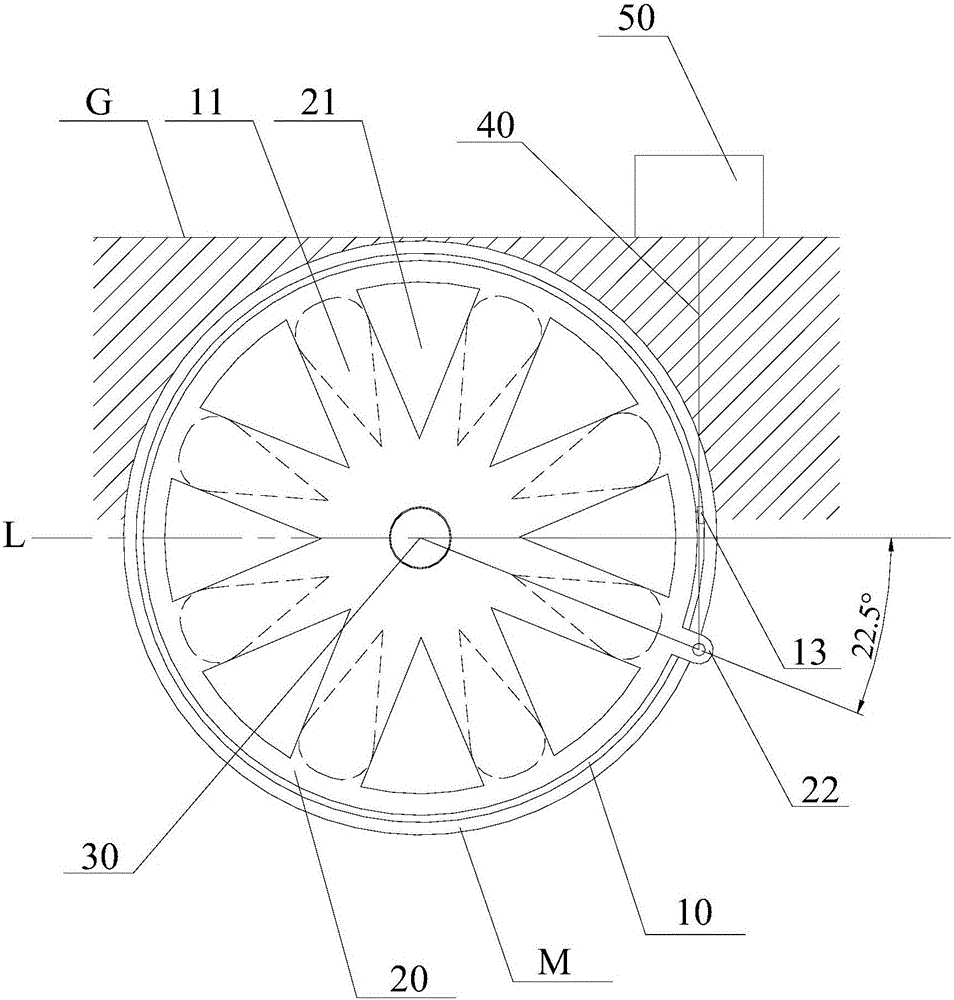

[0018] Buoyancy switch for drainage of track fields, such as figure 1 As shown, it includes an inner water retaining plate 10 and an outer water retaining plate 20. The inner water retaining plate 10 is fixed at the water outlet of the seepage and drainage waterlogging pipe M, and the outer periphery of the inner water retaining plate 10 is in interference fit with the inner wall of the seepage and drainage waterlogging water pipe M. Prevent water from flowing out between the inner water retaining plate 10 and the seepage and drainage waterlogging pipe M. The inner water retaining plate 10 is evenly distributed with eight inner water passing holes 11, and the eight inner water retaining holes 11 form a circular array; the outer water retaining plate 20 is connected with the inner water retaining plate 10 through a central axis 30, and the outer water retaining plate The plate 20 is close to the inner water retaining plate 10, and the outer water retaining plate 20 can rotate a...

Embodiment 2

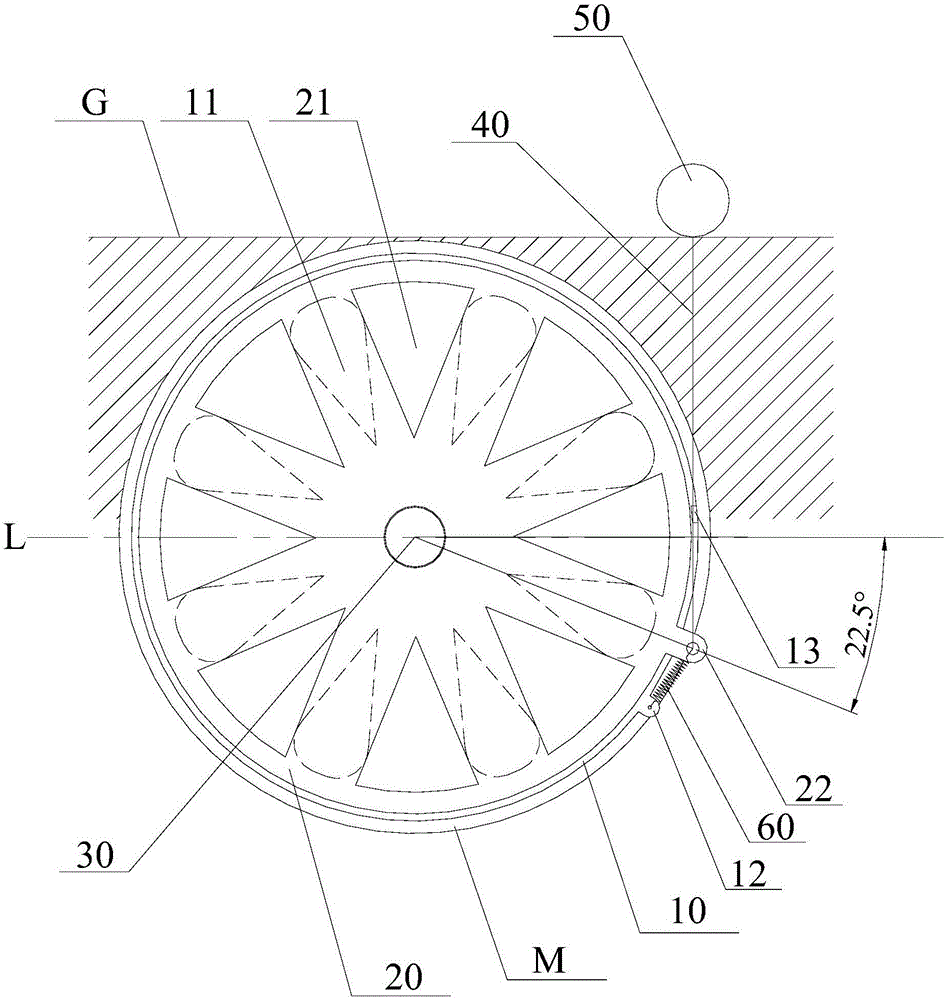

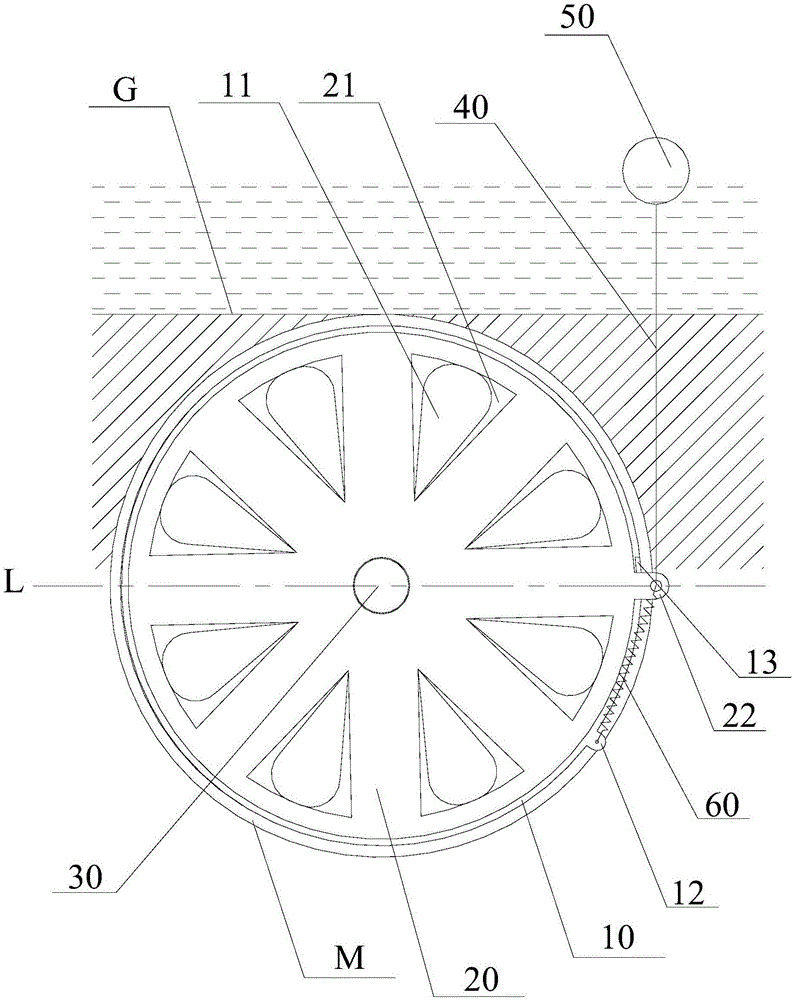

[0020] Buoyancy switch for drainage of track fields, such as figure 2 As shown, it includes an inner water retaining plate 10 and an outer water retaining plate 20. The inner water retaining plate 10 is fixed at the water outlet of the seepage and drainage waterlogging pipe M, and the outer periphery of the inner water retaining plate 10 is in interference fit with the inner wall of the seepage and drainage waterlogging water pipe M. Prevent water from flowing out between the inner water retaining plate 10 and the seepage and drainage waterlogging pipe M. The inner water retaining plate 10 is evenly distributed with eight inner water passing holes 11, and the eight inner water retaining holes 11 form a circular array; the outer water retaining plate 20 is connected with the inner water retaining plate 10 through a central axis 30, and the outer water retaining plate The plate 20 is close to the inner water retaining plate 10, and the outer water retaining plate 20 can rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com