A kind of cigarette holder and preparation method thereof

A mouth stick and cigarette technology, which is applied to tobacco, e-liquid filter, cigarette manufacturing and other directions, can solve the problems of soft hand feel and insufficient toughness of mouth stick, and achieve the effects of cheap and easy-to-obtain raw materials and simple and controllable preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

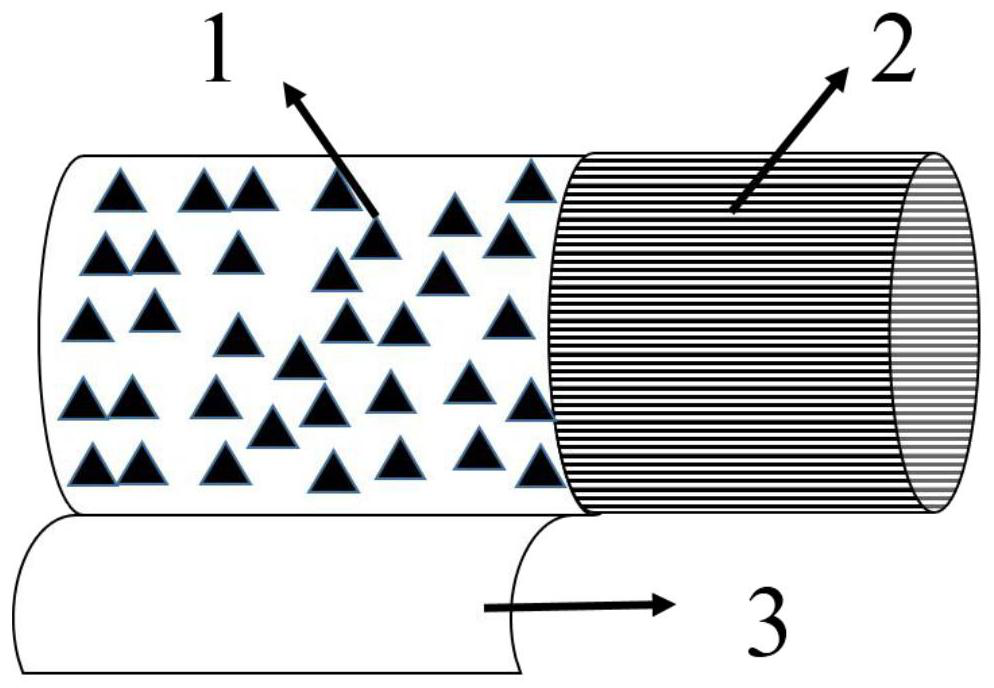

[0026] like figure 1 As shown, a method for preparing a nanofiber film / substrate fragment cigarette holder, specifically comprises the following steps:

[0027] (1) Preparation of nanofibers by electrospinning: configure cellulose acetate spinning solution with a mass concentration of 9%, and use a mixture of acetone and N,N-dimethylformamide as the spinning solution solvent. The mass ratio of acetone to N,N-dimethylformamide is 1:1, the spinning distance is adjusted to 19cm, and the voltage is 70kv to prepare acetate nanofibers;

[0028] (2) Preparation of nanofiber membrane / substrate composite layer: The acetate nanofibers prepared in step (1) are received by using a substrate, and the substrate used for receiving is cellulose acetate non-woven fabric, acetate nanofibers and acetate fibers The plain non-woven fabric constitutes the nanofiber membrane / substrate composite layer;

[0029] (3) Preparation of nanofiber membrane / substrate fragments: The nanofiber membrane / substr...

Embodiment 2

[0035] A method for preparing a nanofiber film / substrate fragment cigarette holder, specifically comprising the following steps:

[0036] (1) Preparation of the first nanofiber membrane / substrate fragments:

[0037] Step1: Preparation of chitosan nanofibers by electrospinning: prepare chitosan spinning solution with a mass concentration of 10%, use glacial acetic acid as the solvent of the spinning solution, adjust the spinning distance to 19cm, and the voltage to 70kv to prepare the shells. Polysaccharide nanofibers;

[0038]Step2: Preparation of nanofiber film / substrate composite layer: The chitosan nanofibers prepared in Step1 are received by the substrate, and the substrate used for receiving is absorbent paper, and the chitosan nanofibers are fixed on the water-absorbing paper by the spunlace method. On paper, the first nanofiber membrane / substrate composite layer is formed;

[0039] Step3: Preparation of the first nanofiber membrane / substrate fragment: The nanofiber me...

Embodiment 3

[0049] A method for preparing a nanofiber film / substrate fragment cigarette holder, specifically comprising the following steps:

[0050] (1) Preparation of nanofiber membrane / substrate fragments:

[0051] Step1: Preparation of polyvinyl alcohol nanofibers by electrospinning: prepare a polyvinyl alcohol spinning solution with a mass concentration of 11%, use water as the solvent of the spinning solution, adjust the spinning distance to 20 cm, and the voltage to 45 kV to prepare polyethylene Alcohol nanofibers;

[0052] Step2: Preparation of double-layer nanofiber membrane / substrate composite layer: The polyvinyl alcohol nanofibers prepared in Step1 are received by the substrate, and the substrate used for receiving is glass fiber membrane;

[0053] The polyvinyl alcohol spinning solution was replaced with a 9% concentration of chitin spinning solution, the spinning solution solvent was trifluoroacetic acid, the spinning distance was adjusted to 20 cm, and the voltage was 35 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com