A quaternary sulfide semiconductor photocatalytic material for antibacterial and anticorrosion of coastal concrete structures, its preparation method and application

A technology of concrete structure and photocatalytic materials, applied in semiconductor devices, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low ultraviolet light, achieve low raw material cost, mild reaction conditions, and simple and convenient operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] CsMnAs 3 S 6 The preparation method is: using cesium hydroxide monohydrate, metal manganese, binary solid solution arsenic trisulfide and elemental sulfur with a molar ratio of 1.0-2.0:1.0-2.0:0.5:2.0-3.5 as raw materials; 0.5-1.0: 2.0-3.5 85% hydrazine hydrate and oleic acid as solvents; add every 0.410-0.665 grams of raw materials into 2.5-4.5mL of the solvent in proportion, and react in an oven at 130-160°C for 4-7 Days, the quaternary sulfide semiconductor material CsMnAs was obtained after washing with deionized water and ethanol 3 S 6 .

[0021] In the following examples of the present invention, the binary solid solution arsenic trisulfide can be prepared by using existing materials or by the following method: As and S with a molar ratio of 2:3 are packed into a quartz tube to seal the tube, and then the sealed quartz tube Put it into a muffle furnace, slowly raise the temperature to 680°C, and keep it warm for 12 hours, then cool it down to room temperature ...

Embodiment 1

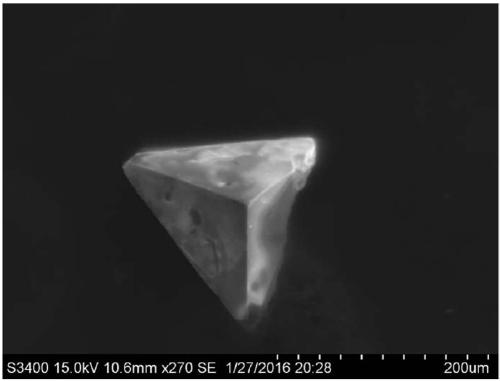

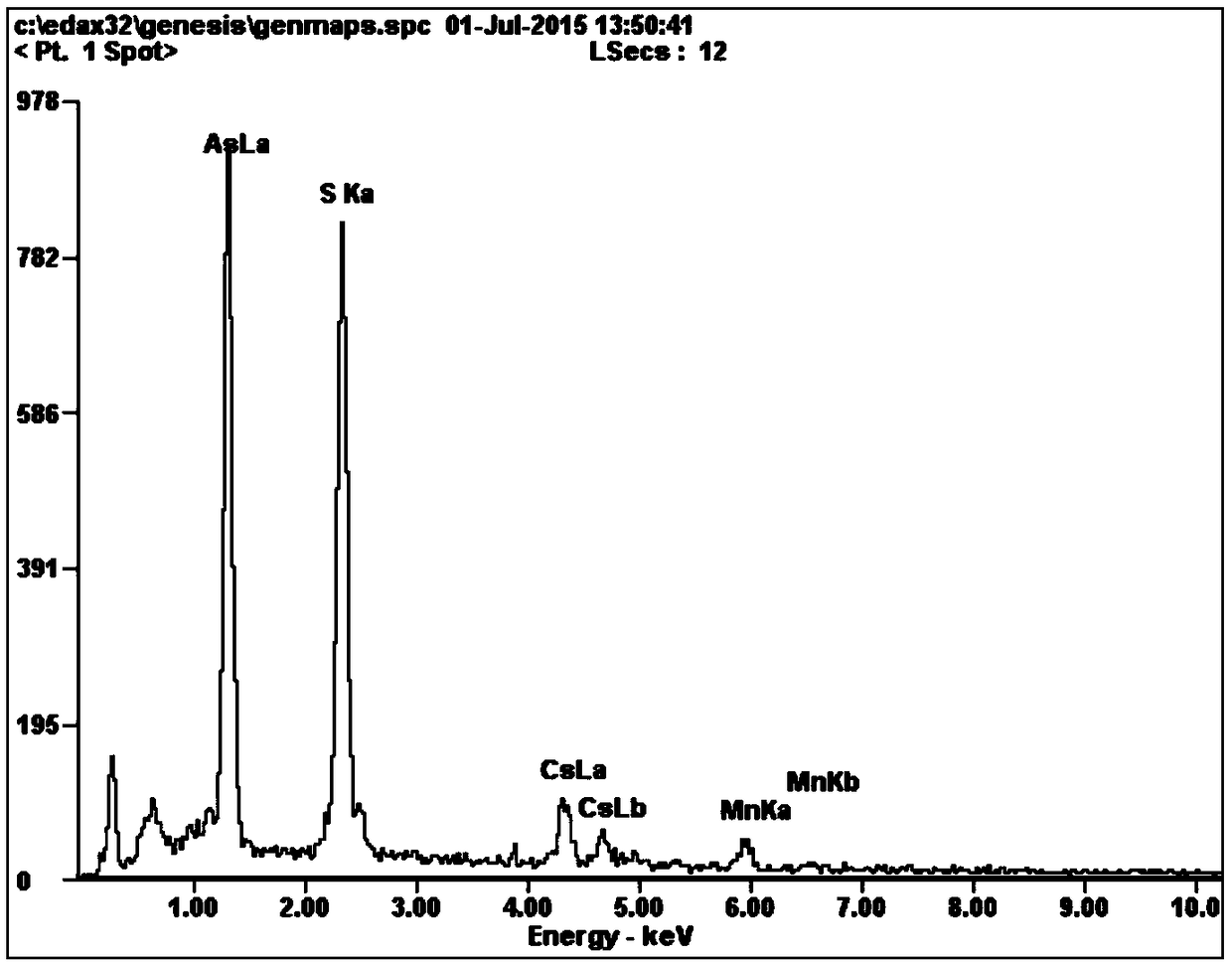

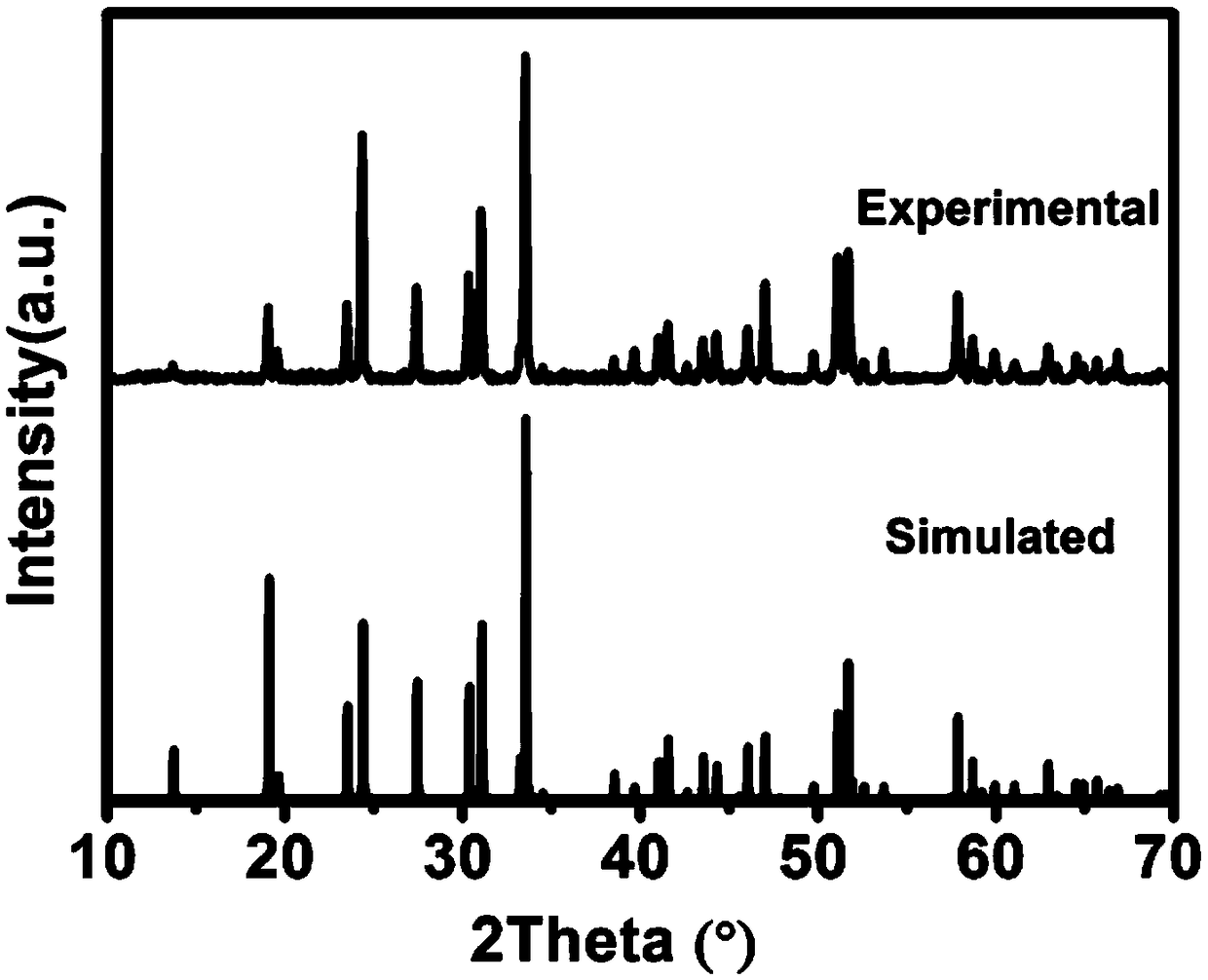

[0023] CsMnAs 3 S 6 crystals. Weigh the initial raw material CsOH·H 2 O 1.5mmol (0.252g), Mn 1.0mmol (0.055g), As 2 S 3 Put 0.5mmol (0.123g) and S 3.0mmol (0.096g) into a hydrothermal kettle, then add 0.5ml of 85% hydrazine hydrate and 2.0mL of oleic acid, and place the hydrothermal kettle at 140°C for 5 days. After the reaction was finished, the hydrothermal kettle was opened, the product was taken out, washed 2 times with distilled water and dehydrated alcohol respectively, to obtain orange blocky crystals, the productive rate was 90%, and the grain size was 150-300 μm (see figure 1 ). According to single crystal X-ray diffraction analysis, the crystal composition formula is CsMnAs 3 S 6 ,, R-3 space group, unit cell parameters α=90°, β=90°, γ=120°, Z=3, the crystal structure diagram is as follows image 3 shown. EDX elemental analysis showed that the crystal contained Cs, Mn, As, and S four elements, and the content ratio of each element was consistent with ...

Embodiment 2

[0026] CsMnAs 3 S 6 crystals. Weigh the initial raw material CsOH·H 2 O 2.0mmol (0.336g), Mn 1.0mmol (0.055g), As 2 S 3 Put 0.5mmol (0.123g) and S 2.5mmol (0.080g) into a hydrothermal kettle, then add hydrazine hydrate 0.5ml and oleic acid 2.0mL, and place the hydrothermal kettle at 140°C for 5 days. After the reaction, the hydrothermal kettle was opened, the product was taken out, and washed twice with distilled water and absolute ethanol respectively to obtain orange blocky crystals with a yield of 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com