Novel anti-winding self-cleaning crusher

A crusher, self-cleaning technology, applied in the direction of grain processing, etc., can solve the problems of blockage of the crusher, blockage of the sewer system, time-consuming and laborious odor, etc., to improve the service life of the equipment, easy maintenance and repair, and the grid overflows. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

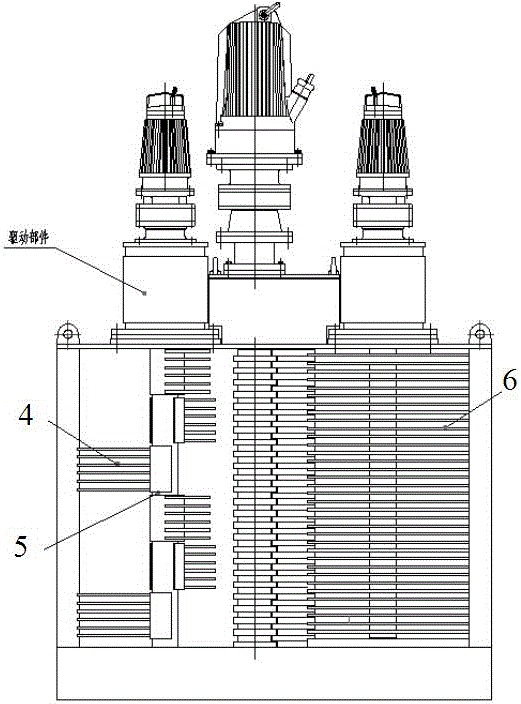

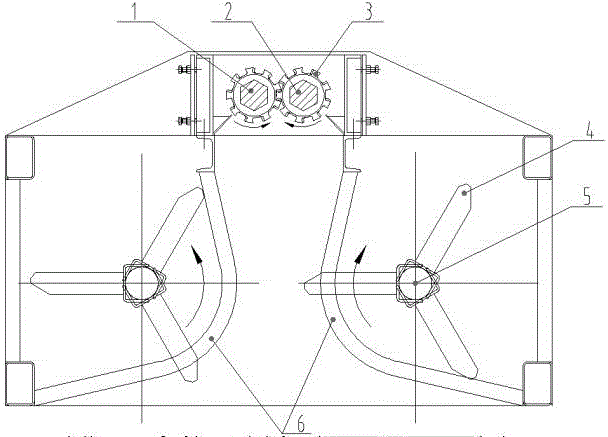

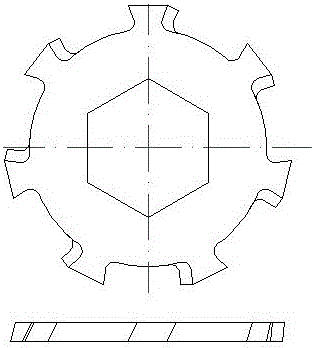

[0024] Such as Figure 1-5 As shown, an anti-winding self-cleaning crusher, the body of the crusher is provided with an interception area and a crushing area; the interception area is provided with a water-passing grid 6, and the water-passing grid 6 is arranged on the body on the upstream surface; the crushing area is located behind the interception area, and there are driving parts and cutting parts inside. The driving part is a motor, and the cutting part includes a main shaft 1 and a driven shaft 2, and the main shaft 1 and the driven shaft 2 are meshed through gears Transmission, the teeth of the gear are milling cutters 3; the output shaft of the motor is connected to drive the main shaft 1 to rotate; the water-passing grid 6 is an arc-shaped water-passing grid, and the center of the circular-arc-shaped water-passing grid The position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com