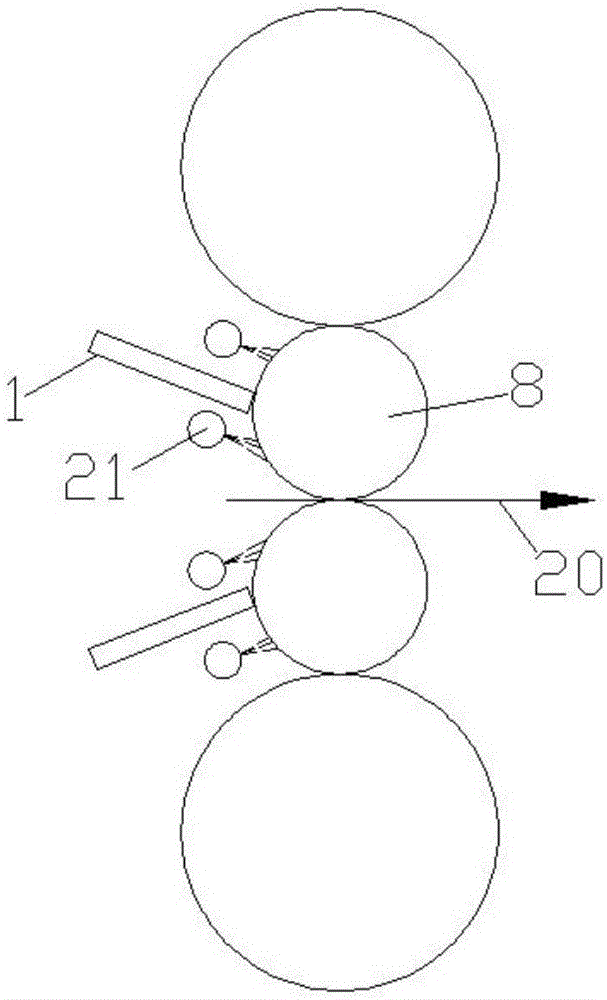

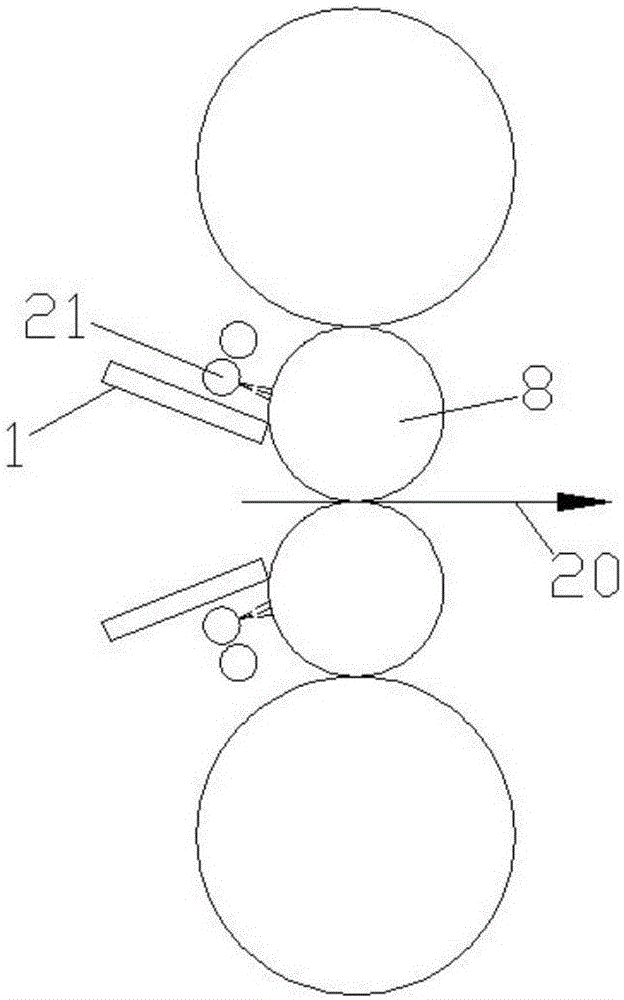

Hot rolling work roll water scraping fuel injection system and method

A technology of oil injection system and work roll, which is applied in the direction of rolls, metal rolling, manufacturing tools, etc. It can solve the problems of unfavorable work rolls, damage, broken belts and rolls, etc., to improve the effect of wiping water and lubricating the roll gap , avoid the impact damage of strip steel, and optimize the effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

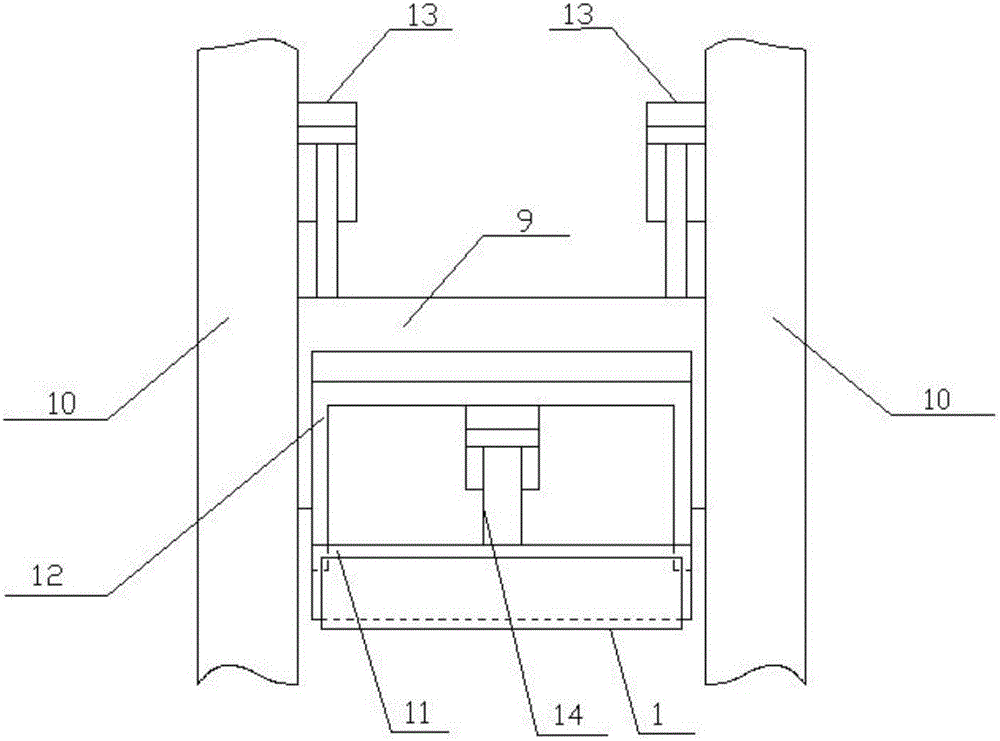

[0072] In order to make the principle of the method of the present invention clearer and easier to understand, the present invention is further described on the basis of Example 1.

[0073] This embodiment provides a method for wiping and spraying oil on hot rolling work rolls, which specifically includes the following steps:

[0074] Step 1. Provide the various components of the above-mentioned wiper oil injection system, and assemble the support frame 9, the first hydraulic cylinder 13, the second hydraulic cylinder 14, the guide mechanism and the wiper blade 1; wherein the wiper oil injection system The structure parameters are as follows:

[0075] The thickness of the wiper 1 is 200mm; the angle β between the chamfered surface 4 and the upper surface of the wiper 1 is 50°; the thickness of the wear-resistant material 5 is 4mm; the height of the groove 7 is 55mm; the diameter of the through hole 6 is 90mm; the outer diameter of the injection header 2 is 85mm, and the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com