A hot-melt glue injection head wire winding device

A glue-injecting and wire-winding technology is applied to the hot-melt glue-injection head wire winding device and the field of hot-melt glue-injection hair heating wire winding, which can solve the problem of heating wire breakage, difficult to guarantee processing quality, and loose heating wire fixation. and other problems, so as to avoid short lifespan, ensure quality control, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

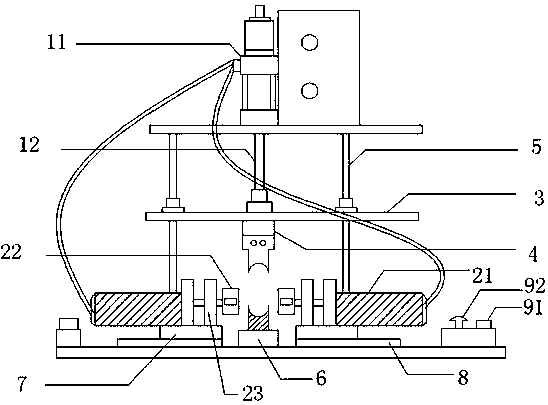

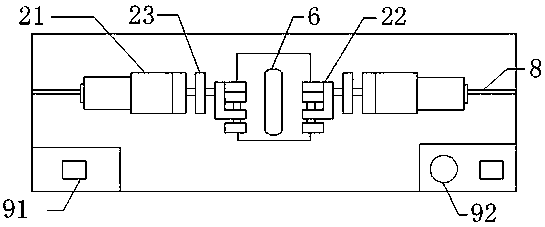

[0021] Such as Figure 1~2 As shown, the present invention discloses a hot-melt glue injection head wire winding device suitable for the glue injection head heating wire winding process, including a base, a switch, a product fixing component and a heating wire winding component.

[0022] The switch includes a two-hand start button 91 arranged at two ends of the base, and a stop button 92 arranged at one side of the base. The two-hand start button 91 requires the operator to press the switch with both hands simultaneously when starting the machine. Such a setting can better ensure that the device will not start by mistake due to improper operation, and ensures the stability of the overall operation of the device. At the same time, the stop button 92 can easily stop the operation of the device, which can ensure that the operator can stop and operate in time when a certain failure occurs in the machine, and carry out corresponding troubleshooting in time.

[0023] The product fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com