Adjustable magnetic force gate type fluid lining surrounding rock pressure relief device and construction method

A pressure relief device and fluid mass technology, applied in valve device, wellbore lining, tunnel lining and other directions, can solve the problems of high construction cost of high ground stress soft rock tunnel, uneven support structure stress, uneven ground stress and other problems , to achieve the effect of simple structure, detachable operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

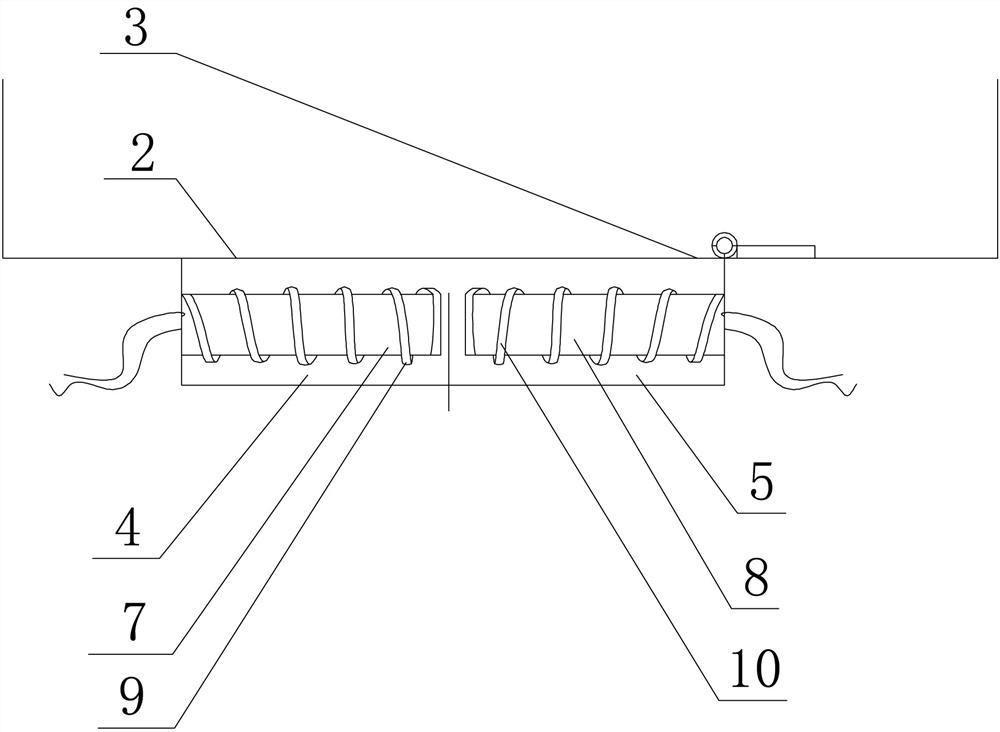

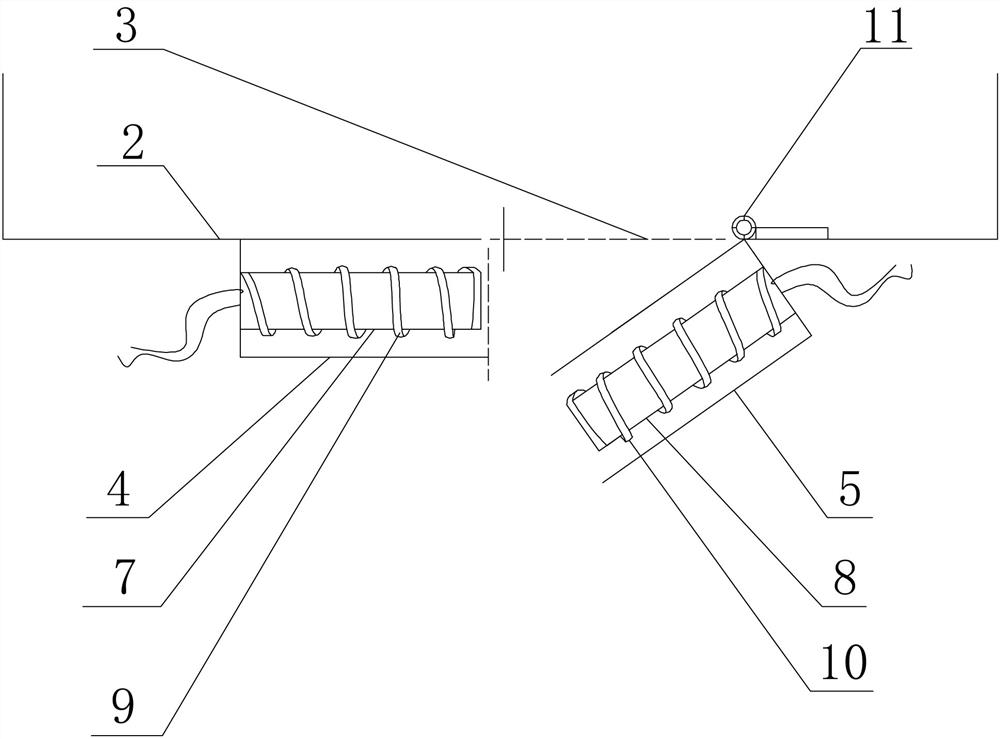

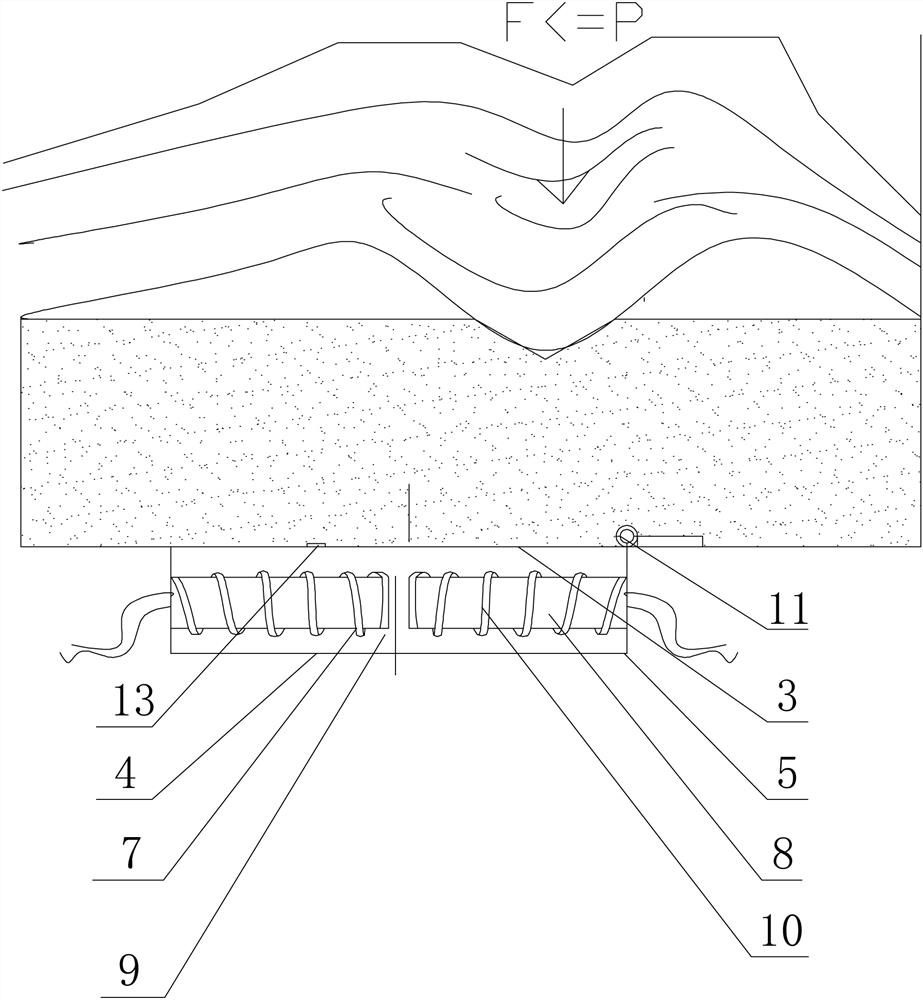

[0037] Such as Figure 1-6As shown, the door-type fluid lining surrounding rock pressure relief device with adjustable magnetic force includes a tunnel lining 16, and the inner side wall of the tunnel lining 16 is anchored with a channel steel 2 through an initial lining bolt 15, and the channel steel 2 and The tunnel lining 16 is filled with fluid fillers 1, and the channel steel 2 is provided with a plurality of fluid outlet holes 3 at different positions, and the position of the fluid outlet holes 3 is equipped with a The stress of 1 is self-feedback pressure relief valve 6. By adopting the above-mentioned surrounding rock pressure relief device, the fluid filling material 1 acts on the secondary lining in advance to reduce the load generated by the stress deformation of the surrounding rock to reduce the amount of creep deformation and shorten the deformation stabilization period. When the surrounding rock pressure increases, the stress self-feedback pressure relief valve...

Embodiment 2

[0046] The construction method of any one of the adjustable magnetic door type fluid lining surrounding rock pressure relief device, it includes the following steps:

[0047] Step1, material preparation: sand, gravel, cystic substance, channel steel, steel sheet, electromagnet, energized coil wire, hinge, controller, pressure sensor;

[0048] Step2: The manufacturing mechanism of the grouting hole 14 on the channel steel 2 and the fluid release hole 3: the grouting hole 14 on the channel steel 2 is manually opened and closed by plugging, and the fluid release hole 3 on the channel steel 2 is not In the working state, due to the opposite sex attraction of the electromagnetic locking device, it is in the closed state. In the working state, due to the current control of the energized coil, the suction and repulsion between the electromagnetic locking device is controlled to control the closing and opening of the door electromagnet;

[0049] Step3: Fixing of the channel steel 2: T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com