Machining technology of perforated rotating shaft body part

A processing technology and part technology, which is applied in the field of forging processing technology of perforated shaft body parts, can solve the problems of large difference in grain size, shrinkage cavity, shrinkage porosity, inclusions, coarse grains, etc., and achieves a comprehensive flow direction. Improved performance, guaranteed application reliability, and improved organizational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

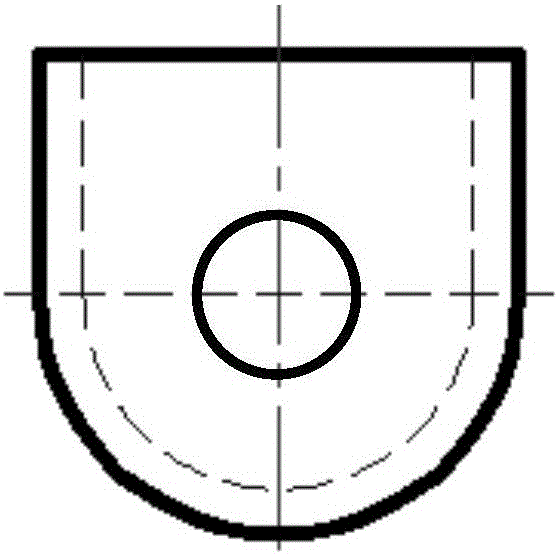

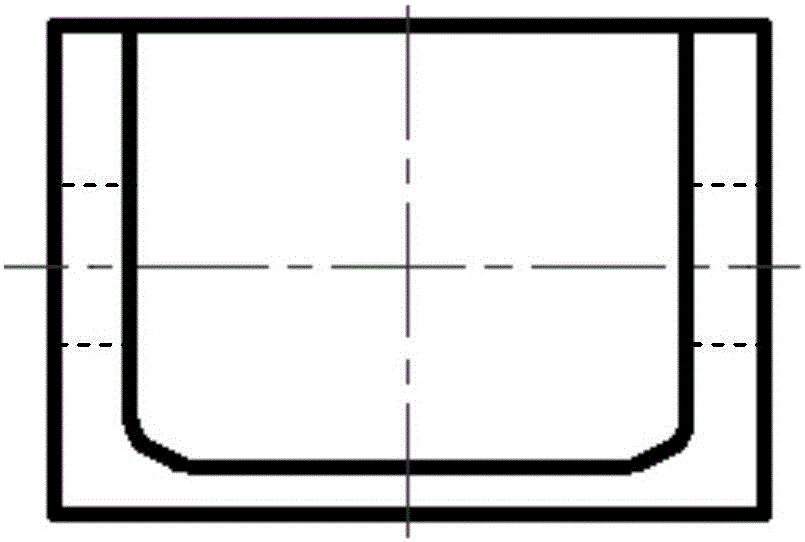

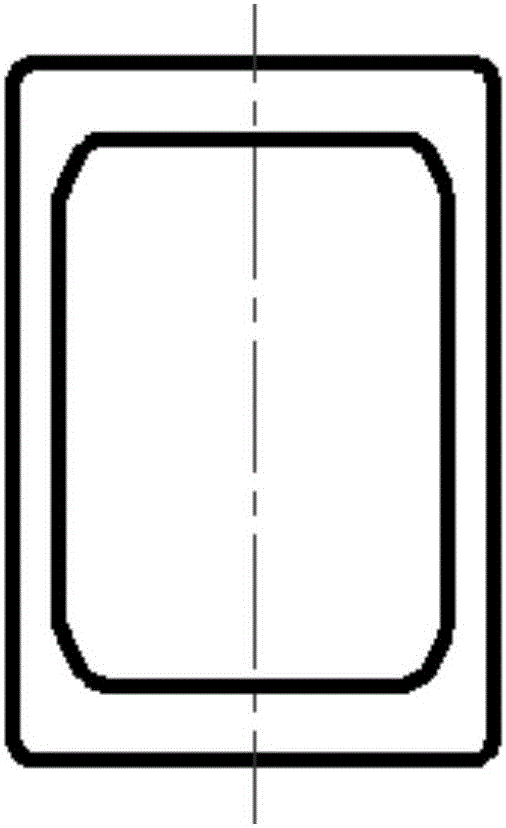

[0022] Forging is a processing method that uses forging machinery to exert pressure on metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. Forging can eliminate defects such as loose casting of metals during the smelting process, optimize At the same time, due to the preservation of complete metal flow lines, the mechanical properties of forgings are generally better than castings of the same material. The bottom of the perforated rotating shaft part to be processed in the present invention has a circular arc structure, and the thickness of the edge is uneven. Forging such parts often has problems such as difficulty in filling the bottom and excessive height difference between the edges. Aiming at the structural features of the perforated rotating shaft body part, after theoretical design and repeated processing verification, the present invention provides an integral forging process based on a round bar bla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap