Enhanced multi-axis finish milling device

An enhanced, fine-milling technology, applied in positioning devices, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of increasing production costs and maintenance costs, reducing processing efficiency, and product quality, and achieving flexible and changeable clamping. scheme, improve processing accuracy, and achieve the effect of stereo positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

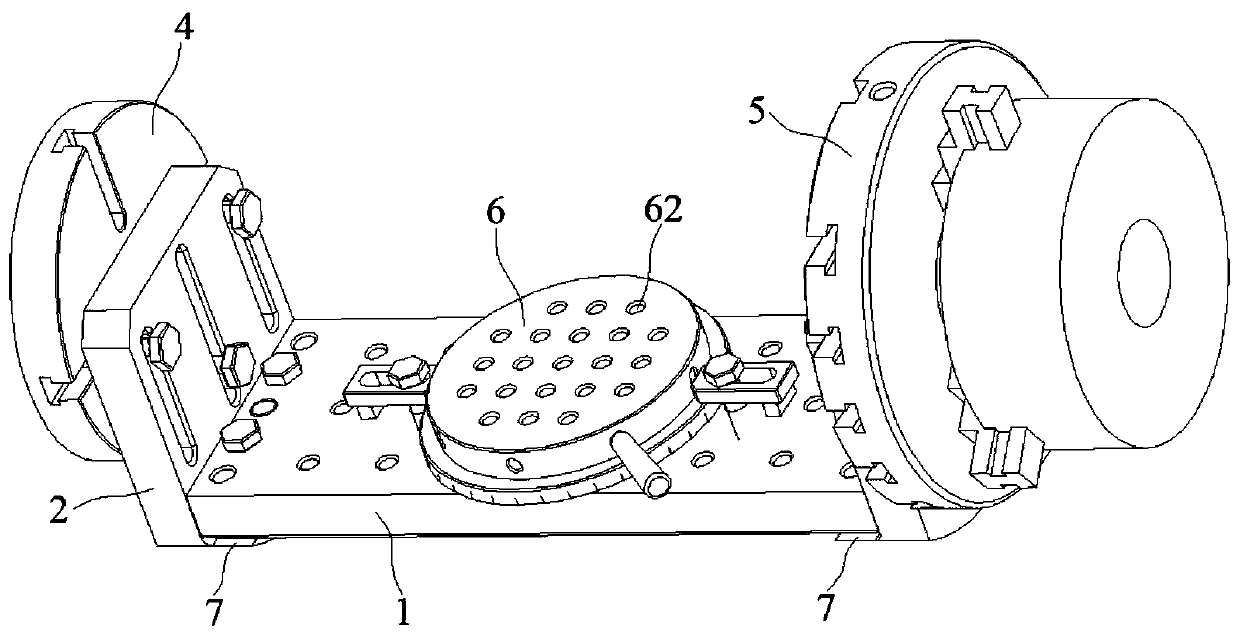

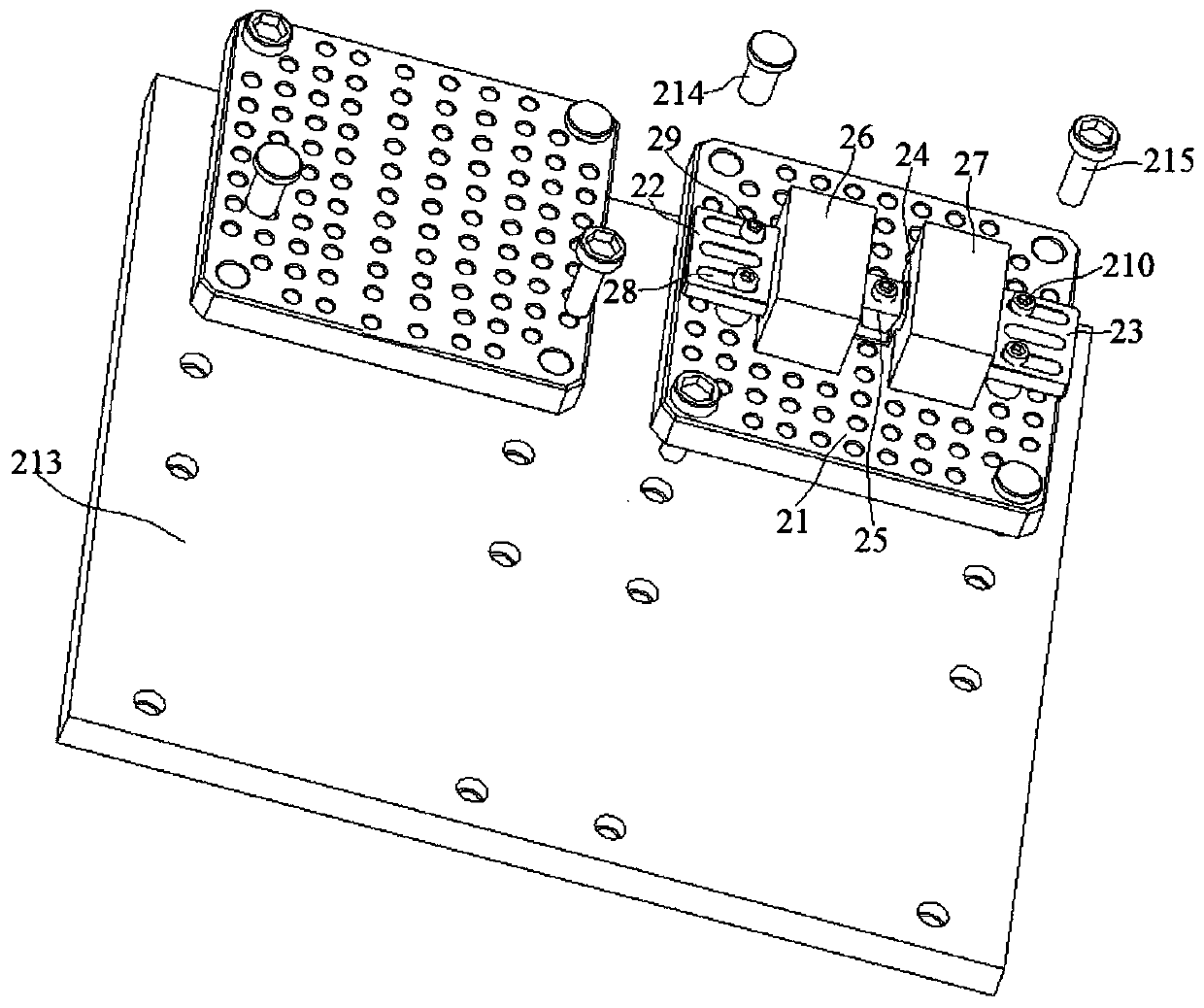

[0027] Embodiment 1: An enhanced multi-axis fine milling device, including a base plate 1, a left side plate 2, a right side plate 3, a left connecting plate 4, a right connecting plate 5, a ball lock clamping mechanism and an upper surface of the base plate 1 flange plate 6, the lower part of the left side plate 2 and the right side plate 3 has a bottom convex strip 7, the base plate 1 is located between the left side plate 2 and the right side plate 3, and the two ends of the base plate 1 are respectively installed on On the upper surface of the bottom convex strip 7 of the left side plate 2 and the right side plate 3, the left connecting plate 4 is installed on the surface of the left side plate 2 opposite to the base plate 1, and the right connecting plate 5 is installed on the right side plate 3 the surface opposite to the substrate 1;

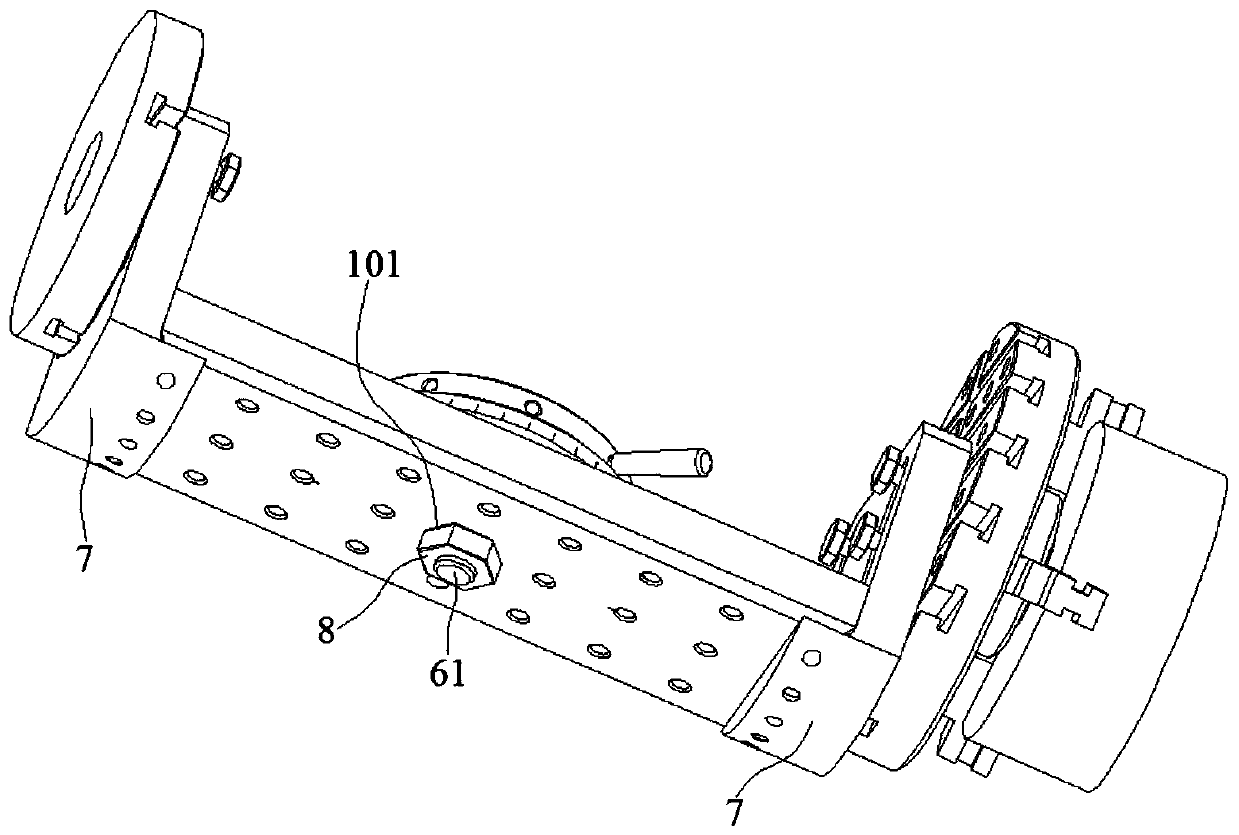

[0028] A central bolt 61 is fixed at the bottom of the flange 6, and a central through hole 101 is opened in the central area of the s...

Embodiment 2

[0035] Embodiment 2: An enhanced multi-axis fine milling device, including a base plate 1, a left side plate 2, a right side plate 3, a left connecting plate 4, a right connecting plate 5, a ball lock clamping mechanism and an upper surface of the base plate 1 flange plate 6, the lower part of the left side plate 2 and the right side plate 3 has a bottom convex strip 7, the base plate 1 is located between the left side plate 2 and the right side plate 3, and the two ends of the base plate 1 are respectively installed on On the upper surface of the bottom convex strip 7 of the left side plate 2 and the right side plate 3, the left connecting plate 4 is installed on the surface of the left side plate 2 opposite to the base plate 1, and the right connecting plate 5 is installed on the right side plate 3 the surface opposite to the substrate 1;

[0036] A central bolt 61 is fixed at the bottom of the flange 6, and a central through hole 101 is opened in the central area of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com