Device for producing single-color printed fabric based on projection and operation method

An operation method and fabric technology, applied in printing devices, printing, typewriters, etc., can solve the problems of slow speed, complex downstream processing of dye ink digital printing, high water and energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

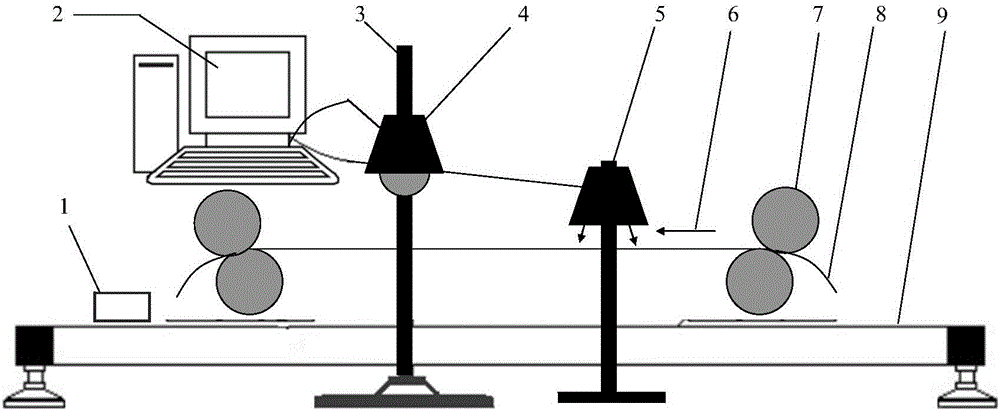

[0023] The invention provides a device and an operation method for producing monochrome printed fabrics based on projection, which is characterized in that: it includes at least one unit for producing monochrome printed fabrics by projection installed on a frame (9); The unit includes a PC (2) connected to the controller (1) through a communication line. During the production process, the controller controls the spraying action of the sprinkler head (5) and the projector (4) projects images, and at the same time the controller controls the roller (7 ), the fabric (9) is transported in the direction indicated by the arrow with the rotation gap of the drum, and the adjustable bracket (3) is used to adjust the distance between the sprinkler head and the projector and the fabric; the operation method is through the PC Send action instructions to the controller, and the controller controls the spray head to spray photocurable resin onto the surface of the fabric, and after the proje...

Embodiment 2

[0026] The invention provides a device and an operation method for producing monochrome printed fabrics based on projection, which is characterized in that: it includes at least one unit for producing monochrome printed fabrics by projection installed on a support (9); the unit for producing monochrome printed fabrics by projection The PC (2) is connected to the controller (1) through a communication line. During the production process, the controller controls the spraying action of the sprinkler head (5) and the projector (4) projects images, and at the same time the controller controls the roller (7) Gap rotation movement, the fabric (9) is conveyed in the direction of the arrow with the rotation gap of the drum, and the adjustable bracket (3) is used to adjust the distance between the sprinkler head and the projector and the fabric; the operation method is to use the PC to The controller transmits action instructions, and the controller controls the spray head to spray the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com