A rail flat car frame

A flat car and frame technology, which is applied to locomotives, underframes, motor vehicles, etc., can solve the problems of high structural strength, insufficient structural platform, large loading volume and cargo loading restrictions, and achieve convenient maintenance and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and are therefore only used as examples, and cannot be used to limit the protection scope of the present invention.

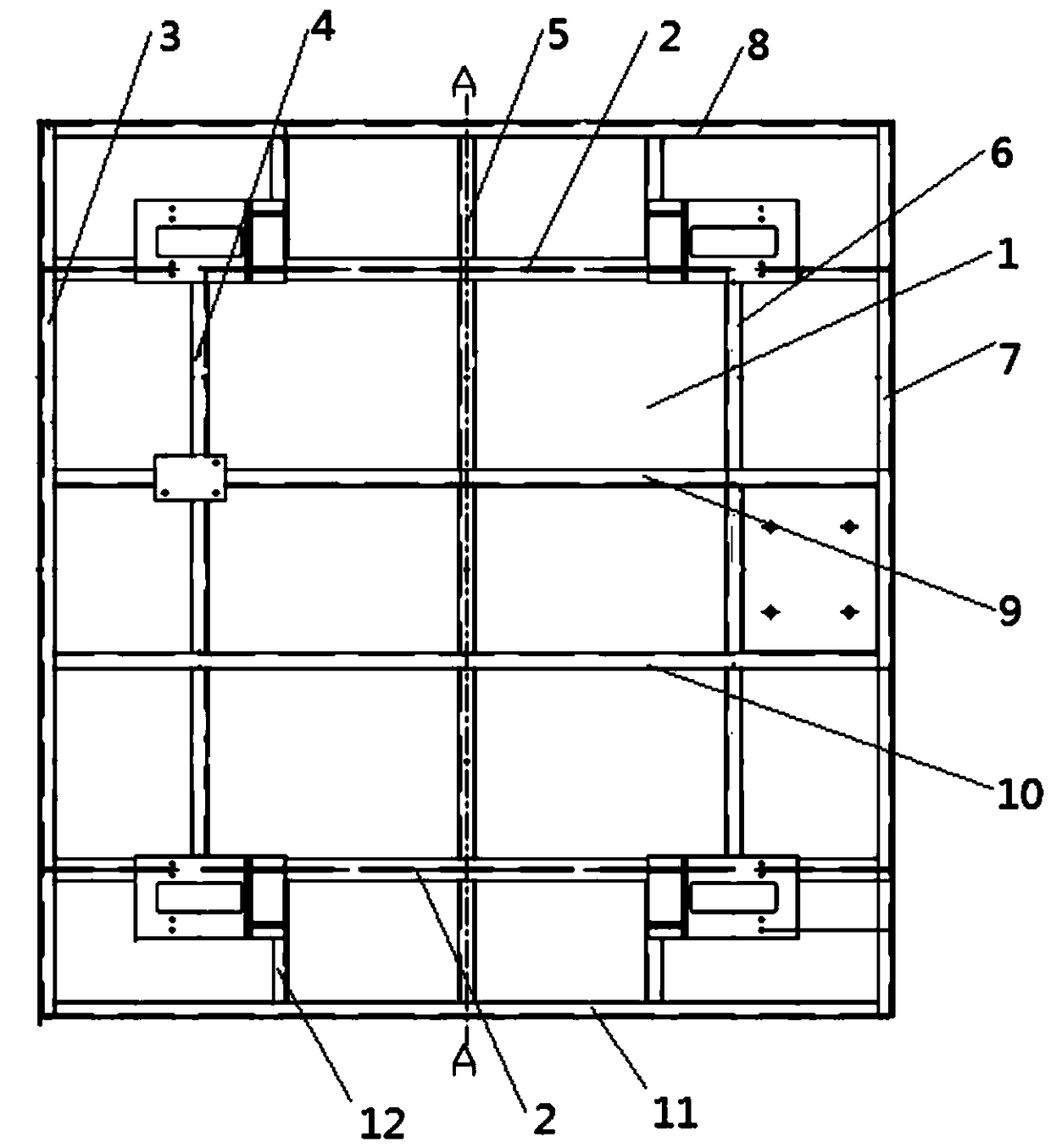

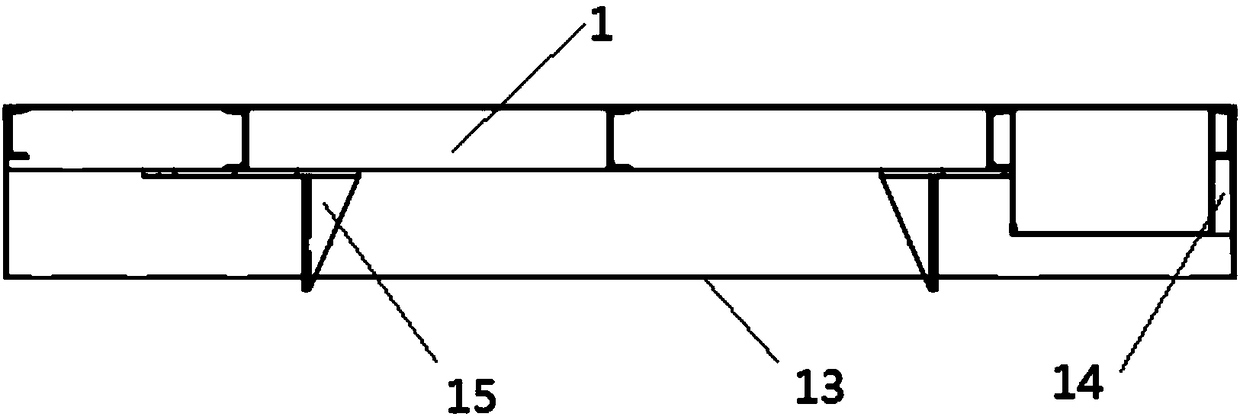

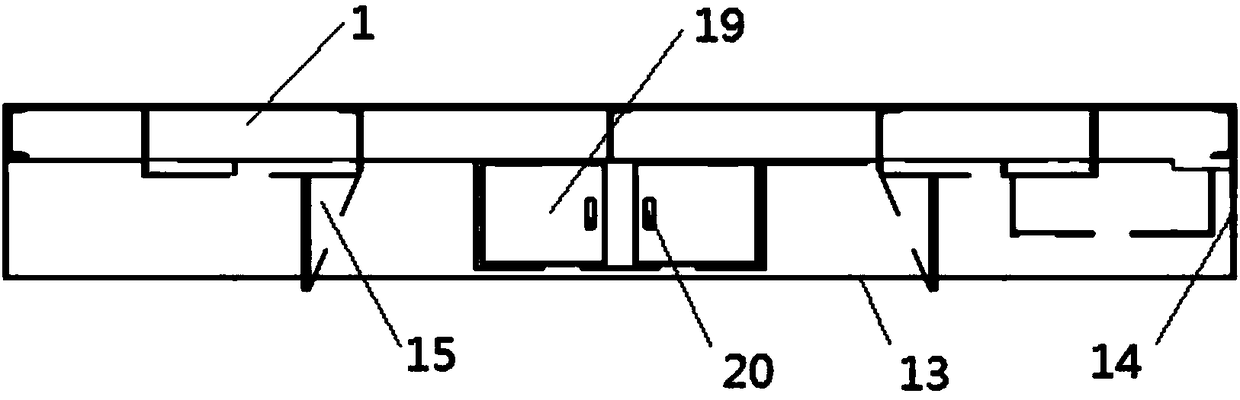

[0024] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a rail flat car frame, including an object bearing plate 1, an I-beam 2, a channel steel beam, a bottom plate 13, a side plate 14, a bearing seat bracket 15, a reducer seat 16; an object bearing plate 1 is a double-layer plate, and the cavity of the object plate 1 is provided with an I-beam 2 and a channel beam; the I-beam 2 has two and is symmetrically arranged on both sides of the lateral center line of the object plate 1, and the channel beam includes Longitudinal channel beam and transverse channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com