External windshield and rail vehicle with same

A rail vehicle and outer windshield technology, which is applied in the field of rail vehicles, can solve problems such as rapid paint aging, inconvenient installation, and reduced structural strength of the windshield, and achieve the effects of good structural strength, long service life, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

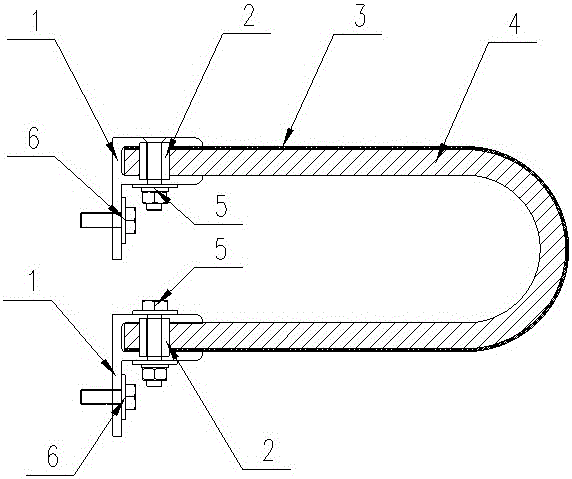

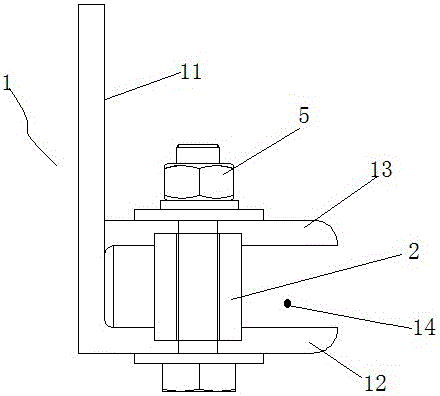

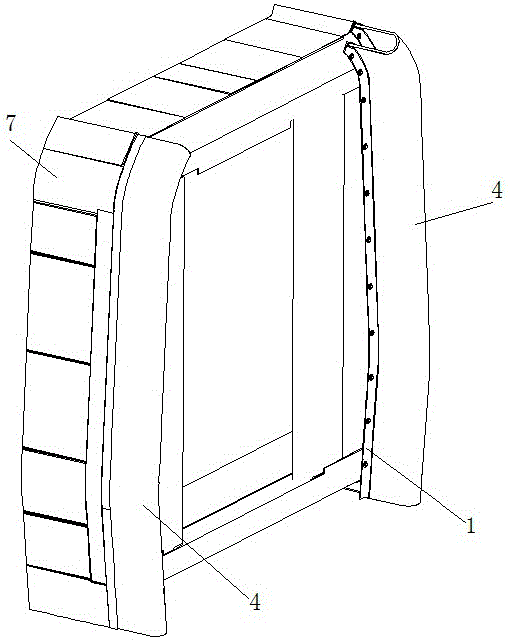

[0039] Such as Figure 1~4 As shown, an outer windshield includes a rubber bladder 4 and two mounting seats 1 arranged in parallel. The mounting seat 1 is F-shaped in cross section, and includes a strip body 11, a first vertical portion 12 and a second vertical portion 13 perpendicular to the strip body 11 and arranged in parallel. A groove 14 is formed between the straight portion 12 and the second vertical portion 13 .

[0040] The two sides of the rubber bag 4 are respectively inserted into the grooves 14 of the two parallel mounts 1, and the two sides of the rubber bag 4 and the grooves 14 inserted therein are interference fit and fixed in the grooves 14. .

[0041] The outer surface of the rubber bladder 4 is provided with a wear-resistant layer 3 . Preferably, the wear-resistant layer 3 is a wear-resistant tarpaulin.

[0042] The two sides of the rubber bag 4 and the groove 14 are fixed by bolts 5 , and the bolts 5 vertically pass through the first vertical portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com