Horizontal winding packaging machine

A packaging machine, horizontal technology, applied in the field of horizontal winding packaging machines, can solve the problems of items not being properly protected, reduce the workload of entrepreneurs, waste packaging materials, etc., to improve packaging quality and solve manual packaging efficiency. The effect of low and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

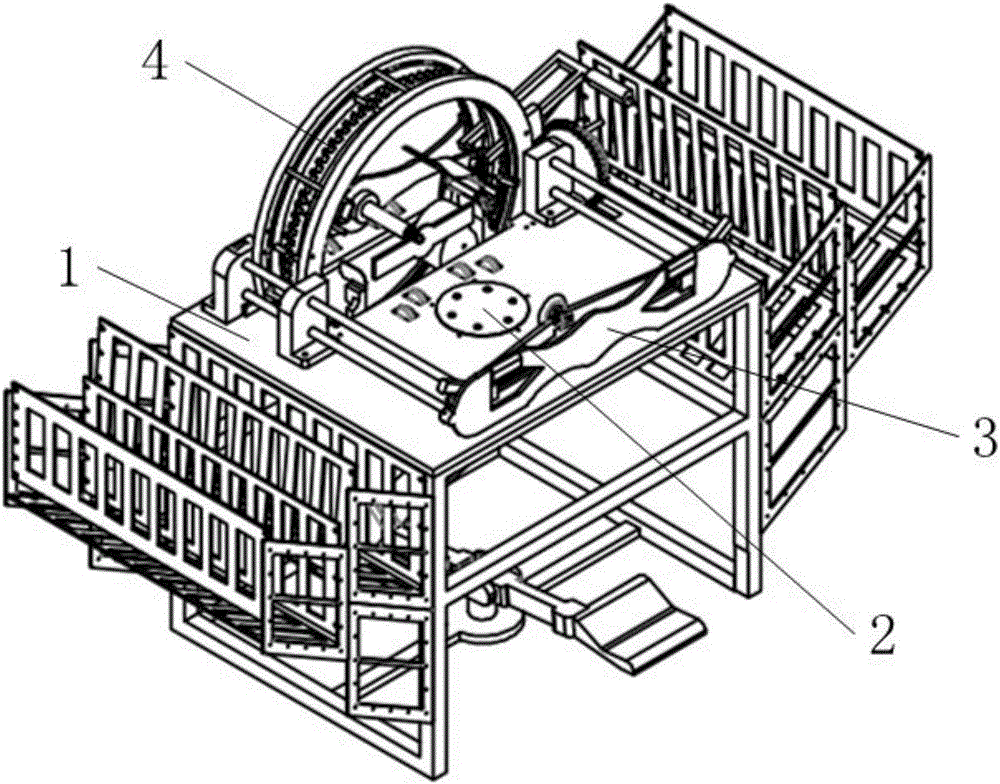

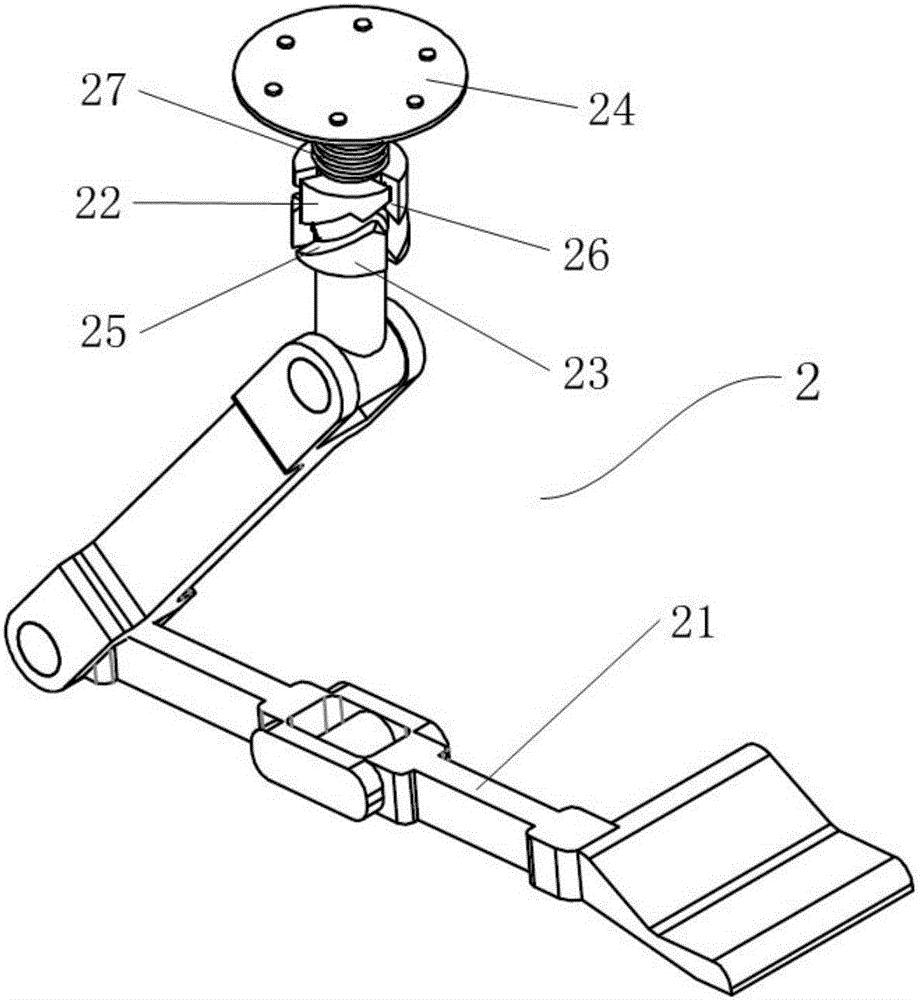

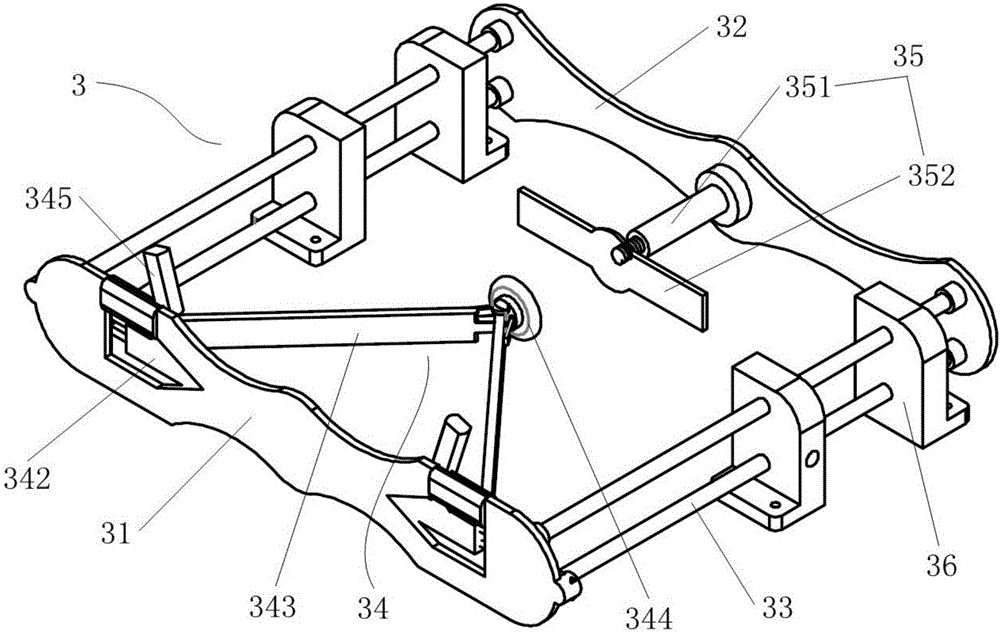

[0021] As shown in the figure, the horizontal wrapping packaging machine in the present invention includes a stand 1, a stage system 2, a motion positioning system 3 and a rotary winding system 4, and the motion positioning system 3 is arranged above the stand 1, so that The rotary winding system 4 is vertically arranged on the platform 1 and located in the motion positioning system 3 , and the stage system 2 is arranged in front of the rotary winding system 4 .

[0022] This packaging machine adopts the concept of horizontal winding packaging. After placing the object on the liftable stage system 2, the object to be packed is fixed by the motion positioning system 3, and then the fixed object to be packed is moved horizontally to the rotary winding system. After 4 centers, turn the rotary winding system 4 to wrap the plastic bubble wrap on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com