Direct-drive roller sewing machine

A technology of roller car and pull rod, which is applied in the field of sewing machines, can solve the problems of complex assembly, many parts, and high failure rate, and achieve the effects of improving work efficiency, convenient use, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

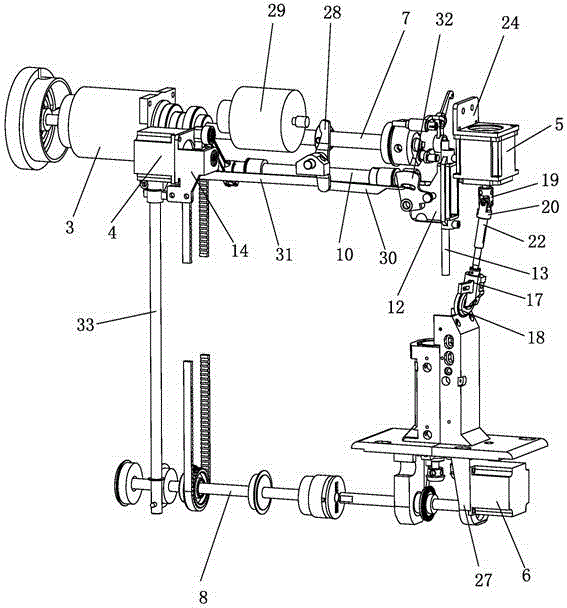

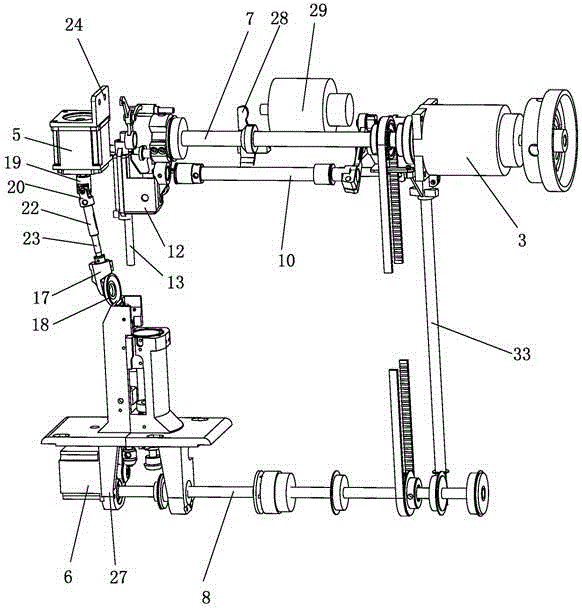

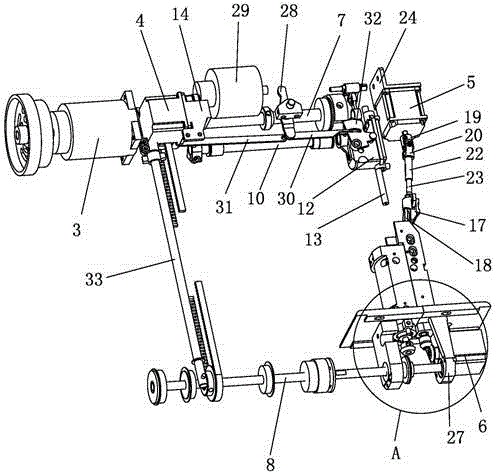

[0032] The present invention will be further described below with specific embodiment, see figure 1 -7:

[0033] A kind of direct-drive roller cart, comprising a main shaft mechanism, a needle bar swing mechanism 1, an upper feeding mechanism 2 and a lower feeding mechanism, the main shaft mechanism is driven by a main shaft motor 3, the needle bar swing mechanism 1 is driven by a needle bar swing motor 4, The upper feeding mechanism 2 is driven by the upper feeding motor 5, and the lower feeding mechanism is driven by the lower feeding motor 6. The main shaft motor 3, the needle bar swing motor 4, the upper feeding motor 5 and the lower feeding motor 6 are controlled by the controller to move independently or interact with each other. Cooperate with exercise.

[0034] Specifically, the main shaft mechanism includes a main shaft 7, the main shaft 7 is connected with the main shaft motor 3, the main shaft 7 is connected with the lower shaft 8 through a transmission mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com