Energy-saving oven for hot air stenter

A hot air tenter and setting machine technology, applied in the direction of fabric elongation, heating/cooling fabric, textile and paper making, etc., can solve the problems of increasing equipment volume and cost, high overall energy consumption, and high overall power consumption, and achieves dust removal. Efficient work, saving water resources, heating up and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

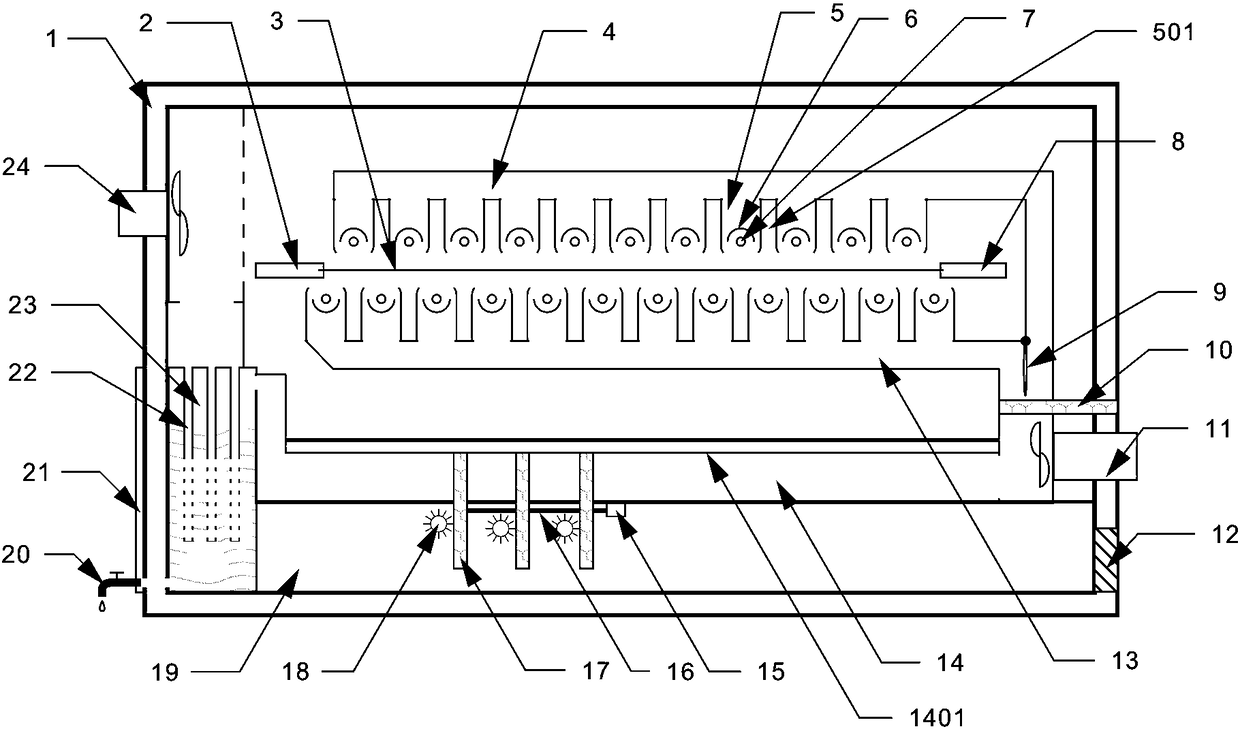

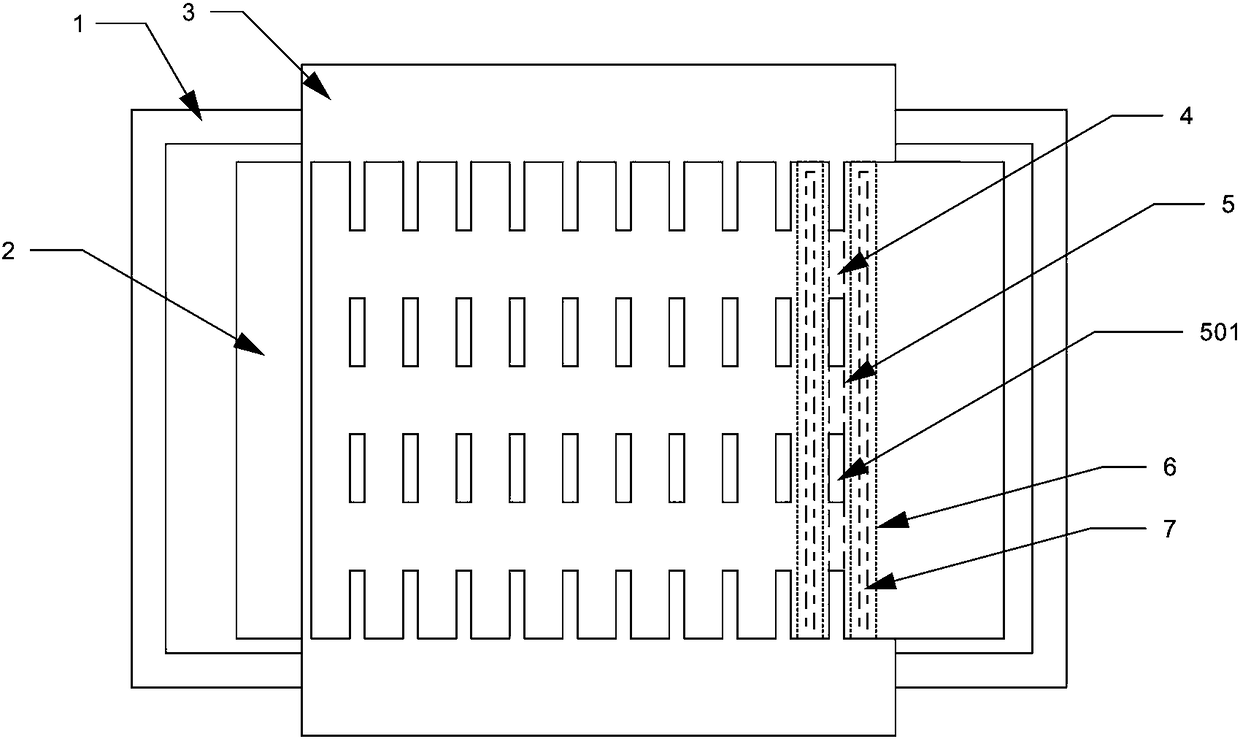

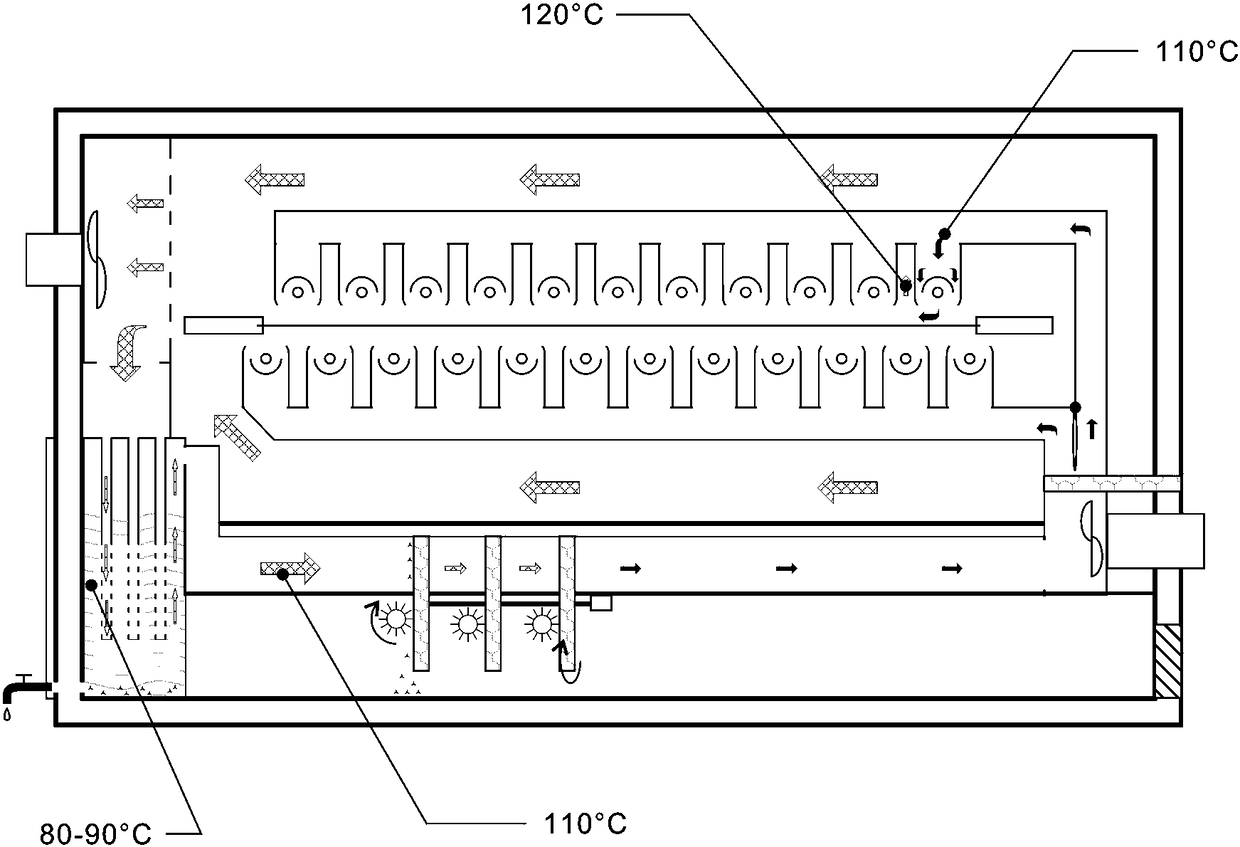

[0043] Such as figure 1 As shown, the embodiment of the energy-saving oven of the hot air stenter setting machine of the present invention has a cloth clamping track 2 and a cloth clamping track 8 on both sides in the oven box 1 of heat insulation and heat preservation, and the cloth 3 is clamped by the cloth clamping tracks on both sides. Suspended in the air and transported to the rear, there is an upper air duct 4 above the fabric 3, and a lower air duct 13 below. The upper air duct 4 and the lower air duct 13 have multiple air outlets 5 facing the fabric, and there are infrared lamps inside the air outlet 5 7. There is a metal curved reflector 6 behind the infrared lamp tube 7 .

[0044] The infrared light wave of the infrared lamp tube 7 can directly heat the surface and the inside of the cloth 3, so that the overall temperature of the cloth 3 is evenly heated inside and outside, the temperature rises quickly, and the heat energy is concentrated.

[0045] The metal curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com