Microwave drier and microwave drying method

A microwave drying and dryer technology, which is used in drying solid materials, drying gas layout, heating to dry solid materials, etc., can solve the problems of long drying time and inability to continuously feed materials, and achieve operating costs and losses. Low, fast and uniform heating in all directions, low operating costs and low losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

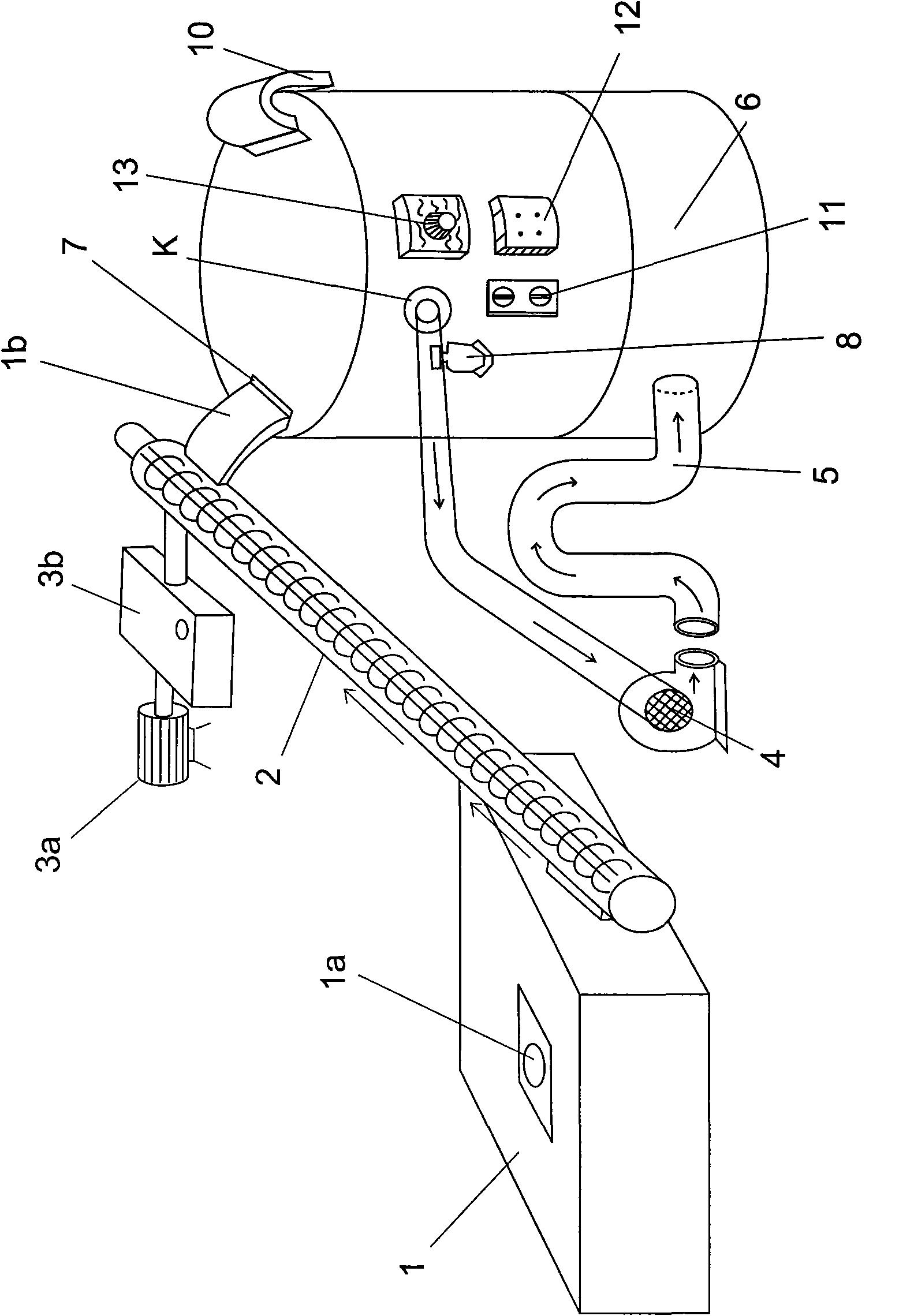

[0039] The following briefly describes the definition of microwave frequency, the corresponding wavelength range and related laws. On the basis of the basic equations, deduce the wave equation and solve some related problems, and then introduce the concepts of microwave penetration depth and energy absorption, the relationship between these two concepts and the thermal effect generated between microwaves and materials, and then analyze the microwave The general devices used, including microwave sources, waveguides, and radiators, are briefly introduced.

[0040] Microwave is an electromagnetic wave with a frequency of 300MHz to 300GHz, which is between low-frequency radio waves and high-frequency infrared rays and visible light, so microwaves are non-ionizing radiation. A microwave system generally consists of three main components, including a microwave source, a waveguide, and a radiator.

[0041] Microwave source: the magnetron, which is composed of a vacuum tube, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com