Induction remelting machine tool

A machine tool and remelting technology, applied in the field of machine tools, can solve the problems of uneven preheating and heating of workpieces, inaccurate control of remelting temperature, unstable product quality, etc., and achieve low manufacturing costs, small workpiece deformation, and remelting high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

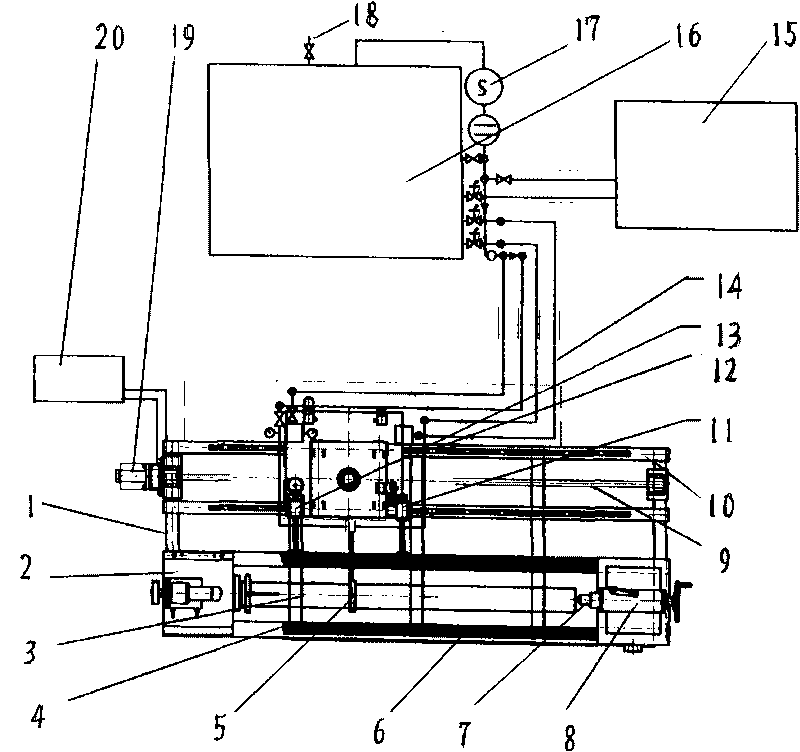

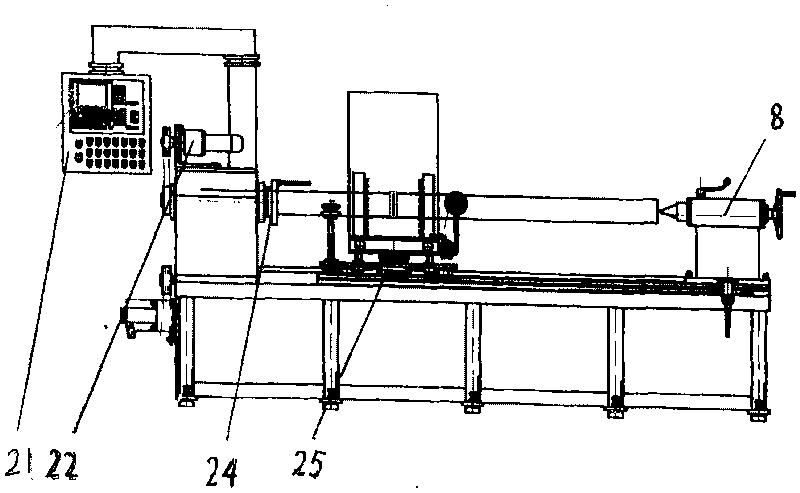

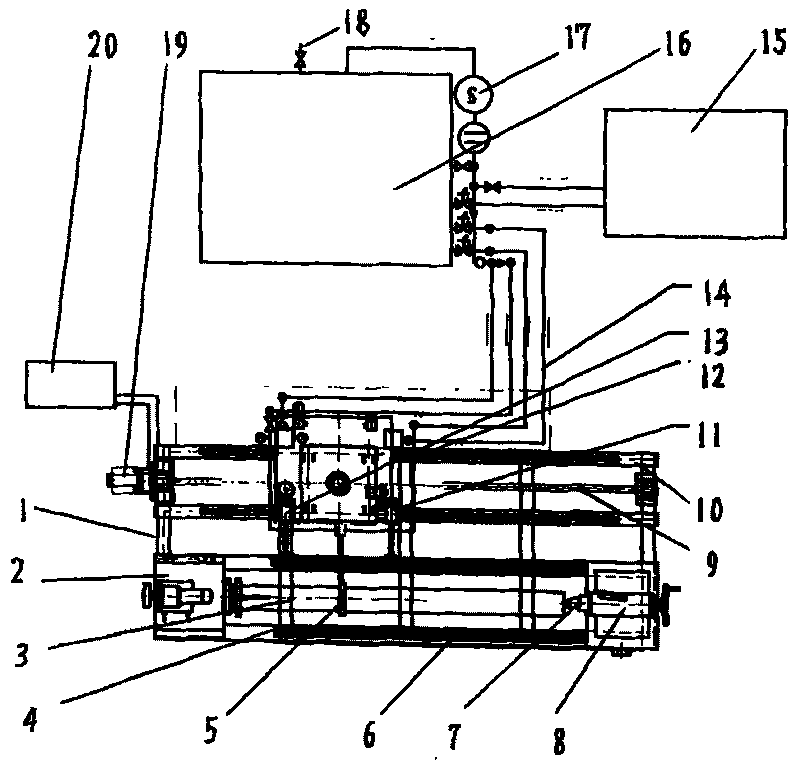

[0011] figure 1 , figure 2 Among them, the present invention includes a workpiece moving / rotating mechanism and an induction heating moving mechanism.

[0012] Workpiece moving / rotating mechanism: the machine tool body 1 has a spindle box 2 and a tailstock 8 which are arranged opposite to each other and are used to clamp the workpiece 3 and drive the workpiece 3 to rotate. The machine guide rail 4 can make the tailstock move axially. The tailstock 8 is equipped with the top sleeve 7 that can automatically expand and contract to meet the thermal expansion requirements of the workpiece. A chuck 24 that can drive the workpiece 3 to rotate is arranged on the spindle box 2 . The spindle box 2 is connected with the numerical control system 21 . The workpiece 3 clamped by the headstock 2 and the tailstock 8 is inserted into the inductor 5 capable of heating the workpiece. 22 is the main shaft box variable frequency motor.

[0013] The sensor heating moving mechanism is: the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com